Building a client base

Building a client base

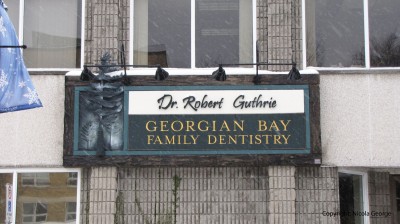

As a result of this research, in 2004, Zimmer-Zschogner became the first signmaker in her region to use HDU sign foam—and the only one to also specialize in the traditional application of 23-kt gold leaf.

“The area I was living in needed a lot of sign facelifts,” she says. “I started Wildrose Designs and obtained contracts with nearby towns. While it was hard to sell at first and this was another male-dominated industry, at least it was a type of work I could do on my own. I just had to prove myself by focusing on quality and customer service. It was exhausting at first, getting people’s approval, but once I had a bunch of successful projects under my belt, it became easier.”

Emphasizing long-lasting and water-resistant materials, she also began working with polyvinyl chloride (PVC), ultraviolet-resistant (UV-resistant) clearcoats, laminated steel, fibreglass and manufacturer-warrantied channel letters. The riveting and aircraft modification skills she had acquired at an early age in her father’s airport hangars gave her confidence using power tools.

“My clients’ specific interest in signage depends on the area,” she says. “Cottagers like the hand-carved dimensional elements, for example, while professionals operating businesses in Northern Ontario recognize durable building-identification signage as an investment that makes their locations look more permanent. Townships commission ‘Welcome to …’ signs and I’ve also done work for schools.”

Another factor affecting the signmaking process is the local climate. While Alberta’s air tends to be dry, Ontario’s is often humid, requiring coated signs to be dried for much longer before use.

“As mentioned, quality and customer service are my top priorities, but sometimes timelines throw a monkey wrench into the works,” she says. “I remember one day when we had multiple clogged spray guns, hazardous materials (hazmat) spills on sign supply trucks and transportation issues. Every problem has a solution, but I won’t rush a job. And my clients tend to appreciate it’s worth the wait.”

Working with others

Working with others

In 2009, Zimmer-Zschogner was awarded a contract to design, fabricate and install signage and wayfinding components at Canada’s only J.W. Marriott Hotel and Resort, located on Ontario’s Lake Rosseau. It was a big job, emphasizing the need for a co-operative effort.

“It took my team three months to develop a 200-page wayfinding, signage and branding guide,” she says, “with designs for 220 interior bronze signs, resort trail signs, maps, interpretive signs and traffic signs, requiring the approval of two local townships.”

Indeed, Zimmer-Zschogner is not alone in her efforts. With a history going back to woodcarvers in Germany’s Black Forest and relatives who have built everything from clocks to furniture, her family includes painters, carpenters and welders who have worked in and near Parry Sound for more than 20 years, many of whom now help her build signs.

“I’m the project manager,” she explains. “While I specialize in hand-carving dimensional signs with a chisel and applying gold leaf, the work I do by myself depends on the job. I’m allergic to chemicals and laminates used in some processes, for example, so I leave those up to a professional crew led by my cousin, Ray Reschke, who owns Northern Lights Painting and Decorating.”

Another reason to call upon others’ help is the large scale of some projects.