Precision printing with the right tools

Now that the COVID-19 pandemic is behind us, companies of all sizes are looking for a marketing refresh, and many are turning to print shop providers (PSPs) for solutions. In addition to new logos and interior and exterior rebranding efforts, many fleet graphics owners are coming in for a new or renewed look. Shop owners such as Jason Carolla of Studio Graphics in Ville St. Laurent, Que., are primed to take advantage of this surge.

Carolla and his print production manager and right-hand man, Andrew Ford, tell us how Studio Graphics got started, how they grew the business, and why their production environment includes the latest latex ink technology.

Ginny Mumm (GM): How did you decide to start Studio Graphics?

Jason Carolla (JC): Back in 2001, I discovered I wouldn’t be inheriting my father’s clothing importation company, as he had decided to shut it down. I had worked at his company for six years, developed a good base in sales, and I learned to use Adobe Illustrator and Photoshop along the way.

I picked up the phone book and started cold-calling businesses to sell them business card design and printing. Soon after, I purchased a Roland DG GX-24 cutter and started to make coroplast signs.

One day, I had a client who was taking over a transport company. I hired a freelance designer and paid him to create a new logo. Once I had a logo, I knew the client would like, I set it up on Adobe Illustrator with a fresh-looking trailer design.

I landed the contract to remove all the company’s old graphics, cut and install 150 units of 16.4-m (53-ft) trailers, and install 65 tractors. That’s how Studio Graphics was born. Once we completed that job, we landed other transport industry contracts.

GM: Is your shop still in its original location?

JC: We launched in 2001 from my basement. In 2014, I rented my first 167.2-m2 (1,800-sf) location. In 2023, we moved to our current location, which is 278.7 m2 (3,000 sf).

Our office is in a commercial condominium complex centrally located in Ville St. Laurent, Montreal’s commercial and industrial sector. Our facility has a temperature and humidity-controlled print room, two offices, and a reception area. Although we are not set up as a retail location, we do have the occasional walk-in client.

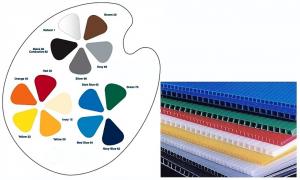

Our front office has a Pantone Light booth, so we can accurately match colours. When we moved in, we upgraded all our lighting to 5000K daylight LED lighting for more accurate colour viewing. Our warehouse is 204.3 m2 (2,200 sf), and all our tables are on wheels, so we can expand our installation bay when needed and increase our production space when no vehicles are in the bay.

GM: What specialties did you have starting out, and have you changed your product mix since then?

JC: We stopped doing 53-ft trailers, as these days, there is too much competition driving down the prices. We also do almost no colour change vehicle personalization jobs as they take more space, resources, and time than commercial work or fleet graphics.

GM: How many employees do you have?

JC: We currently have five employees and multiple installation contractors. We believe the key to our success is each individual’s contribution.

Andrew Ford joined Studio Graphics as a designer approximately 10 years ago. Today, every Studio Graphics project touches his desk. Andrew’s skills and abilities, along with his understanding of the business and willingness to get things done, have been critical to our success.

Rashaun Mapp Gittens was our production specialist until 2022 and is now living in Toronto working part-time for us as an installer. This past year, he took the 3M VIT and AIT installer training courses to refine his installation skills. John Milchem was hired as our production specialist during the height of the pandemic. John is fully versed in Adobe Photoshop and Illustrator, print production, and sign and graphics installation. Vincent Turchetta is our production and installation assistant and the newest addition to our team.

Jean Sebastian Leduc is our vehicle graphics installation specialist. His attention to detail ensures precise application of every graphic, and his speed minimizes downtime for our clients. Jean Sebastian’s expertise and efficiency make him an invaluable asset to our team.

GM: How did you select your production equipment?

JC: I learned early on in my career that if you want to have quality results, invest in the tools. I always buy the best tools for the job.

My first machine was the Roland DG GX-24 cutter. Shortly after, I purchased a used printer/cutter from an authorized dealer. I had the machine for more than five years and sold it for only $4,000 less than I paid. The machine was a tank and never broke down. I realized the return on investment (ROI) was high. I kept investing in these devices because of the low cost of ownership, high reliability, and high-quality output.

GM: What equipment do you have in your shop today?

JC: We moved the GX-24 cutter to Toronto for Rashaun to use, but within our shop we are running a Roland DG TrueVIS AP 640 latex printer, GR2-640 cutter, GS2-24 cutter, and an eco-solvent Roland DG printer/cutter.

GM: Why did you decide to invest in a latex ink printer? Which features were most attractive to you?

JC: The colour gamut and the dry time of the latex/resin ink were the first eye-openers. At first, we were a little skeptical about making the switch over to resin ink. In the past couple of years, I’ve looked at some of the other latex machines on the market. I deal with a large network of shops across North America, and the consensus from them was that there was a tradeoff of quality when you make the switch to latex with regard to vehicle wraps.

Nick Bathurst from Pony Graphics did a fantastic job of addressing our concerns. Nick supplied us with output samples on the printable wrap material of our choice. During my stretch testing and installation, I couldn’t find a significant difference between the eco-solvent printed wrap film and the sample Roland AP-640 latex printed film. Nick also supplied us with a print sample of one of our client’s red brand colour. The printed colour was significantly outside anything we could replicate on our older devices. The red was vibrant, saturated, and brighter than we could print before.

With an increased colour gamut compared to the older generation machines, we can easily achieve deeper, richer, more saturated, band-free solid colours. This is impressive, especially considering that the resin ink is water-based.

GM: What types of applications are you printing on your latex printer?

JC: We’ve printed various items for numerous applications, ranging from small stickers for local companies to large murals for business and commercial spaces. We’ve also created large graphics for events such as game launches. We’ve done fleet graphics, vehicle wraps, and trade show graphics.

Being in Montreal, every year we print and install vehicle graphics for many events with tight deadlines. One we always get jammed up for is the Formula 1 race. We get a lot of last-minute requests, so the fast dry time of our AP-640 is a big advantage—it allows us to print and laminate immediately.

GM: How has your move to latex impacted your fleet graphics production?

JC: So far, we have used latex ink to wrap a variety of vehicles, including Ford Transits, Sprinters, and other utility vans. We’ve also wrapped numerous pickup trucks, box trucks, and transport trucks. In addition, we’ve wrapped a few exotic cars. Currently, we are wrapping a Ferrari 296 for the Challenge Club Ferrari series. The production has been quick and accurate—everything we were hoping for.

Andrew Ford (AF): It’s incredible how technology has advanced. Now, I can print something, laminate it, and immediately apply it to a car. In the past, we had to wait a day or more before continuing with production, which was a significant hindrance. Today, I can schedule clients in the morning, and their job is completed by the afternoon.

GM: What is your view of the vehicle graphics market?

AF: Over the past few years, the vehicle graphics market has really taken off, with more commercial businesses using lettering, partial wraps, and full wraps for eye-catching advertising.

I’ve noticed many more partial wraps, as people are trying to be cost-effective, getting the most bang from their graphics without spending a boatload of cash. It’s impressive to see how much the demand for vehicle graphics has grown—more and more companies are looking for innovative ways to promote their brands on the go.

GM: What do you see looking forward for Studio Graphics?

JC: We continue growing our commercial vehicle wrap and retail market work. We are looking to implement colour processes in our production flow to achieve and maintain consistent, repeatable, and accurate colour across all our machines.

Our company consistently delivers high-quality work, and we are solutions-based. We have the knowledge, experience, and production equipment needed to get niche jobs done well.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.