Selecting the best substrate for your signage

by courtney_bachar | 24 March 2022 3:23 pm

Sintra on acrylic. Photos courtesy DNS Industries

By Fola Kunle-Hassan

Signs are a vital part of many successful businesses. They draw attention to a place of business, as well as market goods and services to the public. In designing a sign, the best sign companies will ensure the product meets its objectives while respecting the project budget.

As many signmakers already know, achieving the ideal sign requires picking out the best size, shape, colour scheme, and placement, among other considerations. However, the most important factor is realizing the best signs come from deciding which substrate to use for a particular project. This article will act as a guide for selecting the right substrate to get the most out of a signing project by outlining the pros and cons of different substrates, and some of the best applications for each type.

Acrylic

A top candidate for signage substrates due to its very versatile and durable nature, acrylic is made from methyl methacrylate monomer, which is commonly sold under the brand names of Plexiglas, Lucite, Perspex, and Crystallite. Acrylic is a tough, highly transparent material with excellent resistance to ultraviolet radiation and weathering. It can be transparent or coloured, formed, and easily routed to custom shapes and parts. These properties make acrylic a substrate that can be used for both indoor and outdoor signage projects and can last up to five years outside and over a decade inside. Acrylic signs are often mounted on walls with aluminum standoffs.

Acrylic can be directly printed on, or vinyl can be applied on it as well. One very common technique is to have polyvinyl chloride (PVC) cutouts applied on acrylic, which gives a good contrast and makes the sign stand out. It is relatively rigid and comes in a variety of thicknesses from 1.5 mm (1/16 in.) to 25 mm (1 in.).

Another reason acrylic is such a versatile substrate is that instead of it being used as the base material, it can also be used as clear cover, giving signs a fine finish. Acrylic applications include modern lobby displays, backlit signs of all types, and 3D lettering.

PVC panel being prepared for a signage project.

Aluminum composite material (ACM)

Aluminum composite material is another versatile and durable substrate used for both indoor and outdoor signage projects. ACM is a multi-layered bonded panel consisting of a polyethylene core sandwiched between two thin sheets of pre-finished aluminum. Due to polyethylene’s lightweight and structural properties, ACM is a great substrate that is easily routed to custom shapes and dimensions. When it comes to projects that call for adventurous designs, ACM is one of the top contenders. Graphics can be painted on digitally or screenprinted on and, in other cases, vinyl can be applied onto ACM panels. It is an excellent material for indoor or outdoor applications that require good dimensional stability, low weight, and a sleek, brilliant look.

ACM metal panels are both attractive and practical for use in visual merchandising, framing, archiving, commercial interiors and exteriors, construction, and fine art applications. Adventurous designs demand ACM for its esthetic qualities combined with rigidity and ease of fabrication.

Aluminum

Aluminum is another great long-term option for signage substrates, and one of the most popular options out there. Although aluminum could be used for indoor signage projects, its true potential is realized outdoors. Aluminum is durable and versatile and can be used for simple panels as well as complex sign projects. It is often combined with acrylic for products such as channel letters.

Aluminum is commonly available in .04-gauge thickness, which is used for real estate signs, .08-gauge, which is used for street signs and road signs, and.125-gauge, which is used for heavy-duty sign applications.

Although aluminum is already resistant to rust and oxidation, it is quite common to find aluminum substrates galvanized to give a textured appearance for a product with a more unique finish. This makes aluminum a great option for household decorations, outdoor signs like directional signage and parking signs, as well as store fronts and lobby signs.

Polyvinyl chloride (PVC)

PVC is a great option for short to medium-term indoor and outdoor projects. PVC is made from moderately expanded closed-cell polyvinyl chloride in a homogenous sheet. Due to its light weight and durability, PVC is the go-to substrate for sign makers creating signage for advertising, photo-mounting, screenprinting, and other general outdoor signs. PVC is also resistant to scratches, cuts, and dents, which means it could be left outside for fairly long periods without any major impact on its condition or quality. PVC substrates are great for flatbed printing, allowing for a variety of designs. Vinyl application is another common way to transfer graphics onto PVC substrates.

Some of the brand names for PVC include Foamacell, Kapabloc, and Sintra. PVC is an excellent choice for menu boards, tradeshow signs, yard signs, point of sale displays (POS), among other applications. It is also an excellent choice for wall signs indoors.

Corrugated plastic

Corrugated plastic is a great substrate for short-term outdoor signage projects, and an excellent candidate for long-term indoor signage projects. Corrugated plastic consists of three layers of polypropylene, an internal honeycomb-shaped or beam-shaped layer sandwiched between two thin-walled external layers.

Corrugate is a particularly great substrate for graphics purposes as it takes well to various printing processes and is often a great canvas, especially with a white surface, that adds a pop when colours or prints are applied. Graphics can be made by vinyl application or directly with flatbed printing, allowing for a variety in designs options. Due to its surface properties, corrugated plastic holds on to the applied colour for a long period of time, even with exposure to sunlight. Corrugated plastic is very versatile when it comes to installation, as it can be hung from walls or ceilings and is easily attached to posts.

Some of the brand names include Coroplast, Corex, and Coro. Some applications in which corrugated plastic is typically used include menu boards, special event signs, yard signs, directional signs, real estate signs, promotion signs, election signs, and tradeshow signs.

CNC Machining of aluminum panel

Luster board

Luster board is another solid candidate for both indoor and outdoor signage projects. It is particularly great for long-term outdoor projects due to its light weight and durability, which justifies the cost and provides the most value for the sign maker. Like aluminum composite material, luster board consists of multi-layered bonded panel. However, the core is made up of several layers of pressed hardwood and high-end plywood, and the aluminum surfaces are factory finished with a polyester coating. The finish on the aluminum panels makes luster board great for graphics detail and high impact colour statement.

Some signage applications of luster board include billboards, real estate signs, company signs, and multi-piece art installments.

Others

There are several other substrate options available depending on the project it is being used for. Specialty textured materials should be considered for creative projects, while foamcore is a cost-effective substrate for short-term indoor use. Metal composites or wood can also be considered for appropriate signage projects.

Factors to consider

Some things to consider when picking a substrate include cost, lifespan, maintenance, repairs and replacements, and external factors.

Often, the higher the quality of the substrate, the higher the cost. As a result, signmakers need to find a good balance between choosing the best substrate for a particular project and the solution that makes the project most profitable

When starting a signage project, one of the most important questions to ask a client is, “How long do you want this signage to last?” Clients typically respond with, “As long as possible.” However, not every sign needs to last very long depending on the occasion. For example, political signs are often used for a short period of time, hence the time frame should be factored into the life span of the product, and, ultimately, the signage adopted for such project.

Maintenance, repairs, and replacement is also an important factor to consider before selecting a signage substrate because the substrate may suffer damage, regardless of how durable it is. Signmakers should forecast the potential damage each substrate is prone to and account for how to fix such signs when damages occur.

Another important factor in picking a substrate is exposure to external factors such as sunlight and extreme weather. Over time, continuous exposure to such factors affects how the signage ages. As a result, sign makers should factor in how long the signage should be out for and which substrate is most suitable for such conditions.

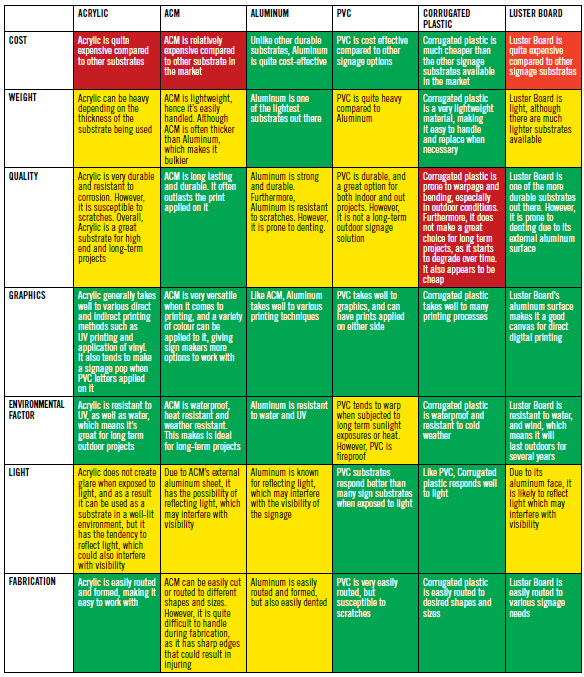

The colour-coded table below shows the strengths and weaknesses of each substrate, and serves as a guide in comparing the substrates discussed above.

References

(http://www.madehow.com/Volume-2/Acrylic-Plastic.html[1])

(https://www.acplasticsinc.com/informationcenter/r/acrylic-vs-polycarbonate[2])

(U.S. Plastic Corp[3])

(https://signsforsuccess.biz/products/rigid-signs/materials-and-substrates/[4]).

(https://www.thesignbros.com/blog/business-owners-guide-sign-materials-substrates/[5])

(https://signsforsuccess.biz/products/rigid-signs/materials-and-substrates/[4])

(https://www.printmoz.com/blog/sintra-board-vs-foam-board[6])

(https://www.bossprintstore.com/product/luster[7])

Fola Kunle-Hassan is a design engineer at DNS Industries, dedicated to producing innovative store fixtures and display solutions for a store experience that showcases their clients’ brands. With a background in mechanical engineering and computing technology, Fola has developed practical experience over the years in the design and manufacturing of store fixtures and display solutions. DNS Industries can be reached by email at sales@dnsdisplay.com.

- http://www.madehow.com/Volume-2/Acrylic-Plastic.html: http://www.madehow.com/Volume-2/Acrylic-Plastic.html

- https://www.acplasticsinc.com/informationcenter/r/acrylic-vs-polycarbonate: https://www.acplasticsinc.com/informationcenter/r/acrylic-vs-polycarbonate

- U.S. Plastic Corp: http://www.usplastic.com/knowledgebase/article.aspx?contentkey=884

- https://signsforsuccess.biz/products/rigid-signs/materials-and-substrates/: https://signsforsuccess.biz/products/rigid-signs/materials-and-substrates/

- https://www.thesignbros.com/blog/business-owners-guide-sign-materials-substrates/: https://www.thesignbros.com/blog/business-owners-guide-sign-materials-substrates/

- https://www.printmoz.com/blog/sintra-board-vs-foam-board: https://www.printmoz.com/blog/sintra-board-vs-foam-board

- https://www.bossprintstore.com/product/luster: https://www.bossprintstore.com/product/luster

Source URL: https://www.signmedia.ca/selecting-the-best-substrate-for-your-signage/