Selecting the best substrate for your signage

Luster board

Luster board is another solid candidate for both indoor and outdoor signage projects. It is particularly great for long-term outdoor projects due to its light weight and durability, which justifies the cost and provides the most value for the sign maker. Like aluminum composite material, luster board consists of multi-layered bonded panel. However, the core is made up of several layers of pressed hardwood and high-end plywood, and the aluminum surfaces are factory finished with a polyester coating. The finish on the aluminum panels makes luster board great for graphics detail and high impact colour statement.

Some signage applications of luster board include billboards, real estate signs, company signs, and multi-piece art installments.

Others

There are several other substrate options available depending on the project it is being used for. Specialty textured materials should be considered for creative projects, while foamcore is a cost-effective substrate for short-term indoor use. Metal composites or wood can also be considered for appropriate signage projects.

Factors to consider

Some things to consider when picking a substrate include cost, lifespan, maintenance, repairs and replacements, and external factors.

Often, the higher the quality of the substrate, the higher the cost. As a result, signmakers need to find a good balance between choosing the best substrate for a particular project and the solution that makes the project most profitable

When starting a signage project, one of the most important questions to ask a client is, “How long do you want this signage to last?” Clients typically respond with, “As long as possible.” However, not every sign needs to last very long depending on the occasion. For example, political signs are often used for a short period of time, hence the time frame should be factored into the life span of the product, and, ultimately, the signage adopted for such project.

Maintenance, repairs, and replacement is also an important factor to consider before selecting a signage substrate because the substrate may suffer damage, regardless of how durable it is. Signmakers should forecast the potential damage each substrate is prone to and account for how to fix such signs when damages occur.

Another important factor in picking a substrate is exposure to external factors such as sunlight and extreme weather. Over time, continuous exposure to such factors affects how the signage ages. As a result, sign makers should factor in how long the signage should be out for and which substrate is most suitable for such conditions.

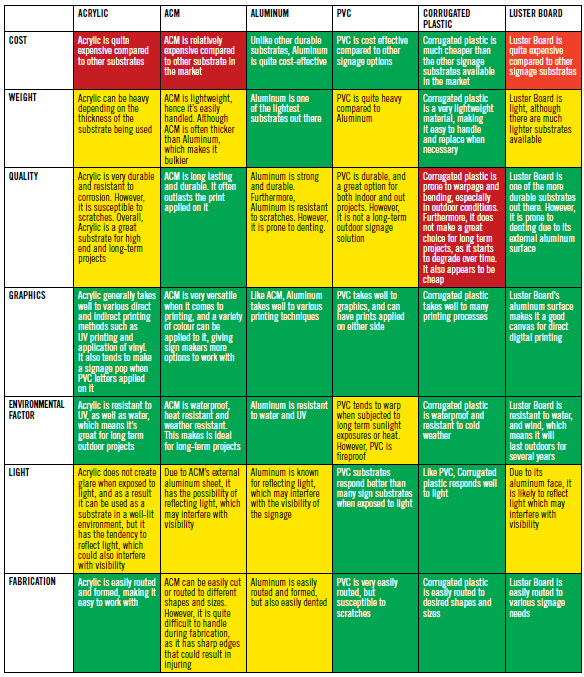

The colour-coded table below shows the strengths and weaknesses of each substrate, and serves as a guide in comparing the substrates discussed above.

References

(http://www.madehow.com/Volume-2/Acrylic-Plastic.html)

(https://www.acplasticsinc.com/informationcenter/r/acrylic-vs-polycarbonate)

(https://signsforsuccess.biz/products/rigid-signs/materials-and-substrates/).

(https://www.thesignbros.com/blog/business-owners-guide-sign-materials-substrates/)

(https://signsforsuccess.biz/products/rigid-signs/materials-and-substrates/)

(https://www.printmoz.com/blog/sintra-board-vs-foam-board)

(https://www.bossprintstore.com/product/luster)

Fola Kunle-Hassan is a design engineer at DNS Industries, dedicated to producing innovative store fixtures and display solutions for a store experience that showcases their clients’ brands. With a background in mechanical engineering and computing technology, Fola has developed practical experience over the years in the design and manufacturing of store fixtures and display solutions. DNS Industries can be reached by email at sales@dnsdisplay.com.