Reading the fine print

by carly_mchugh | 1 December 2022 4:54 pm

[1]

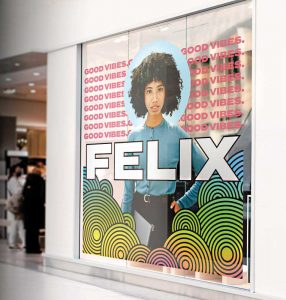

[1]Innovations in printer technology, inks, and software have enabled print service providers (PSPs) to keep up with today’s growing market demands. Photos courtesy Roland DGA

By Ginny Mumm

Along with the rest of the Canadian economy, the digital printing industry has experienced its share of turbulence this year. Between supply chain slowdowns and currency fluctuations, print service providers (PSPs) have had to be nimble and prepared for possible material and equipment delays. Still, demand for digital printing remains strong. In fact, according to Marketsandmarkets.com, the size of the global digital printing market is expected to grow from US$24.8 billion (C$31 billion) in 2021 to US$34.3 billion (C$44.2 billion) by 2026, at a compound annual growth rate (CAGR) of 6.7 per cent. The report credits “growing demand for sustainable printing and developments in packaging and textile industries” as key factors driving the market’s growth.1

Innovations in printer technology, inks, and software have enabled PSPs to address today’s market demands head-on, including the continuing rise of e-commerce and the macro trend towards personalization and customization. To further explore the industry’s growth, we spoke with Roland DGA product managers Daniel Valade, Jay Roberts, and Kitt Jones, as well as regional sales manager Don Ross, for insight on the Canadian digital printing market.

Revving up colour production

What are some of the wide-format printing trends you have seen?

Daniel Valade (DV): We definitely foresee a continuation of the personalization and customization trend through 2022 and beyond. This trend has fostered the development of additional robust, reliable, and affordable desktop printers and printer/cutters for providers looking to enter the market. These devices enable users to produce T-shirts, posters, stickers, and decal graphics from home or a smaller office.

As the pandemic winds down and trade shows slowly return, manufacturers of wide-format equipment have continued to develop additional ways to communicate with clients. Using social media channels, road shows, and special events, companies are working to provide users with valuable product updates, tips, and insights for maximizing business growth, productivity, and profitability.

[2]

[2]Newer, expanded colour gamuts for eco-solvent printers allow users to easily achieve previously challenging hues.

How are newer ink formulations contributing to the advancement of colour printing?

DV: Today’s expanded colour gamuts and inkset options provide vibrancy and smooth colour transitions which make printed output more accurate than ever. Specialized inks offer new options for orange and green which, when paired with the latest software, allow users to reach new areas of colour including purples, reds, greens, and other previously challenging hues.

Are there any new software developments for colour product printers?

DV: Software is also undergoing rapid transformation as companies introduce apps which allow users to remotely monitor their printer operations. The development of automation software for easier and faster production is among the other leading trends we are seeing.

What new directions do you see for colour printing overall heading into 2023?

DV: We expect the push for superior colour output to continue, with manufacturers developing software, hardware, and ink options to simplify workflows and enhance colour management. We are also seeing increasing sales interest as print shops emerge from the uncertainty of the last few years.

[3]

[3]The newest colour printers are designed to improve production power, automate functions, and expand colour options.

Growing demand for customization

What are some of the ultraviolet (UV) market trends you have seen? Why are so many shops adding UV print capability?

Jay Roberts (JR): In addition to offering PSPs expanded production capability for a range of applications, UV printers can address the customization and personalization requests shops are increasingly receiving for an ever-widening range of products. With UV print, shops can add graphics to a variety of media and 3D products in ways which help these items maintain a marketing purpose—either promoting a brand or concept or adding personalized touches.

Consumer research has shown printed customization increases a product’s perceived value, allowing shops to profit from offering this service. Along with colour, graphic, or typographic enhancement, a UV printer’s gloss and white specialty inks can produce unique dimensional and textural effects which add pop and style to any customized print.

Tell us about the UV ink options available today. How are these options advancing UV printing overall?

JR: Manufacturers have created a range of low volatile organic compound (VOC) UV ink options to suit a variety of needs. Expanded colour gamut inksets offer red and orange inks which make colour management across platforms easier than ever. There are also versatile, affordable ink options on the market which offer excellent adhesion, vibrant colour, and outstanding durability, in addition to meeting strict safety standards.

What has changed in terms of software for UV print?

JR: UV printer manufacturers have been developing software which enhances the print experience in terms of functionality and overall ease of use, as well as improving output. For example, recently released software allows specific machines to print up to 8 mm (0.3 in.) away from an object’s surface. This is especially helpful when printing on uneven objects or surfaces, such as golf balls. Additional software improvements across the industry have made colour management and machine operation easier than ever.

What are some of the UV printer technology trends you have seen?

JR: With increasing depth tolerances and innovative configurations, today’s UV inkjet printers can print precise, professional, full-colour graphics directly onto a wide array of substrates and objects.

What do you see ahead for this market in 2023?

JR: With recent innovations in printer technology, along with recent advances in software and inks, demand for UV printers will continue to be strong in the Canadian market. Not only do UV printers offer a versatile solution, but they are also easier to use, easier to assemble, and more mechanically reliable than ever before.

[4]

[4]New, hybrid ultraviolet (UV) printers allow users to print on flexible media as well as thicker printable substrates.

Evolving flexibility of DTG production

What trends have you seen in the textile/direct-to-garment (DTG) market?

Kitt Jones (KJ): With the rapid rise of e-commerce, we have seen an explosion in demand for custom-printed apparel. As a result, the market’s supply of custom printed T-shirts has grown, leaving shops fighting with a plethora of competitors over pennies of profit—and there is only so much you can charge for a shirt.

Manufacturers have responded with innovative large-format DTG printers, which offer users the flexibility to print on a wide variety of apparel and textile products. Today, we are seeing many shops looking to move “beyond the T-shirt,” diversifying their product lines to offer less common and higher-margin items like personalized towels, jackets, and jeans.

What do some of the newer DTG printers provide in terms of features?

KJ: The newest DTG printers offer users improved speeds, higher-quality print, and lower production costs. Beyond overall enhancements like these, it is important to consider the additional capabilities of newer large-format DTG printers. Production capacity is another key feature when considering printing technology. A high-production DTG printer can print as much as three standard DTG printers, while only requiring one operator.

How is today’s software making DTG more accessible?

KJ: Software is a key element in DTG, and it is really where the momentum is right now. Raster image processor (RIP) software is processing data faster, adding automation, and controlling inks better, which allows different types of printing by managing the white under base more effectively. In addition, user interfaces are being simplified to automate workflows, to make operating small- and large-format DTG printers easier than ever.

What new directions do you see for the DTG market heading into 2023?

KJ: I think the roadmap for growth in DTG is positive. I see the market moving towards personalization and customization of a wider variety of fabric and apparel products. Certain machines allow users to print on larger and smaller products—everything from T-shirts to sleeping bags. A Z axis clearance of up to 203.2 mm (8 in.) allows users print on diverse products such as decor and accessories, as well as apparel.

Analyzing Canada’s digital print market

How is the Canadian market doing overall?

Don Ross (DR): As we move beyond the pandemic shutdown, the Canadian market is slowly rebounding. It has not yet recovered its previous momentum, due in part to the current exchange rate with the U.S. dollar. Further, conferences and other events are returning at a cautious pace.

Are supply chain delays continuing to impact the digital printing market?

DR: Pandemic-related supply chain issues have certainly hurt print providers, and vendors who have been less impacted by the supply chain have benefited. Fortunately, we are seeing a gradual easing of these supply chain issues.

[5]

[5]The ability to print on items like tote bags, towels, and napkins gives PSPs new options for customizing products.

Which types of digital printing devices are seeing growth in Canada?

DR: Of the various types of digital print devices, the Canadian market for UV print devices has shown continued growth, and I expect this growth will continue into 2023.

Moving forward

Overall, the market for digital print continues to expand. However, market factors such as exchange rates and supply chain concerns may hinder the ability for PSPs to respond quickly. Advances in print technology, inks, and software mean today’s digital print devices can print on an even wider range of products and substrates, meeting the market’s demands for rapidly produced and customized products, while remaining easy to operate and maintain.

Notes

1 For more information, visit https://www.marketsandmarkets.com/Market-Reports/digital-printing-market-97124440.html.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2022/12/Roland-DG-Texart-XT-640S-DTG-Printer.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2022/12/Vehicle_wrap_semi_trailer_Roland-DG_TrueVIS_VG3_Series_printer-cutter.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2022/12/Retail_Window_sign_Roland_DG_TrueVIS_VG3-640_printer-cutter.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2022/12/Roland-DG-VersaUV-LEC2-S-Series-Belt-driven-hybrid-UV-printer.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2022/12/DTG_accessories_Roland_DG_Texart_XT-640S.jpg

Source URL: https://www.signmedia.ca/reading-fine-print/