Higher return on investment (ROI) with printing on canvas

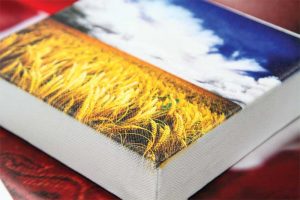

An increasing number of consumers are seeking prints on canvas as a way to display their treasured images.

These days, competition from copy shops and commercial printers has left many print shops striving to provide one-stop solutions for their clients. They already offer dozens of applications, including vehicle graphics, posters, backlit displays, and even heat transfer applications for apparel and accessories. Adding printing on canvas can be an easy and profitable way to provide additional solutions for clients while accessing an important market.

“In a print shop environment, canvas prints are almost 100 per cent custom or personalized print pieces and, therefore, tend to have a fairly high ROI,” says Valade.

Since many canvas materials are priced similarly to cast vinyl and backlit vinyl, and the cost of ink is a small portion of the overall cost, production costs for prints on canvas are generally comparable to other printed products, explains Valade. However, because most prints on canvas are high-quality, custom pieces, the selling price for canvas prints is typically higher than it is for other print products such as decals or posters.

Providers can also add value to their canvas prints by handling post-production processes such as stretching and framing in-house. Alternatively, they can choose to send that portion of the workflow to a framing or art shop.

Media mecca

With the growing popularity of canvas printing applications, media manufacturers have recognized the need to create materials suitable for each type of ink, and the number of canvas printing media options available for each type of printer—water-based, eco-solvent, and UV printers—has markedly increased in recent years.

Choosing a media finish is often a very subjective decision. This being the case, Valade recommends providing samples printed on a few different materials before printing the final product.

“Typically, for canvas printing, we see a mix of different types of matte media, which is similar to actual artist canvas,” he says. “However, satin and gloss finishes are also quite popular.”

Beyond finish, another important consideration for choosing media includes the composition of the media itself. The media’s texture is determined by the material used (e.g. cotton, polyester, etc.), the diameter of the fibres, and how tightly they are woven. These factors also impact the weight of the material. A heavier media will be easier to stretch and frame, while a lighter one, although it may not hold up as well, may be more economical. Similarly, the texture of the media can have an impact on the look of the finished product.

Fortunately, with all the media options available, there will likely be one (or more) that works for each client.

Fortunately, with all the media options available, there will likely be one (or more) that works for each client. Having a printed sample allows clients to see and feel the material, which helps avoid costly reprinting jobs.

Workflows that flow

According to Valade, printing canvas is actually one of the easier workflows. However, he emphasizes the importance of having a high-resolution design file.

“If a customer brings in a JPEG that is 102 x 102 mm (4 x 4 in.) actual size, it will be difficult to make that image look good when it’s blown up to a 609.5- x 457-mm (24- x 18-in.) canvas print,” he says.

Therefore, Valade recommends setting minimum resolution requirements to avoid having to redesign the image.

“Print shop owners can also offer pricing for the additional time needed to complete design work in-house, which will ensure they are demonstrating value to the customer at each step in the process,” he adds.

When printing on canvas, Valade tells users to select a high-quality setting and run in unidirectional print mode. He also suggests using a custom profile from the media manufacturer for the printer, if available. This takes a lot of guesswork and experimenting out of the process.