Safety with UV-curable materials

by Matthew | 10 September 2012 8:30 am

[1]

[1]File photos

By Marcia Y. Kinter

Many professionals in the sign industry work with ultraviolet-curable (UV-curable) inks and coatings in wide-format printing processes, but may not know or think about the associated health and safety risks. It is important to take certain precautions, not only with UV-curable materials, but also with the UV lamps used to cure them.

Ink ingredients

All inks contain both pigments to provide colour and resins to ensure they are flexible and can adhere to substrates. They also contain other additives to help them perform effectively.

In solvent-based ink systems, for example, the solvent acts as a carrier for all of the other ink ingredients and provides the proper viscosity. Once the solvent carries the ink to the substrate, it is no longer needed and evaporates.

In UV-curing systems, on the other hand, solvents are replaced by monomers. These are chemicals with a very simple molecular structure. Monomers can combine to form polymers.

UV-curable inks and coatings also contain photoinitiators. As soon as they reach the substrate, they are exposed to light from a UV lamp. The photointiators then begin a chain reaction of bonding between the monomers and the resin. This process continues until all of the molecules are cross-linked and polymerized, at which point the ink is fully cured, becoming a dry solid.

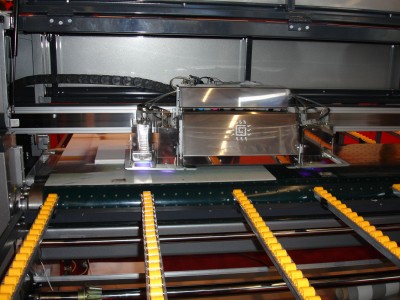

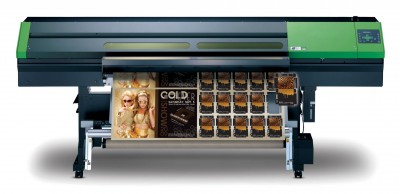

[2]

[2]UV-curable inks are commonly used in both screenprinting (above) and digital printing systems (right).

Health hazards

Many printing professionals are already aware of the hazards associated with solvent-based inks, including dry, irritated skin and respiratory irritation. Further, some solvents are carcinogenic.

While UV-curable materials do not contain conventional solvents and have no chronic, long-term health effects, they can still pose acute hazards. Before they are cured, they can slightly or severely irritate the skin and eyes.

The skin irritation is the same condition that results from touching poison ivy or poison oak, causing a red, itchy, weepy reaction at the point of contact. For some people, this reaction happens within an hour or two. For others, it can take up to two days to show up.

If skin contacts UV materials, it should be washed immediately with mild soap and cool to tepid water for 15 minutes. Solvents should never be used to wash skin.

It is best not to wear jewellery at work, but any worn during contact with UV materials should be taken off while washing, to ensure no contaminants remain trapped underneath. Similarly, any clothing and shoes contaminated with the materials must be removed, as they will otherwise continue to contact the skin, eventually causing a reaction. Contaminated clothing should not be cleaned at home with other, non-contaminated clothes.

If a UV-curable material comes into contact with the eyes, they should be washed at an emergency station and flushed with cool to tepid running water for 15 minutes. Contact lenses, if worn, should be removed immediately, as they can trap contaminants against the eyes. And if any irritation or ‘gritty’ feeling remains after flushing, it is worth visiting a doctor.

[3]

[3]Before they are cured, the inks can cause irritation to the skin and eyes.

Preventing problems

Personal protective equipment (PPE) and good work practices can minimize direct skin and eye contact with UV-curable materials to keep signmakers safe and healthy.

Safety glasses

When mixing or pouring UV-curable materials, there is a chance of ink splashing back into the eyes. Whenever this risk exists, it is important to wear safety glasses.

In screenprinting shops, for example, glasses should be worn whenever working on the underside of a screen or press, as ink could drip or splash toward the eyes. The same is true when pouring inks into bulk delivery systems for inkjet printers.

Protective gloves and clothing

Protective gloves and clothing should be worn based on the tasks at hand. In screenprinting, for example, when mixing or pouring ink, carrying it to the press or cleaning the screens and squeegees, there can be direct contact with UV-curable materials. The same is true in digital printing when emptying waste ink reservoirs, cleaning printheads and setting up machines.

Nitrile or neoprene gloves that are impervious to these materials are recommended to eliminate the chance of contact with the hands, along with a nitrile or neoprene apron when mixing inks. Long sleeves and pants should fit closely to the body, to protect against direct contact without risking getting caught in equipment. Gloves and clothing containing latex should be avoided, as many people are allergic to it.

Some technicians wear flashspun high-density polyethylene fibre arm gauntlets and coveralls when they carry ink cans to presses, protecting their arms and legs in case any UV-curable materials rub off. This clothing is also recommended for workers who empty trash bins containing substrates with wet (i.e. uncured) UV materials.

Some people like to use ‘barrier creams,’ which form a protective layer between the skin and outside contaminants. These should be used in conjunction with protective gloves and clothing, never by themselves.

[4]

[4]In screenprinting, it is important to wear protective gloves and clothing when cleaning the screens and squeegees, as there could be direct contact with UV-curable materials.

Safety glasses, gloves and protective clothing are needed when cleaning up a spill of uncured UV materials—along with protective shoe coverings, if the cleaning necessitates stepping into the spill. Any objects contaminated by the spill should be placed in a bag or container, so no one else comes into contact with them, either.

Respiratory protection

UV materials have a distinctive odour, even at room temperature, but this odour by itself does not indicate a hazard. Since there is no solvent, there is no evaporation, so the components of ink do not become airborne.

During printing, for example, a strong odour will be noticed when the photoinitiator is hit with UV light and begins the curing process. This odour is not hazardous, though some people find it unpleasant. Most of it should be sent away from the substrate through an exhaust system, along with the ozone and heat from the UV lamp.

No respiratory protection is required when using these materials, but if their odour becomes bothersome, it may be worth checking the exhaust system on the press.

Disposal considerations

As is the case with all inks, waste UV materials should never be disposed of down the drain. They should be collected and then managed off-site by a licensed waste handler, keeping them separate from solvent inks, cleaning solvents and other waste.

Other practices

In combination with PPE, good work practices to protect against exposure to UV materials include the following:

- Keeping work areas tidy, clean and free of all traces of UV materials.

- Keeping all surfaces wiped clean, since UV materials left upon them will not evaporate or cure over time.

- Storing contaminated shop towels in closed bins, not on the press or in a pocket.

- Washing hands after every task where they are exposed to UV materials, even when gloved.

- Never eating or drinking near UV materials.

[5]Clamping down on lamps

[5]Clamping down on lamps

UV light wavelengths are shorter than those of visible light. So, people cannot see UV radiation, including that emitted by UV lamps for curing inks and coatings.

These lamps’ radiation can be harmful, however, causing serious skin and eye damage, similar to that caused by sunlight. In the eyes, for example, UV light is known to cause or hasten cataracts associated with the aging process. As the lens of an eye absorbs UV light, it becomes cloudy, leading to vision loss.

Printing equipment that uses the lamps should be properly shielded, so operators are not exposed to any UV radiation. This means using protective hoods or other housings that either are interlocked or require a tool to open them. Also, once the housing is opened, the UV lamp should automatically reduce to a harmless level of radiation.

If protective shields are opened or have been removed and the equipment is run, the operator is not only putting him or herself at risk, but also endangering co-workers in the area. So, the operator should not raise the hood to check how the print looks, but should instead wait until the substrate has cleared the UV lamps before viewing it.

In some direct-to-screen applications, screenprinted images must be exposed to UV light. Workers should either stay away during the exposure or wear UV-rated safety glasses with side shields. And their co-workers should not be allowed to pass by or through the area while the UV lamps are on.

[6]

[6]Some UV-curing printers are now using light-emitting diodes (LEDs) or light-emitting capacitors (LECs) instead of traditional, higher-energy lamps.

Further, UV lamps contain mercury vapour, a colourless, odourless, toxic gas. Exposure can affect the nervous system and kidneys.

So, when replacing UV lamps, it is important to wear gloves specifically designed for mercury exposure. In Canada, the old lamps must be disposed of as hazardous waste.

If a UV lamp is broken, it should be cleaned up with extreme caution, wearing protective clothing and shoe coverings. Instead of vacuuming or sweeping the spill, the glass pieces and powder should be scooped up carefully with pieces of cardboard, then placed into a plastic container. Once this container is sealed with duct tape and labelled as mercury waste, it should be placed with all cleanup supplies in an outer plastic bag. Finally, this bag should also be sealed and labelled as mercury waste for collection by a waste hauler.

As mentioned, UV lamps create heat and ozone, the odour of which can irritate the mucous membranes of the eyes, nose and throat. To control this ozone, the lamps are fitted with exhaust systems to discharge air outside the building. Ozone is very unstable and will quickly change back to oxygen, but it is important to check exhaust systems are working properly.

Change for the better

UV-based printing has led to many positive changes in today’s sign shops. There are no airborne solvents from the inks and coatings, energy costs are lower as heaters are not needed for drying, so there is a reduced risk of fires or explosions; and printing times are faster, with immediate curing.

While these changes are beneficial, there are still health risks. Knowing these risks, following good work practices and using PPE, printer operators can enjoy the benefits while staying safe.

Marcia Y. Kinter is vice-president (VP) of government and business information for the Specialty Graphic Imaging Association (SGIA). For more information, visit www.sgia.org[7].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/picture_03.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/piture_04.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/anapurnamw.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/election4.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/SunLLCUVLEDEvolutionInkjetprinter-2_edited-1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/VersaUV-LEC-540-2.jpg

- www.sgia.org: http://www.sgia.org

Source URL: https://www.signmedia.ca/safety-with-uv-curable-materials/