Printing on Canvas: Why print shop owners are saying “Yes” to this lucrative market

by | 18 May 2019 1:46 pm

By Ginny Mumm

[1]

[1]Adding print on canvas be an easy and profitable way to provide additional solutions for clients while accessing an important market.

As print technology improves and consumers’ understanding of what is possible in printing expands, print shop owners are increasingly asked to produce graphics and images on canvas. The market for these customized, high-margin products has grown rapidly over the past five years, and printing on canvas is taking up a bigger share of the overall online photo printing market as well.

Clients of every stripe are interested in these distinctive prints. Professional artists and photographers frequently request printing on canvas as a way to produce limited editions of their art and photography. And, increasing numbers of consumers are seeking prints on canvas as a way to display their treasured images and family photos. In addition, business clients are using stylish canvas applications to spice up interior environments. The increase in visibility provided by social media sites has also contributed to the overall rise in interest in these unique custom prints.

There are many good reasons for print shop owners to say “Yes” to requests for prints on canvas. For starters, many shops already have the technology they need to produce such prints in-house. Additionally, since many print shop owners are under pressure to provide a one-stop solution for their customers, offering prints on canvas can be a profitable way to attract and retain clients.

Versatile print technology for printing on canvas

Whether customers are looking for high-volume printing on canvas, or smaller scale production of one-off canvas prints, the easy answer to, “which type of printer is best for printing on canvas?” can often be “the printer you have in-shop.” Many of today’s wide-format inkjet printers, including aqueous, eco-solvent, and ultraviolet (UV) models, can be used to produce prints on canvas. Water-based and eco-solvent printers can print onto several types of canvas media, while UV/light-emitting diode (LED) flatbeds can print directly onto ready-made canvases as well.

According to Daniel Valade, Roland DGA’s product manager for colour printers and cutters, eco-solvent inkjets can offer a few advantages for printing on canvas applications.

“In the mid-level price points, the colour gamut of today’s eco-solvent printers tends to be larger, and there are more types of canvas materials available that are designed and coated specifically for eco-solvent devices,” says Valade.

The market for UV printers is still growing, and Jay Roberts, Roland DGA’s product manager for UV printers adds, “As the UV market matures, we are seeing a wider variety of materials that can be used for canvas prints and other types of prints.”

The advantage of using an advanced UV printer is having the ability to print on almost any substrate while achieving high-quality output. The full range of UV printers, from desktop to benchtop to large-scale UV flatbeds, can all print directly onto ready-made canvases.

Further, Roberts says many of today’s UV printers also offer gloss inks, which allow users to incorporate unique textures, patterns, brush strokes, and other artistic effects to create truly original pieces.

Regardless of which type of inkjet is used for printing on canvas, today’s ink and printer technology combine to help ensure realistic colours, smooth colour transitions, and sharp image definition.

Higher return on investment (ROI) with printing on canvas

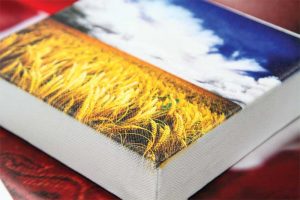

[2]

[2]An increasing number of consumers are seeking prints on canvas as a way to display their treasured images.

These days, competition from copy shops and commercial printers has left many print shops striving to provide one-stop solutions for their clients. They already offer dozens of applications, including vehicle graphics, posters, backlit displays, and even heat transfer applications for apparel and accessories. Adding printing on canvas can be an easy and profitable way to provide additional solutions for clients while accessing an important market.

“In a print shop environment, canvas prints are almost 100 per cent custom or personalized print pieces and, therefore, tend to have a fairly high ROI,” says Valade.

Since many canvas materials are priced similarly to cast vinyl and backlit vinyl, and the cost of ink is a small portion of the overall cost, production costs for prints on canvas are generally comparable to other printed products, explains Valade. However, because most prints on canvas are high-quality, custom pieces, the selling price for canvas prints is typically higher than it is for other print products such as decals or posters.

Providers can also add value to their canvas prints by handling post-production processes such as stretching and framing in-house. Alternatively, they can choose to send that portion of the workflow to a framing or art shop.

Media mecca

[3]

[3]Ultraviolet (UV)/light-emitting diode (LED) flatbeds can print directly onto ready-made canvases.

With the growing popularity of canvas printing applications, media manufacturers have recognized the need to create materials suitable for each type of ink, and the number of canvas printing media options available for each type of printer—water-based, eco-solvent, and UV printers—has markedly increased in recent years.

Choosing a media finish is often a very subjective decision. This being the case, Valade recommends providing samples printed on a few different materials before printing the final product.

“Typically, for canvas printing, we see a mix of different types of matte media, which is similar to actual artist canvas,” he says. “However, satin and gloss finishes are also quite popular.”

Beyond finish, another important consideration for choosing media includes the composition of the media itself. The media’s texture is determined by the material used (e.g. cotton, polyester, etc.), the diameter of the fibres, and how tightly they are woven. These factors also impact the weight of the material. A heavier media will be easier to stretch and frame, while a lighter one, although it may not hold up as well, may be more economical. Similarly, the texture of the media can have an impact on the look of the finished product.

Fortunately, with all the media options available, there will likely be one (or more) that works for each client.

Fortunately, with all the media options available, there will likely be one (or more) that works for each client. Having a printed sample allows clients to see and feel the material, which helps avoid costly reprinting jobs.

Workflows that flow

According to Valade, printing canvas is actually one of the easier workflows. However, he emphasizes the importance of having a high-resolution design file.

“If a customer brings in a JPEG that is 102 x 102 mm (4 x 4 in.) actual size, it will be difficult to make that image look good when it’s blown up to a 609.5- x 457-mm (24- x 18-in.) canvas print,” he says.

Therefore, Valade recommends setting minimum resolution requirements to avoid having to redesign the image.

“Print shop owners can also offer pricing for the additional time needed to complete design work in-house, which will ensure they are demonstrating value to the customer at each step in the process,” he adds.

When printing on canvas, Valade tells users to select a high-quality setting and run in unidirectional print mode. He also suggests using a custom profile from the media manufacturer for the printer, if available. This takes a lot of guesswork and experimenting out of the process.

Opening new markets

[4]

[4]Water-based and eco-solvent printers can print onto several types of canvas media.

Roberts also recommends print shop owners start by looking for canvas print media that has custom profiles for their printer and ink set.

“Profiling has become a must for media manufacturers to remain competitive,” he says. “Colour management experts dive deep into ink limits, heater settings, head speed, and feed rates. They do a lot of the leg work that print shop owners had to do for themselves several years ago.”

Offering a choice of materials with different finishes can also help clients see the difference the finish makes with their particular project.

“A customer who wants a photo printed may want a gloss finish, while a customer asking for prints of a hand-painted piece may prefer the matte artist canvas finish,” says Valade.

Stocking gloss and matte finish media as well as having samples of various weights and textures on-site can help customers make their selections more easily. Following these simple steps will allow print shop owners to accommodate their clients’ canvas printing needs, while remaining relevant and responsive to this growing trend.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Fine-art_canvas_living_room_Roland_TrueVIS_VG2-540_eco-solvent_printer-cutter.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Fine-art_canvas-framed_Roland_TrueVIS_VG2-640_eco-solvent_printer-cutter.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Canvas_print_Roland_VersaUV_LEF-300_flatbed_UV_printer.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/Roland_TrueVIS_VG2-640_eco-solvent_wide-format_printer-cutter.jpg

Source URL: https://www.signmedia.ca/printing-on-canvas-why-print-shop-owners-are-saying-yes-to-this-lucrative-market/