Clamping down on lamps

Clamping down on lamps

UV light wavelengths are shorter than those of visible light. So, people cannot see UV radiation, including that emitted by UV lamps for curing inks and coatings.

These lamps’ radiation can be harmful, however, causing serious skin and eye damage, similar to that caused by sunlight. In the eyes, for example, UV light is known to cause or hasten cataracts associated with the aging process. As the lens of an eye absorbs UV light, it becomes cloudy, leading to vision loss.

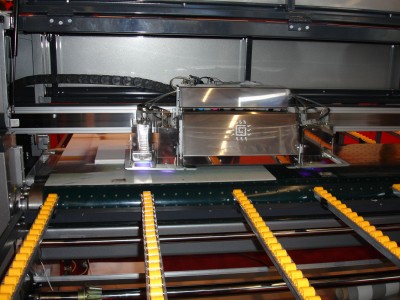

Printing equipment that uses the lamps should be properly shielded, so operators are not exposed to any UV radiation. This means using protective hoods or other housings that either are interlocked or require a tool to open them. Also, once the housing is opened, the UV lamp should automatically reduce to a harmless level of radiation.

If protective shields are opened or have been removed and the equipment is run, the operator is not only putting him or herself at risk, but also endangering co-workers in the area. So, the operator should not raise the hood to check how the print looks, but should instead wait until the substrate has cleared the UV lamps before viewing it.

In some direct-to-screen applications, screenprinted images must be exposed to UV light. Workers should either stay away during the exposure or wear UV-rated safety glasses with side shields. And their co-workers should not be allowed to pass by or through the area while the UV lamps are on.

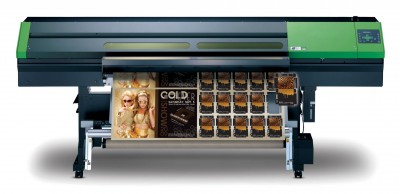

Some UV-curing printers are now using light-emitting diodes (LEDs) or light-emitting capacitors (LECs) instead of traditional, higher-energy lamps.

Further, UV lamps contain mercury vapour, a colourless, odourless, toxic gas. Exposure can affect the nervous system and kidneys.

So, when replacing UV lamps, it is important to wear gloves specifically designed for mercury exposure. In Canada, the old lamps must be disposed of as hazardous waste.

If a UV lamp is broken, it should be cleaned up with extreme caution, wearing protective clothing and shoe coverings. Instead of vacuuming or sweeping the spill, the glass pieces and powder should be scooped up carefully with pieces of cardboard, then placed into a plastic container. Once this container is sealed with duct tape and labelled as mercury waste, it should be placed with all cleanup supplies in an outer plastic bag. Finally, this bag should also be sealed and labelled as mercury waste for collection by a waste hauler.

As mentioned, UV lamps create heat and ozone, the odour of which can irritate the mucous membranes of the eyes, nose and throat. To control this ozone, the lamps are fitted with exhaust systems to discharge air outside the building. Ozone is very unstable and will quickly change back to oxygen, but it is important to check exhaust systems are working properly.

Change for the better

UV-based printing has led to many positive changes in today’s sign shops. There are no airborne solvents from the inks and coatings, energy costs are lower as heaters are not needed for drying, so there is a reduced risk of fires or explosions; and printing times are faster, with immediate curing.

While these changes are beneficial, there are still health risks. Knowing these risks, following good work practices and using PPE, printer operators can enjoy the benefits while staying safe.

Marcia Y. Kinter is vice-president (VP) of government and business information for the Specialty Graphic Imaging Association (SGIA). For more information, visit www.sgia.org.