How does state-of-the-art printing equipment incorporate these new capabilities?

JR: Ultimately, we like to say even the most advanced printer is stupid. What I mean by that is, although, mechanically, the printer needs to be operating efficiently and the nozzles have to be firing precisely, it’s the RIP software that drives the printing and ensures the inks fire at the correct time and in the correct way.

To achieve the correct colours in UV print, three critical elements need to work together: the viscosity of the ink has to line up with the firing capability of the printheads and the curing ability of the lamps. We call this the UV printing trifecta.

Newer devices have achieved this trifecta and can run the whole process twice as fast as previous generation printers. These innovative inkjets use specially formulated inks, precise printheads, and high-quality UV lamps to deliver a very high level of performance. With an advanced inkjet, you can hit more Pantone hues and achieve amazing colour that explodes off the page without the results looking unnatural. This is because the colours are balanced, and the gradations are smooth.

How are newer RIP programs helping PSPs take advantage of expanded ink gamuts?

JR: Another way of looking at the printing process is to say printers are simply painting with the palette they are given. The RIP is responsible for providing that palette by supplying the printer with the best possible colour data.

Today’s RIP software uses colour engines that can provide a multitude of different colour libraries. These libraries include information for printing on uncoated, process coated, and other types of media. Users can even edit a colour library depending on what they need, so the next time, the printer will have those edits already incorporated. All of these advances help users produce the best possible prints.

How have all of these changes affected UV print’s colour matching capabilities?

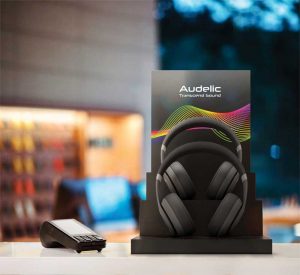

Point-of-purchase (POP) displays are among the many applications where maintaining the integrity of brand colours is important.

JR: Generally speaking, there has been vast improvement in the ability to match colours. Over time, manufacturers have developed inks that actually help enhance the colour space, rather than just throwing splashy colours on the substrate.

It can take time to develop an ink capable of satisfying the formulation demands of the printing process, as well as the colour demands for expanding the gamut. However, when companies invest in researching and developing those inks, the result can be a precise and balanced ink formulation that blends with the other inks to produce a widened colour space.

Some companies develop transition colours by using light cyan or light magenta, instead of coming out with new inks and adjusting their software to accommodate the changes. Others develop new inks and adjust the dot and wave patterns to ensure a fluid transition with no choppy breaks. Blending is managed by the RIP software, where the ink’s fine droplet sizes and minute spread is paired with instant curing. On the microscopic level, these changes create expanded gamut capability and allow you to seamlessly transition from high contrast colours to subtle shading.

What do you see happening in the next few years with ink colour gamuts for the UV market?

JR: There are always ink innovations in development, some of which may turn out to be fads, and others which will have staying power. For example, gloss and white inks are currently popular, and metallic inks were previously of interest. Among the advances people in the industry are currently discussing are photoelectric, phosphorescent, and reflective inks.

Ink technology will continue to evolve, and manufacturers will adjust their offerings based on how popular these inks prove to be once they come to market. The process is always working towards achieving balanced colour. As these newer products mature in the market, they may be further developed for qualities such as added durability and improved adhesion.

Notes

1 For more information, visit https://www.verifiedmarketresearch.com/product/uv-led-printers-market.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.