Profile: Kalitec

by all | 9 February 2017 10:15 am

[1]

[1]Photos courtesy Kalitec

By Peter Saunders

When Jean Lapointe (pictured) founded Kalitec in 1989 in his apartment in Laval, Que., he had a very Canadian goal in mind: to develop a street sign post that could endure harsh, snowy winters, particularly given the threat of damage by snowplows and other vehicles.

“It was a big project,” he says. “The road sign posts available at the time were manufactured in the U.S. and weren’t suitable for areas requiring snow removal. They would get broken throughout the winter.”

In the end, he accomplished his aim with a three-part sign post, dubbed Kalifix. One part was an anchor, to be installed below the ground. The second part was the above-ground post. And the key third part was a connector to join them.

“This way, if a plow were to hit the sign, only the connecting pin would break and that could be replaced inexpensively,” Lapointe explains. “We could save 90 per cent of the sign, including not only the anchor and the post, but of course the sign face, too!”

The research and development (R&D) process for the breakaway product took nearly seven years, during which Kalitec specialized in manufacturing industrial signs for large factories in the Montreal area. Today, its outdoor sign products are widely used all across Canada, from the rebuilt downtown area in Lac-Mégantic, Que., to the national park in Jasper, Alta.

Gradual growth

Having previously worked for Acme Signs and Aluminium Dufresne, Lapointe was able to differentiate Kalitec from the beginning with his combined experience, by using aluminum instead of corrugated plastic for the production of the company’s aforementioned indoor factory signs.

“No one was doing that for industrial clients,” says Lapointe. “Using aluminum allowed us to offer higher quality.”

While these signs—generally used to display procedures, rules and safety warnings—were being installed in factories, Lapointe continued to grow his sales force, to the point where it could court municipal purchasers once Kalitec’s outdoor sign products were ready. The first buyer for the Kalifix post system was the city of Trois-Rivieres, Que., which ordered a run of 50.

“Every year, I would hire one or two more people,” Lapointe says. “We didn’t sell much outside Quebec at that time. Our market mainly stretched from Ottawa to New Brunswick, with some customers in Nova Scotia, too.”

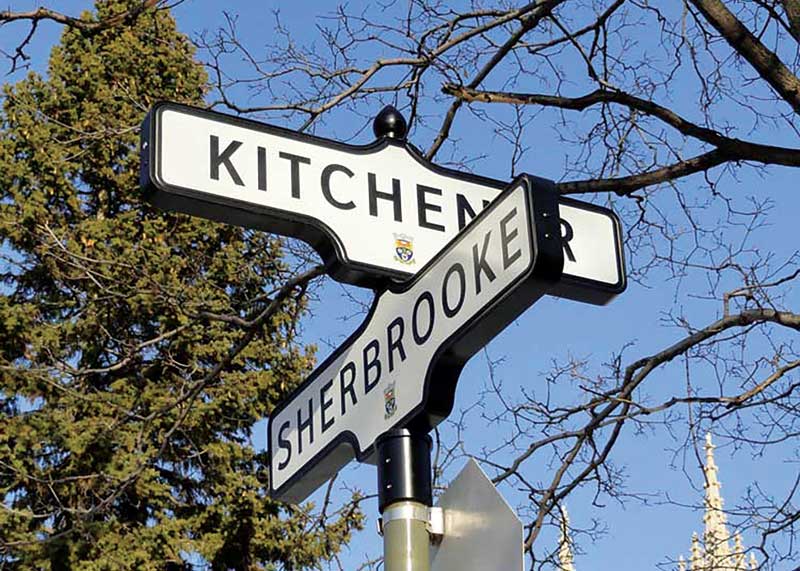

Kalitec’s street signs have been adopted in many Quebec neighbourhoods, including Westmount, a suburb of Montreal.

In 2002 and 2004, he attempted two significant efforts to expand across more of Canada and into the U.S., but neither proved particularly fruitful. So, Kalitec continued to focus primarily on its Quebec customers for the following 10 years.

Smarter signs

Finally, in 2005, a new product line began to draw wider attention. Having already served municipalities with its street signs, Kalitec made these products ‘smarter’ with the addition of light-emitting diode (LED) arrays to display dynamic messages, powered by solar batteries. Specifically, they were geared to municipal needs, serving as digital speed signs that indicate to drivers how fast they’re going.

“That made it easier to sell the breakaway post, since now it was worthwhile to more customers, being part of a more valuable sign,” Lapointe explains. “It gave our post a second life where it would be useful 365 days a year in many places, rather than only appealing to those with severe winter weather.”

Indeed, Kalitec’s ‘smart signs’ are now in use not only across Canada, but also in the U.S. and as far abroad as Melbourne, Australia, where a public transportation company has ordered 1,500 of them.

“By working with partners around the world,” says Lapointe, “my hope is we’ll be present on all five continents within the next five years.”

[2]

[2]In the first main department of Kalitec’s Laval plant, metal (primarily aluminum) is cut with a CNC router, then spot-welded.

Back to Shawinigan

As it grew, Kalitec moved into successively larger facilities in Laval in 1992 and 2001. The most major expansion came in 2015, with the addition of a second business, Aten, in Lapointe’s hometown of Shawinigan, Que.

With the current configuration, the 1,301-m2 (14,000-sf) Laval plant comprises three main departments. In the first, metal—primarily aluminum—is cut with a computer numerical control (CNC) router, bent and welded with specialized equipment. In the second department, the company uses powdercoating for in-house paint jobs. And in the third, sign graphics are produced with a mix of flatbed and roll-to-roll (RTR) inkjet printers.

The 790-m2 (8,500-sf) Aten facility in Shawinigan, meanwhile, is dedicated to storage and assembly of products aimed at the burgeoning ‘smart city’ market. Solar panels and LEDs are sourced for use in a variety of applications, including a weather-sensing sign that warns pedestrians when a sidewalk may be slippery.

“In addition to aluminum, we have dies for manufacturing plastic frames for digital signage, as a cheaper option,” Lapointe says.

Together, the facilities are staffed by a team of 40 employees.

[3]

[3]Jean Lapointe’s sons, Anthony (left) and Charles-Eméric (right), oversee sales, marketing, finance and operations.

Armoured prints

While the growing market for dynamic signage has fuelled much of Kalitec’s recent growth, the company also continues to find success in static applications. Its most recent launch, at 2016’s Sign Expo Canada, was Print Armor, a new brand for graffiti-resistant printed signs.

“The idea came from our existing municipal customers, who had long complained about graffiti on their signs,” says Lapointe. “I spent 10 years and thousands of dollars developing it. On two occasions, I wanted to quit, but my sales agent begged me not to.”

The resulting aluminum signs allow nearly all types of graffiti to be easily washed away with an alcohol solution, offering 10-year durability. Kalitec does the printing in-house, then supplies the signs to municipal governments or, alternatively, other sign shops that integrate them into larger projects, such as interpretive panel systems.

Looking long-term

Going forward, Lapointe’s role as president will continue to focus more on mid- and long-term signage R&D efforts than on short-term matters. His two sons, Charles-Eméric and Anthony, now oversee most of the company’s day-to-day activities, including sales, marketing, finance and operations.

“My biggest challenge is getting good, new products ready at the same time as the international market is ready to buy them,” he says. “There are many opportunities out there and we have to keep focused on the synergy between our products. We’re not a large company, so we really have to plan carefully for our work to be successful.”

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/kalitec_jean_logo_5poucesx8.5pouces_300_DPI_cmyk.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/kalitec_photo2-7poucesx5pouces-300dpi-CMYKK.jpg

- [Image]: https://www.signmedia.ca/?attachment_id=31528

Source URL: https://www.signmedia.ca/profile-kalitec/