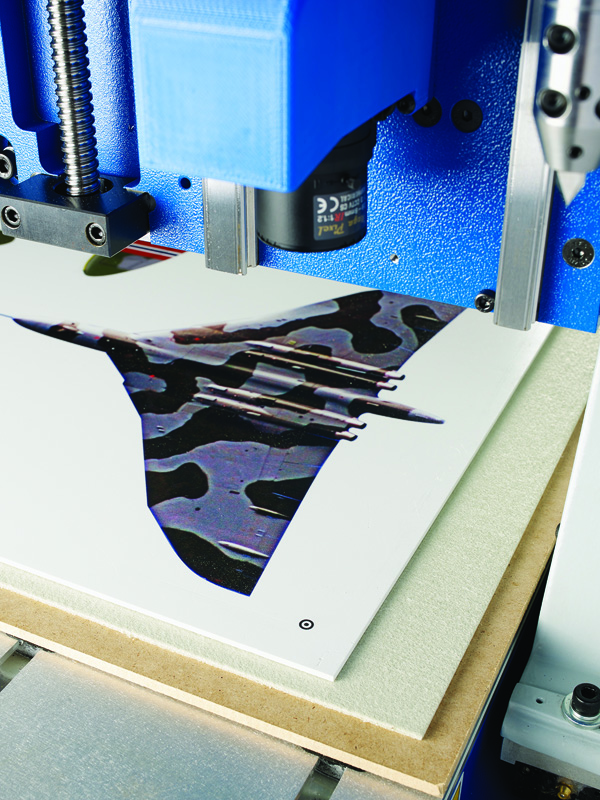

Routers: Choosing a CNC hybrid machine

Other considerations

There are also a number of other issues to consider in terms of taking the ‘long view’ before investing in CNC hybrid technology.

One of these is, of course, the sign shop’s inkjet printer, which will help determine what size of cutting table the CNC router should have. If the printer is capable of outputting 1.8-m (6-ft) wide graphics, for example, then a 1.2-m (4-ft) wide hybrid router is probably not the right choice. That would introduce an unnecessary limitation and potentially drive clients’ business elsewhere, i.e. to shops with the capabilities for accurately cutting larger signs and graphics.

Another issue is a router’s control system—how operator-friendly is it and how much training is needed? If the principal operator is ever sick at home or away on vacation, after all, then backup personnel will need to be able to step in, with only a minimum of disruption and downtime.

The aforementioned benefit of versatility is also variable. The CNC hybrid machine’s capabilities should match the sign shop’s requirements as closely as possible, whether for longer runs where four to five pieces are the same or for custom ‘one-off’ projects. And it may well need to cut six or more different types of materials in the course of any given day.

Software can help minimize setup time for these various materials, which is a prime consideration for novices. No one wants to have to turn work away because the setup routine for a new project would cause an inordinate amount of downtime in the production schedule.

It is also important to make sure the cutting software is compatible with the sign shop’s existing graphic printing software. Otherwise, a new capital purchase could end up compounding problems, rather than fixing them and reducing labour costs and lead times for in-house jobs.

Finally, as mentioned earlier, the supplier’s level of support needs to be evaluated before going ahead with the purchase. If a problem arises, it should be easy to reach someone who can perform diagnostic services remotely, rather than wait for them to arrive on-site, so as to resolve issues quickly.

That said, support should not become a ‘crutch’ for an unreliable machine. Some CNC hybrid models can operate problem-free for months on end, while others seem to require constant maintenance. It is a good idea to do the homework and check reviews from experienced users.