Setting standards for colour accuracy and ink consumption

by all | 24 September 2013 8:30 am

[1]

[1]Photo courtesy Océ Display Graphics Systems

By Abhay Sharma

Wide-format digital inkjet printers are a new replacement technology for older, analogue screenprinting. There has been a strong pattern of market demand, adoption and implementation of both flatbed and roll-to-roll models, and the technology is already being used for all mainstream signage applications, such as point-of-purchase (POP) displays. As yet, however, there are no accepted standards for reporting metrics for these devices with respect to colour management and ink consumption.

Given the ubiquity of inkjet printing today, there is an urgent need to establish baseline metrics for ink use, colour accuracy and repeatability, rub resistance, weathering and uniformity across a printed sheet. Inks themselves represent a significant proportion of the costs of printing large banners and posters. In a competitive industry with tight margins, it is certainly relevant to consider parameters for determining how much ink is being used to print a particular image and how accurate the colours are in the resulting graphic.

The International Digital Enterprise Alliance (IDEAlliance), a not-for-profit trade organization that certifies digital presses for meeting or exceeding industry-established tolerances, is conducting research in conjunction with Ryerson University’s School of Graphic Communications Management (GCM) in Toronto into testing the various qualities of wide-format inkjet printing.

IDEAlliance is already well-known for publishing the General Requirements for Applications in Commercial Offset Lithography (GRACoL) and the Specifications for Web Offset Publications (SWOP) and providing the G7 system for colour calibration. The organization offers GRACoL/SWOP certification for inkjet proofing systems and digital press certification for xerographic devices. Now, IDEAlliance is turning its attention to wide- to grand-format inkjet systems by conducting the new technical tests with Ryerson.

“Such third-party independent testing is greatly appreciated, as there is a real lack of good information of this sort in the market,” says Jeff Edwards, international product marketing manager for Océ Display Graphics Systems, which manufactures wide-format printers in Richmond, B.C.

Some of these tests were conducted as part of a feasibility study earlier this year, whereby 17 different wide-format inkjet systems were tested. The process has helped inform a new formal testing procedure that Ryerson and IDEAlliance are set to launch this summer. They are also working with California Polytechnic State University (CalPoly) on this project.

Standards and metrics

To understand the need for metrics, it is worth considering common examples like the automotive industry, which has established methods for determining a car’s fuel efficiency in terms of miles per gallon or kilometres per litre, along with safety ratings and other measurements. These metrics help both the consumer, who can better select the right vehicle, and the manufacturer, who can fairly rate the vehicle against the competition.

For wide-format printing, on the other hand, no universally accepted methodology exists for measuring ink consumption, colour accuracy or other metrics.

A new document focusing on large-format printing for the sign industry—International Organization for Standardization (ISO) 15311, Graphic Technology – Requirements for printed matter utilizing digital printing technologies for the commercial and industrial production—is currently being developed. It is still in its draft phase, but when finalized, it will provide an important set of standards and metrics for determining reasonable expectations for inkjet systems.

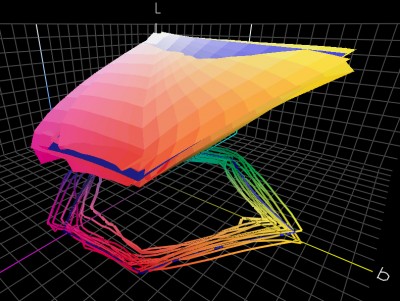

[2]Colour gamut

[2]Colour gamut

In the preliminary testing phase, Ryerson and IDEAlliance evaluated the colour gamut of 17 wide-format inkjet systems using the American National Standards Institute’s (ANSI’s) standard IT8.7/4 target for colour communications and control specifications. Each device was used to print this target image with 1,617 colour patches to help determine the colour gamut of the whole system, from printer and raster image processor (RIP) to substrate and ink.

IDEAlliance sent each test sheet to Ryerson’s labs, where data was collected to create an International Color Consortium (ICC) profile. From those profiles, each device’s International Commission on Illumination (CIE) L*a*b gamut was compared to GRACoL.

In the image on the right, where the blue area is the GRACoL gamut—i.e. representing commercial offset lithographic printing—it is clear some of the 17 inkjet devices’ gamuts were larger than that of offset printing, while many were smaller. Only three of the systems demonstrated a truly excellent colour gamut.

Colour management

One convenient way to check colour management systems are working correctly is to use a control strip with 54 patches and then measure the results with a spectrophotometer. IDEAlliance used this method for the wide-format inkjet printer testing and compared the measured CIE L*a*b values to the GRACoL target values. In other words, print samples were compared to their intended appearance.

‘Delta E’ is the CIE metric for the difference between two colours. The lower the number, the closer the two colours, meaning the colour is printed as expected, matching the sample or proof that was supplied.

The preliminary testing demonstrated that many of the wide-format systems achieved a Delta E of less than four. Some were even less than two, which put them in the realm of certified colour-accurate proofing systems.

Earlier this year, it is worth mentioning, at the International Sign Association’s (ISA’s) International Sign Expo in Las Vegas, Nev., colour management software was demonstrated with print standard verifiers, which can be used to confirm a print’s conformity to any chosen data set, such as GRACoL, SWOP or the standards established by Fogra, a German research institute for the graphic arts.

This automatic testing procedure can verify a printer’s colour management system is working as intended, which in turn implies the ICC profiles accurately reflect the colour characteristics of the printing system. In other words, IDEAlliance and Ryerson’s recent testing could now be carried out by users themselves.

[3]

[3]Ryerson University’s 2013 pilot program with IDEAlliance has evaluated a variety of wide-format digital printers, such as Océ Display Graphics Systems’ Arizona 480 GT ultraviolet-curing (UV-curing) flatbed press.

It may also be important to check colour management systems to prove to customers their graphics are being printed to specified colour tolerances. This type of verification is a way for a sign shop to explain it has the appropriate ICC profiles and can apply them within a system to print colours accurately, in accordance with the chosen data set. Besides GRACoL, there could be other standards the signmaker wants to match, such as an in-house standard or a customer-specific colour setting.

Ink consumption

Quantifying the ink consumption of a wide-format inkjet printer is very complex, as inks are used in many different ways. Ink purging and maintenance practices, for example, help keep the nozzles open and flowing freely during printing.

Some ink may spray or mist, as well, and be lost due to evaporation. And ink may be moved from its cartridge or pouch into an on-board reservoir for future use. So, ink is consumed in many ways that do not involve printing it onto a substrate.

Further complicating matters, some printers use ink sets that include cyan, light cyan, magenta and light magenta, while others use greyscale variable drop sizes. Each of these systems, then, entails a different metric for ink consumption.

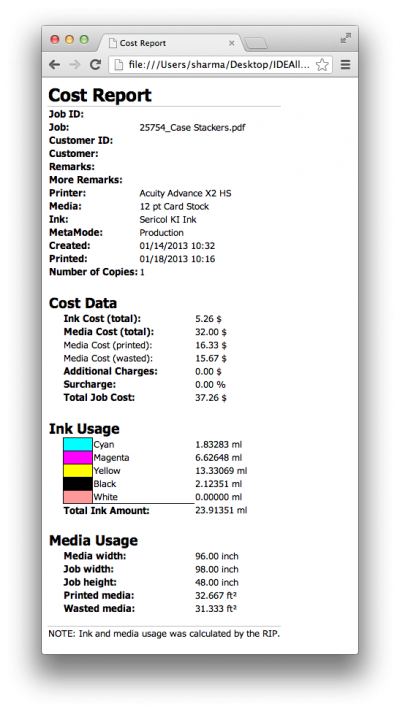

One way to monitor ink use, however, is to add a software-based reporting system. This type of technology was also showcased earlier this year at ISA’s expo, including G7 calibration, profiling and ink consumption tools that work together to evaluate a printer’s colour quality and performance. The software can even display the cost of the ink used in a given job.

[4]

[4]One way to monitor ink use is a software-based reporting system, which can even generate cost reports for specific jobs.

Uniformity

Another concern with larger printers is the ability to reproduce a tint evenly across an entire sheet, without unwanted colour variations or banding (i.e. areas heavier in ink).

Banding may be caused by inkjet printheads or, in the case of matte/gloss banding, by the passage of the graphics under the lamps in an ultraviolet-curing (UV-curing) printer.

Fortunately, there is already a test to ensure uniformity of tint across the sheet, which results in an M-Score rating between zero (i.e. failure) and 100 (perfect). Generally, an M-Score of 50 is acceptable, but between 80 and 90 suggests very smooth, blemish-free prints. (It is important to note corrugated substrates, due to their ribbed structure, reduce M-Scores significantly.)

In IDEAlliance and Ryerson’s independent testing, many systems scored in the range of 70 to 80.

Registration

In Ryerson’s testing, samples of cyan, magenta, yellow and key/black (CMYK) crop marks were examined under a microscope. Each mark measured 3 x 3 mm (118 x 118 mils) and was used to check ink registration between the CMYK channels. Some of the inkjet systems’ spraying of ink droplets resulted in misregistration—and in certain cases the problem only affected one colour channel.

Most signage is intended to be viewed from a sufficiently far distance and these small degrees of misregistration are not likely to be noticed. Also, when printing on non-paper substrates like polystyrene (PS) and corrugated plastic, some misregistration may be inevitable.

Nevertheless, registration is important for small features of large graphics, especially text, and is a useful way to verify a printing device is depositing various inks directly on top of each other.

RIP integration

Today’s RIPs include integration and job reporting features that are increasingly valuable in a graphic production environment, as they allow users to monitor their devices, collect ink-use metrics and identify busy periods and bottlenecks, based on the numbers of jobs—or total area—printed in each day, week and month. This information can even be reported directly to the production manager’s smart phone.

Further, today’s RIPs provide page layout and colour control, but the next generation of features will include seamless integration with web-to-print online portals, the ability to accept and process variable data, links for cloud-based systems, communications via Job Definition Format (JDF) and Job Messaging Format (JMF) and, of course, tools to measure ink consumption and Delta E colour accuracy.

[5]

[5]In Ryerson’s testing, tiny crop marks were examined to check ink registration between the CMYK channels.

An inkjet roundup

Following the preliminary study, IDEAlliance and Ryerson are launching their first Inkjet Roundup, which extends and formalizes the test parameters.

As the process continues, IDEAlliance will provide a set of images and instructions to participating inkjet press suppliers, who will then print samples and send them back to Ryerson and CalyPoly for measurement and data collection. The data will then be published and reported to the industry as further metrics are defined and standardized.

Abhay Sharma is a professor and former chair at Ryerson University’s School of Graphic Communications Management (GCM) in Toronto. For more information, contact him via e-mail at sharma@ryerson.ca[6]. To participate in the inkjet roundup program, contact Joe Fazzi, vice-president (VP) of media production technologies for IDEAlliance, via e-mail at jfazzi@idealliance.org[7].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Arizona350-GT.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Colour-Gamuts.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Arizona480gt.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Costing-Report.png

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/5.jpg

- sharma@ryerson.ca: mailto:%20sharma@ryerson.ca

- jfazzi@idealliance.org: mailto:%20jfazzi@idealliance.org

Source URL: https://www.signmedia.ca/setting-standards-for-colour-accuracy-and-ink-consumption/