Sign Shop Profile: FusionCast

by all | 14 April 2014 1:30 pm

[1]

[1]Pictured are: (back row, left to right) Randy Shermet, general manager (GM); Andrian Manoil, production specialist; Tod Kennedy, production specialist; Mattin Tateyama, production manager; Wayne Greene, production specialist; Adam Raby, senior designer; Ben Morgan, marketing co-ordinator; (front row, left to right) Rod Pilon, memorial, home and cottage sales manager; Brittni Pryputniski, office manager; and Davin Crawford, junior designer. Photos courtesy FusionCast

By Peter Saunders

FusionCast is a sign manufacturer that came about by fluke. One day in 2007, a sign dealer and his manufacturing partner, who had been mixing different combinations of polymers and metals in a warehouse in Mississauga, Ont., discovered a blend of high-density urethane (HDU) and bronze had solidified in the bottom of a bucket. The mix resembled a hockey puck. Naturally, being Canadians, they extracted it and hit it around the floor with sticks.

The resulting abrasions peeled away some of the HDU ‘skin’ to reveal the metal within. When they sanded it down, they realized they had inadvertently formulated a lightweight—but still strong and durable—alternative to the traditional, foundry-produced cast metal used in plaques and memorials. The key was to place high concentrations of metal where they would be seen, i.e. on the sign face, and lower concentrations elsewhere.

Lacking the technical and financial resources to fully develop a new product line, however, they decided to sell the business to a group of investors, who saw market potential in the process. With prices for bronze, aluminum and copper rising, there was the sense a less expensive ‘cold-cast’ product could gain favour with sign customers.

The composite material was also seen as a ‘green’ alternative, since the process took place at room temperature and involved less metal overall, no smelting of raw materials and no heavy metals in the casting. It would meet California-style regulations for low levels of volatile organic compounds (VOCs) in its coatings. The lower weight—approximately half that of traditional cast bronze— would save on shipping and the business could reuse about 95 per cent of its wax mould materials. Further, the cold-casting process does not create any harmful emissions or pollutants and can use up to 100 per cent reclaimed metal.

[2]

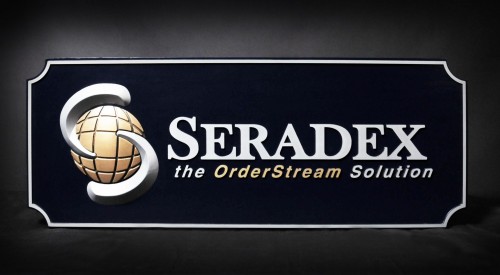

[2] [3] The signs can also be decorated with corporate colours.

[3] The signs can also be decorated with corporate colours.

With these factors in mind, the new owners patented the technology, hired polymer experts and continued research and development (R&D) efforts to perfect the product line. Randy Shermet was named general manager (GM) and he brought on additional staff members as needed.

Joining the club

The first market where they found success was golf courses, which offer steady demand for durable, uniformly designed signs posted in many locations, from entrance to exit. In the U.S., especially, golf tee signs made of cast bronze, copper and, to a lesser extent, aluminum are often stolen and sold off for their high scrap-metal value.

Working with two distributors—Golf Supply House (GSH) and Eagle One Golf (EOG)—and the Professional Golfers’ Association (PGA), FusionCast quickly became a popular custom supplier of tee markers, directional signs, information plaques and property signs for both public and private golf courses around the world, with installations as far away as Europe, China, India and Australia.

“In essence, the value of our products is their lack of value,” says Ben Morgan, marketing co-ordinator for FusionCast, “as they are worthless to scrap metal dealers, but still offer the necessary resistance against the elements—and most golfers’ temperaments—and the ability to simulate traditional cast textures, represent photography with relief sculptures and even cast different kinds of metals in the same sign, which is unattainable through traditional casting.”

“Our membership loves the clean, classic look provided by FusionCast,” says Wade Beaudoin, superintendent at St. Thomas Golf and Country Club in Union, Ont. “Our customized range yardage sign has been the perfect fit for our redesigned driving range.”

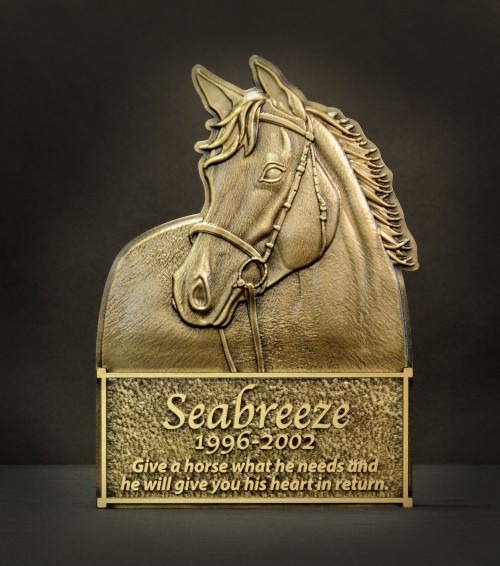

Signs to remember

Another growing market for FusionCast has been the memorial industry. Sadly, much like tee signs on golf courses, cast-metal memorial items are being stolen from cemeteries. A $200 metal vase, for example, may carry $17 to $26 in scrap value. At one site in Burlington, Ont., an entire statue went missing!

[4]

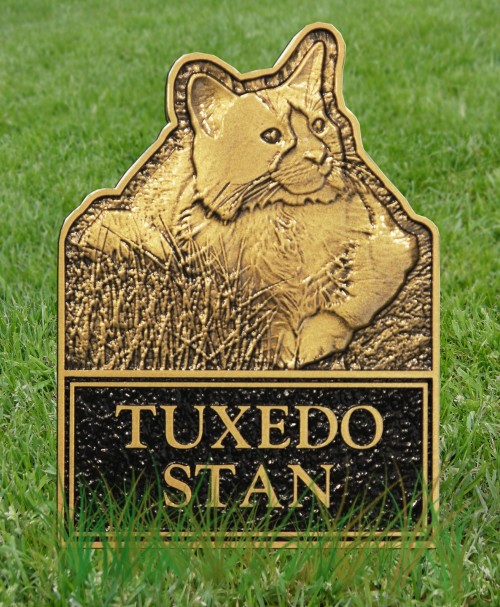

[4] [5] Another growing market for FusionCast has been the memorial industry.

[5] Another growing market for FusionCast has been the memorial industry.

While the memorial market continues to be dominated by bronze and granite, FusionCast has worked with funeral homes, churches and synagogues to customize commemorative recognition and dedication products. For interior signs and plaques, especially, one of the advantages of the cold-cast composites’ relatively low weight is they can simply be hung with French cleats on drywall, without needing additional structural support.

“People underestimate how much work is involved in mounting a solid cast-bronze piece indoors,” says Rod Pilon, the company’s memorial market sales manager. “The wall is going to need to be reinforced, which is certainly not a one-person job. Using engineered cast metal just makes things so much easier for the facility managers.”

Building the business

Given the unusual nature of its manufacturing process, however, it has been challenging for FusionCast to build awareness.

Trade shows have helped gain some traction in the architectural market, for example, but the tendency for professionals in that industry is to continue to specify traditional cast metals for plaques, without considering alternatives. To counter this issue, FusionCast has focused heavily on outreach to organizations like the Society for Experiential Graphic Design (SEGD) and the American Institute of Architects (AIA), in the hope its product data can eventually make its way into their members’ in-house construction specifications.

The architectural market is very broad. In addition to architects themselves, FusionCast has worked with universities and other institutions, military organizations and historic societies.

Recently, the company provided eight plaques to the heritage department of the municipal government for Niagara Falls, Ont., to commemorate historic buildings along the city’s Queen Street.

“This was a high-profile opportunity to show how cold-cast composites could provide the same esthetic qualities as foundry-cast metals and withstand a wide range of environmental conditions, from freezing winters to summer heat,” says Ken Auty, who specializes in the architectural market. “Our design team worked closely with the city as the signs went through a review process involving a series of approval committees and then to arrange and oversee installation. Working with municipalities requires extreme attention to detail.”

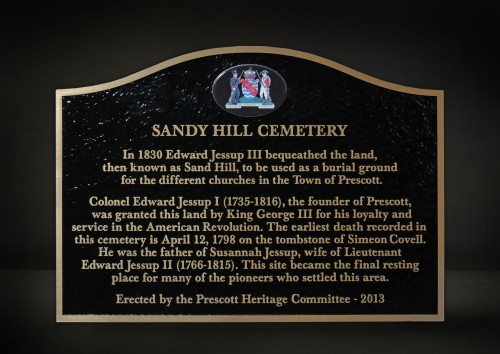

[6]

[6]Within the architectural market, FusionCast often works with municipal historic societies. This sign was produced for the town of Prescott, Ont.

In addition to these business-to-business (B2B) dealings, FusionCast is directly courting consumers, who order signs for their homes and cottages. The company’s business-to-consumer (B2C) initiatives include a promotional program in Home Hardware stores and an online ‘sign builder’ tool on its website to help these customers learn what is possible with the cold-casting process.

FusionCast has also expanded the range of signs it offers by producing dimensional letters. Its first halo-lit channels letters adorn a new Brooks Brothers clothing store in Ann Arbor, Mich.

Growing needs

When the new owners purchased FusionCast and began the R&D process, they came up with a ‘wish list’ of equipment and resources they would need to expand the business and further commercialize its output. Over the years, these included the recyclable wax moulds, a 1-m (42-in.) wide planer and a 9.3-m2 (100-sf) curing oven with a ‘cooking pan’ system to create composite sheets.

In 2010, FusionCast moved from its original 929-m2 (10,000-sf) Mississauga warehouse to a 1,394-m2 (15,000-sf) location in nearby Oakville, Ont. In addition to more space for its growing inventory of equipment, the company was able to add a low-VOC paint booth, computer numerical control (CNC) moulding machine, casting room and showroom for customers.

Compared to the old building, which had been adapted piecemeal as needed, the new space was laid out with a master plan, taking flow into consideration to design a true manufacturing facility. It also has more energy-efficient heating, ventilating and air conditioning (HVAC) and lighting, with the intention of achieving Leadership in Energy and Environmental Design (LEED) certification in the future.

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/group-photo-1091.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/northern-comfort1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/Seradex1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/Seabreeze1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/Final_Tuxedo1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/03/Sandy-Hill-Cemetery1.jpg

Source URL: https://www.signmedia.ca/shop-talk-sign-shop-profile-fusioncast/