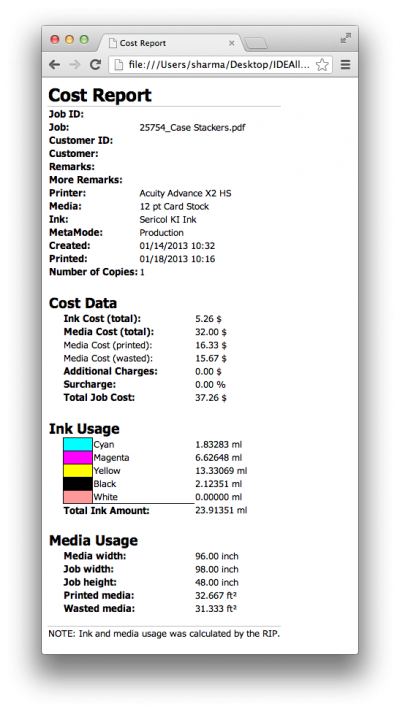

One way to monitor ink use is a software-based reporting system, which can even generate cost reports for specific jobs.

Uniformity

Another concern with larger printers is the ability to reproduce a tint evenly across an entire sheet, without unwanted colour variations or banding (i.e. areas heavier in ink).

Banding may be caused by inkjet printheads or, in the case of matte/gloss banding, by the passage of the graphics under the lamps in an ultraviolet-curing (UV-curing) printer.

Fortunately, there is already a test to ensure uniformity of tint across the sheet, which results in an M-Score rating between zero (i.e. failure) and 100 (perfect). Generally, an M-Score of 50 is acceptable, but between 80 and 90 suggests very smooth, blemish-free prints. (It is important to note corrugated substrates, due to their ribbed structure, reduce M-Scores significantly.)

In IDEAlliance and Ryerson’s independent testing, many systems scored in the range of 70 to 80.

Registration

In Ryerson’s testing, samples of cyan, magenta, yellow and key/black (CMYK) crop marks were examined under a microscope. Each mark measured 3 x 3 mm (118 x 118 mils) and was used to check ink registration between the CMYK channels. Some of the inkjet systems’ spraying of ink droplets resulted in misregistration—and in certain cases the problem only affected one colour channel.

Most signage is intended to be viewed from a sufficiently far distance and these small degrees of misregistration are not likely to be noticed. Also, when printing on non-paper substrates like polystyrene (PS) and corrugated plastic, some misregistration may be inevitable.

Nevertheless, registration is important for small features of large graphics, especially text, and is a useful way to verify a printing device is depositing various inks directly on top of each other.

RIP integration

Today’s RIPs include integration and job reporting features that are increasingly valuable in a graphic production environment, as they allow users to monitor their devices, collect ink-use metrics and identify busy periods and bottlenecks, based on the numbers of jobs—or total area—printed in each day, week and month. This information can even be reported directly to the production manager’s smart phone.

Further, today’s RIPs provide page layout and colour control, but the next generation of features will include seamless integration with web-to-print online portals, the ability to accept and process variable data, links for cloud-based systems, communications via Job Definition Format (JDF) and Job Messaging Format (JMF) and, of course, tools to measure ink consumption and Delta E colour accuracy.

In Ryerson’s testing, tiny crop marks were examined to check ink registration between the CMYK channels.

An inkjet roundup

Following the preliminary study, IDEAlliance and Ryerson are launching their first Inkjet Roundup, which extends and formalizes the test parameters.

As the process continues, IDEAlliance will provide a set of images and instructions to participating inkjet press suppliers, who will then print samples and send them back to Ryerson and CalyPoly for measurement and data collection. The data will then be published and reported to the industry as further metrics are defined and standardized.

Abhay Sharma is a professor and former chair at Ryerson University’s School of Graphic Communications Management (GCM) in Toronto. For more information, contact him via e-mail at sharma@ryerson.ca. To participate in the inkjet roundup program, contact Joe Fazzi, vice-president (VP) of media production technologies for IDEAlliance, via e-mail at jfazzi@idealliance.org.