Refining the design

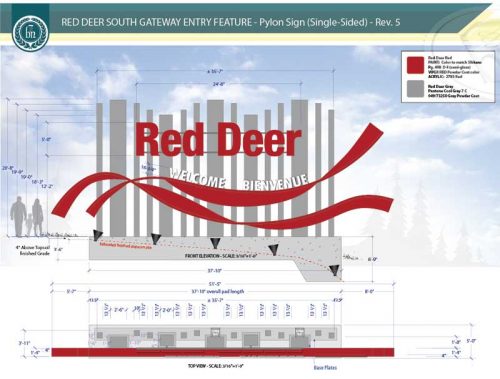

Blanchett Neon’s coloured interpretation of the signage intent, which notes the orientation of the individual columns and the location of the power.

With more than 70 years of experience in the design, permitting, fabrication, and installation of municipal entrance signage, Blanchett Neon knew the importance of honouring the original design intent provided by Stantec, while balancing the city brand standards, fabrication and permitting requirements, and ensuring the work could be completed at the cost presented—not to mention finishing the project within the extremely tight timeline.

After being awarded the contract, meetings were immediately arranged with Stantec and the city project managers to refine the original concepts into construction-ready drawings.

The first step was to recreate the provided drawings in the company’s preferred design software, Adobe Illustrator, followed by a second set of scaled AutoCAD drawings to share with the various suppliers and partners.

One of the design considerations included the mounting detail for the illuminated ‘Red Deer’ letters and the ‘ribbon’ to the steel pillars. Initially, the plan was to protrude knife blades from the pillars for mounting the signage elements, but ultimately, the team arrived at the decision to incorporate a raceway (painted to match the powder-coated steel), due to the ease of installation and wiring the letters and using knife blades for mounting the ribbon only.

The sign’s 15 steel pillars presented the next challenge—not to mention a number of questions about their overall intent (Were they hollow? Were they structural?) to how they would be transported from Edmonton to Red Deer (approximately 154 km [95.5 miles]), along with the orientation and mounting for each unique column.

Given the height of the individual poles (ranging from 5.3 m [17.5 ft] to 5.9 m [19.5 ft]), powder-coated hollow structural sections (HSS), complete with individual anchors for each column in the concrete pad, were found to be the most economical solution.

The ‘Elk’ design was also scrutinized to ensure that (given the size) it could be transported without the need for specialized equipment. To get around this obstacle, the drafting team (along with support from Blanchett Neon’s steel partner) was able to have the structure designed in three smaller, easily transported pieces, with fasteners hidden in curves of the display.

Once it was confirmed with Stantec and city officials that the final design met their expectations, Alberta Transportation (AT) was contacted to determine what was required

to approve the signage (as the installation locations fell under its jurisdiction). In this case, it included achieving stamped engineered drawings, and using a formal surveyor to ensure displays were placed accurately outside the highway right of way.

Project co-ordination

When bidding on the job it was recognized the City of Red Deer was looking for a turnkey solution and that specific elements (including running conduit for power, concrete, and landscaping) fell outside of Blanchett Neon’s in-house capabilities. Therefore, the team knew it would need to lean upon its extensive partner network.

After being awarded the contract from the City of Red Deer, the company almost immediately reached out to its partners to ensure they recognized the urgency of the project and could meet the firm completion deadline.

Starting with engineering, extensive conversations took place between Stantec and Blanchett Neon’s engineer to ensure the newly constructed hillside (from completion of the intersection) met stability specifications and the new concrete signage foundations would not be affected by improper compaction as the ground continued to settle over time.

Once the drawings had been stamped, the land surveyors (as required by AT) used global positioning system (GPS) technology to ensure the exact orientation and distance from the roadway was maintained to formally stake the installation sites for review and approval by Stantec and the city.

An ongoing challenge throughout the process was unimpeded access to the worksite. With the other construction in the area still underway, Blanchett Neon was required to maintain the flow of traffic along the busy corridor and no complete road closures were permitted. To mitigate the risk to passersby and to protect crews working on-site, a formal traffic accommodation plan was created. Extensive safety measures were also taken including the use of a flagger, signage, and barricades for the duration of the project.

In addition to the firm project timeline, winter conditions were also a factor as they would present a different set of challenges

and completing the concrete foundations (including excavating the frozen ground) was no exception. Custom forms (more than 0.30 m [1 ft] thick) were constructed on-site, and polymer additives—along with site heating and hoarding—ensured the concrete cured properly despite an average daytime temperature of -20 C (-4 F).

While the concrete was being completed by one partner, the sign installation team worked with the city to determine the placement of the new transformer that would feed the light-emitting diode (LED) fixtures for the illuminated displays, and how to tie power into existing services (avoiding other underground utilities in the process). Keeping the site access restrictions in mind, the team’s solution was

to trench power approximately 300 m (984 ft) directly to the gateway display, and then directionally drill the power beneath the access road to the ‘Elk’ (another 100 m [328 ft]) to service the displays.