Sign Shop Profile: FusionCast

Signs to remember

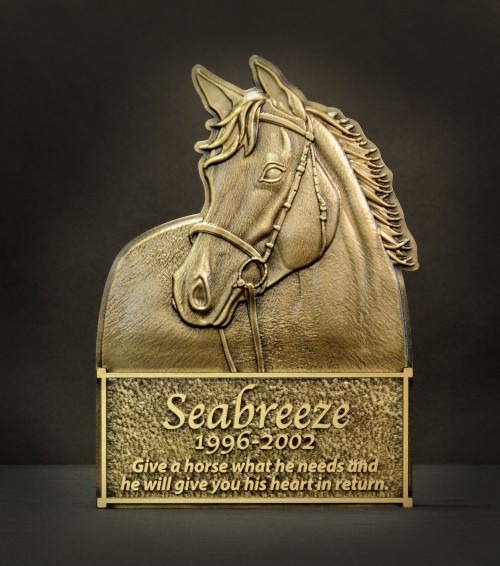

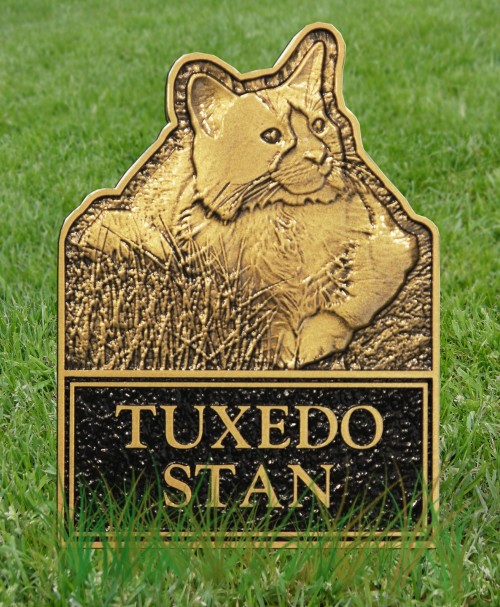

Another growing market for FusionCast has been the memorial industry. Sadly, much like tee signs on golf courses, cast-metal memorial items are being stolen from cemeteries. A $200 metal vase, for example, may carry $17 to $26 in scrap value. At one site in Burlington, Ont., an entire statue went missing!

Another growing market for FusionCast has been the memorial industry.

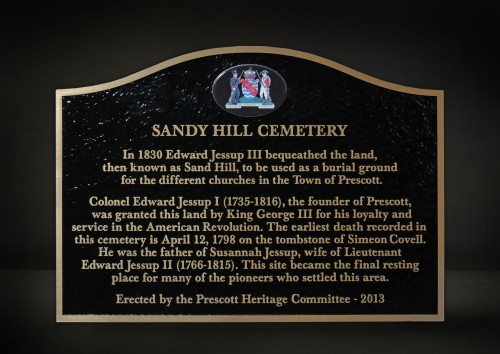

Another growing market for FusionCast has been the memorial industry.While the memorial market continues to be dominated by bronze and granite, FusionCast has worked with funeral homes, churches and synagogues to customize commemorative recognition and dedication products. For interior signs and plaques, especially, one of the advantages of the cold-cast composites’ relatively low weight is they can simply be hung with French cleats on drywall, without needing additional structural support.

“People underestimate how much work is involved in mounting a solid cast-bronze piece indoors,” says Rod Pilon, the company’s memorial market sales manager. “The wall is going to need to be reinforced, which is certainly not a one-person job. Using engineered cast metal just makes things so much easier for the facility managers.”

Building the business

Given the unusual nature of its manufacturing process, however, it has been challenging for FusionCast to build awareness.

Trade shows have helped gain some traction in the architectural market, for example, but the tendency for professionals in that industry is to continue to specify traditional cast metals for plaques, without considering alternatives. To counter this issue, FusionCast has focused heavily on outreach to organizations like the Society for Experiential Graphic Design (SEGD) and the American Institute of Architects (AIA), in the hope its product data can eventually make its way into their members’ in-house construction specifications.

The architectural market is very broad. In addition to architects themselves, FusionCast has worked with universities and other institutions, military organizations and historic societies.

Recently, the company provided eight plaques to the heritage department of the municipal government for Niagara Falls, Ont., to commemorate historic buildings along the city’s Queen Street.

“This was a high-profile opportunity to show how cold-cast composites could provide the same esthetic qualities as foundry-cast metals and withstand a wide range of environmental conditions, from freezing winters to summer heat,” says Ken Auty, who specializes in the architectural market. “Our design team worked closely with the city as the signs went through a review process involving a series of approval committees and then to arrange and oversee installation. Working with municipalities requires extreme attention to detail.”

In addition to these business-to-business (B2B) dealings, FusionCast is directly courting consumers, who order signs for their homes and cottages. The company’s business-to-consumer (B2C) initiatives include a promotional program in Home Hardware stores and an online ‘sign builder’ tool on its website to help these customers learn what is possible with the cold-casting process.

FusionCast has also expanded the range of signs it offers by producing dimensional letters. Its first halo-lit channels letters adorn a new Brooks Brothers clothing store in Ann Arbor, Mich.

Growing needs

When the new owners purchased FusionCast and began the R&D process, they came up with a ‘wish list’ of equipment and resources they would need to expand the business and further commercialize its output. Over the years, these included the recyclable wax moulds, a 1-m (42-in.) wide planer and a 9.3-m2 (100-sf) curing oven with a ‘cooking pan’ system to create composite sheets.

In 2010, FusionCast moved from its original 929-m2 (10,000-sf) Mississauga warehouse to a 1,394-m2 (15,000-sf) location in nearby Oakville, Ont. In addition to more space for its growing inventory of equipment, the company was able to add a low-VOC paint booth, computer numerical control (CNC) moulding machine, casting room and showroom for customers.

Compared to the old building, which had been adapted piecemeal as needed, the new space was laid out with a master plan, taking flow into consideration to design a true manufacturing facility. It also has more energy-efficient heating, ventilating and air conditioning (HVAC) and lighting, with the intention of achieving Leadership in Energy and Environmental Design (LEED) certification in the future.