Illumination: Ongoing developments for LEDs in signs and displays

by all | 1 December 2014 11:07 am

[1]

[1]Photo by Pedro Szekely, licensed under Creative Commons

By Stephen Montgomery

Light-emitting diodes (LEDs) are used in a variety of both stationary and mobile signs and displays. They have become integral components of illuminated building façades, stadium scoreboards, large outdoor digital billboards, smaller indoor retail displays, taxi signs, restaurant and supermarket signs, internally illuminated and halo-lit channel letters, sign cabinets and boxes, destination signs on mass transit vehicles and backlit liquid crystal display (LCD) screens used for professional display purposes.

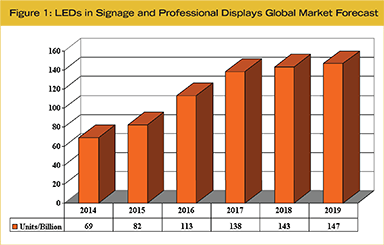

Market research has shown the worldwide volume of packaged LEDs sold for use in signs and other professional displays, in terms of quantity, was expected to reach 69 billion units in 2014. Consumption value is also predicted to increase, but with the rising growth in quantity largely offset by declining average unit prices. The global market consumption of packaged LEDs is forecast to reach 147 billion units in 2019 (see Figure 1).

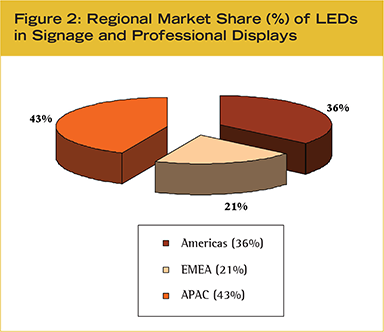

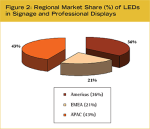

In terms of the aforementioned consumption value, the Asia-Pacific (APAC) region is the leader in relative market share, with 43 per cent in 2014 (see Figure 2), followed by the Americas—including North and South—and Europe, the Middle East and Africa (EMEA).

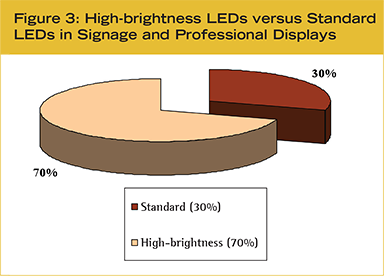

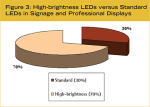

The LEDs used in signage and professional displays include both high-brightness (HB) and standard component-level bulbs. The HB LEDs are rated at 30 lumens per watt (lm/W) or greater, while the standard types are rated for less than 30 lm/W.

The HB LED category is the current sales leader in terms of consumption value, accounting for 70 per cent of relative market share in 2014 (see Figure 3), compared to the remaining 30 per cent for standard-type LEDs.

The following are just a few examples of how today’s increasing volumes of LEDs are being used throughout the sign and display industry.

Static signage

As a key visual landmark for consumers, bright and evenly illuminated outdoor signage is crucial to the brand images of countless businesses and stores. There are many ways to illuminate a sign by day and night, including not only LEDs, but also more traditional neon, fluorescent and electroluminescent (EL) systems. There are also different techniques for lighting signs, including from the back, from the front, along the edges and the aforementioned halo lighting (whereby light reflected from behind a sign illuminates its silhouette).

While neon and fluorescent lighting are still fairly commonly used around the world today and can serve their purpose effectively for many years, LEDs have proven a strong alternative for the illumination of channel letters, lightboxes and other backlit signage applications. Indeed, they may well signal the eventual demise of the older lighting technologies.

LEDs offer an array of benefits for illuminating signs, including reliability, ease of installation and energy savings. Even HB LEDs are low-voltage and can be operated with low running costs, making signs both brilliantly bright and energy-efficient. LEDs also offer increased longevity over traditional forms of lighting, reducing maintenance costs over the life of a sign.

“LED lighting offers several improvements for outdoor signage lighting compared with standard fluorescents,” says Mark Shephard, global product manager for General Electric (GE) Lighting, “from significant energy cost reductions and easier job-site installation to less frequent maintenance and more consistent brightness to better uniformity and cold weather performance.”

Metal or acrylic sign letters can be front- or rear-illuminated with LEDs or halo-illuminated for a more subtle, esthetically pleasing effect. LEDs can also be used to edge-light acrylic panels, which can be installed independently as ‘light sheets,’ connected as ‘light walls’ or integrated into aluminum frames to serve as ultra-thin lightboxes.

Traditional aluminum lightboxes have been effective for decades and remain very popular today, as they are as simple in design and construction as their name suggests; i.e. a box is illuminated from within. When fabricated in the traditional manner, however, lightboxes consume excessive quantities of energy. A typical large-format lightbox may measure 6 x 3 m (20 x 10 ft), for example, and will require 45 58-W fluorescent tubes for effective illumination. Even if it is operated for only 12 hours a day, it will consume approximately 12,000 kW of electricity per year, for an annual electricity bill in excess of $1,000.

[2]

[2]In April 2914, Churchill Downs – known for the annual Kentucky Derby – unveiled the ‘Big Board’ which is named the world’s largest 4K LED-based video board by the Guinness World Records. Photos and figures courtesy ElectroniCast Consultants.

Another problematic issue for traditional aluminum signs is maintenance. If just one fluorescent tube is faulty, the sign will present its graphics poorly. And with 45 or more tubes in a single sign, the likelihood of such a fault, at any given time, is rather high. Flickering and/or broken tubes can quickly represent significant ongoing costs in terms of sign maintenance.

The flexibility and ease of installing LEDs makes them ideal for the on-site retrofitting of existing illumination systems for channel letters, lightboxes and backlit signs. There is often no need to remove or replace the sign.

In terms of flexibility, with a bending radius of less than 1.3 mm (0.05 in.) and a life cycle of more than 500,000 bends, LEDs can be installed at practically any angle, following the tightest channel contours, all in one continuous strip and using only one or two connectors per letter.

With power consumption averaging only 0.8 W per linear foot, LEDs are indeed a very efficient lighting system, allowing two or three average channel-based signs to use the same amount of electricity as a single 100-W incandescent light bulb. And with the addition of a photovoltaic system to collect and store solar energy, some signs can even be illuminated independently without a direct connection to any traditional power source.

It is notable that specific LEDs have been developed especially for channel letters, lightboxes and backlit signage applications. Ultra-high-intensity semiconductor chips are uniquely packaged to ensure uniform illumination with a wide light-emitting angle. As a result, most 203-mm (8-in.) stroke channel letters can be illuminated using single rows of LEDs, without creating visible ‘hot spots’ (i.e. areas brighter than others), in depths as low as 63.5 mm (2.5 in.).

Many new LED systems have been designed as replacement kits for upgrading fluorescent-illuminated sign boxes and cabinets, providing anywhere from 58 to 76 per cent energy savings over T12 high-output (HO) fluorescent lamps. They are available in a wide variety of sizes and colour temperatures, offering the versatility necessary for signmakers to improve the overall esthetics of a multitude of single- and double-sided sign sizes and styles. Some can use existing fluorescent lamp sockets for quick installation, reducing labour time and costs.

Another factor is optics. Lens technology has been configured to help ensure light is emitted as efficiently as possible, while also protecting the LEDs themselves against moisture, humidity, damage and corrosion.

Fluorescent lamps emit light in a 360-degree pattern. With LEDs, on the other hand, each module is shaped to capture otherwise wasted light and redirect it where it is needed, i.e. toward the surface of the sign. Optics are key in eliminating the striping and shadows on the sign face that can occur with fluorescent tubes.

[3]

[3]Guinness also named ‘Big Hoss TV’ at Texas Motor Speedway the world’s largest HDTV screen.

Digital signage

While many ongoing analyses of LEDs have focused on their potential to displace traditional lighting systems in the sign industry and mainstream architectural applications, this can lead to misconceptions about their true value propositions, which need to be overcome. Many applications of LEDs are indeed intended to replace existing fixtures, but others are serving as new models for ‘digital light,’ exploiting ways to control light dynamically to provide information. Hence, LEDs have become highly useful in the digital signage sector.

In April 2014, Churchill Downs—the thoroughbred racetrack in Louisville, Ky., that is famous for hosting the annual Kentucky Derby—unveiled an enormous video screen built by Panasonic Enterprise Solutions. Designed to provide a clear viewing experience for everyone at the venue, including thousands of fans throughout the (26-acre) infield, the screen measures 52.1 m (171 ft) wide and 27.4 m (90 ft) tall—framing an active display area of 1,414 m2 (15,224 sf)—and sits 24.4 m (80 ft) above the ground, offering a wide viewing angle. It is positioned midway along the backstretch and outside the dirt course to avoid becoming a distraction to the jockeys and horses.

Construction of the ‘Big Board’ started in December 2013 and was completed in March 2014, in plenty of time for the Spring Meet, the Kentucky Oaks and the 140th running of the Kentucky Derby. Digging deep enough to bury 12 steel support beams into 13.7 m (45 ft) of bedrock solved local installation challenges posed by an underground river. Weighing 544 t (600 tons), the structure was built to withstand wind speeds up to 145 km/h (90 mph).

The Big Board is designed to display more than nine million lines of resolution. This gives its operators an array of creative content capabilities, ranging from replays, image close-ups, betting odds and race results to advertising, recorded programming and multiple split-screen views.

It may come as no surprise that the Big Board for Churchill Downs was named the world’s largest ‘4K’ LED-based video board by the Guinness World Records. Incidentally, a few weeks earlier, a Guinness adjudicator also officially certified Panasonic’s ‘Big Hoss TV’ screen at Texas Motor Speedway in Fort Worth, Texas, the largest LED-based high-definition (HD) TV screen in the world. Measuring 66.4 x 28.7 m (218 x 94 ft), it offers an active display area of 1,917 m2 (20,633 sf), incorporating 4.8 million pixels and capable of generating 21 trillion different colours. The 98-t (108-ton) structure rests on 16 support beams, each buried 12.2 m (40 ft) deep into bedrock.

“Sports and entertainment represent a growing business market for digital signage, including HD LED boards,” says Jim Doyle, president of Panasonic Enterprise Solutions. “This offers an excellent opportunity to deliver customized video systems.”

In the out-of-home (OOH) advertising industry, meanwhile, LED-based digital billboards—sometimes referred to as electronic billboards—are providing a more effective medium than traditional boards for marketers to reach an audience with timely and relevant messaging. For billboard operators, meanwhile, they increase revenue potential by increasing the number of messages and advertisers each location can feature. Hence, the benefits for all parties are clear.

Advertising clients in this respect can include both local and national businesses, as they may book ongoing campaigns or short-term promotions, given the dynamic nature of the medium. They can tailor their campaigns to deliver the right message to the right audience at the right time. Copy can be changed in the midst of a campaign, to better align brand communications in response to consumer trends.

CBS Outdoor Canada, for example, allows advertisers to book its digital billboards by ‘daypart’ to take advantage of different traffic patterns at different times in different cities (including Edmonton, Calgary, Regina, Saskatoon, Toronto, Ottawa and Montreal). The company encourages clients to use multiple designs to deliver creative messages and keep the public interested in their campaigns. The medium has proven an ideal complement to traditional OOH promotions, to say nothing of repurposing creative elements from online, TV or print campaigns.

For the public, too, digital billboards offer new benefits. They enable the real-time delivery of emergency notifications, for example, such as Amber Alerts, along with other announcements for travellers and/or local communities.

Typically, digital billboards update their displayed content every four to 10 seconds, often depending on local regulations. For similar reasons, most do not feature animation, flashing lights, scrolling or full-motion video, but rather switch between static images. And while these images are brighter than printed billboard graphics, they must also often meet standards that restrict their brightness levels.

As with traditional billboards, digital billboards are typically located ‘off-premise’—i.e. not on a specific business’ property to promote its own brand, but some distance away, often along a road where it will be most highly visible to traffic and/or pedestrians. The operators can then sell space on the digital billboard to a variety of third-party advertisers.

An on-premise LED sign, on the other hand, would also be located outdoors but within the premises of a given business. Smaller than a billboard and typically mounted on the building, as a monument sign or mounted on a set of posts, this type of display is used by the business owner or organization to exclusively promote its specific brand and offerings directly to the public. It is more common for these on-premise, LED-based digital signs to be allowed to feature animation, scrolling images and full-motion video, but again it depends on local zoning regulations.

Stephen Montgomery is president of ElectroniCast Consultants, which forecasts trends in LED illumination and communication networks. For more information, visit www.electronicast.com.

- [Image]: https://signmedia.ca/testhm/wp-content/uploads/2014/12/Dundus_Square.png

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/12/FIGURE-5_ElectroniCast.png

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/12/Panasonic_TexasMotorSpeedway.png

Source URL: https://www.signmedia.ca/ongoing-developments-for-leds-in-signs-and-displays/