Sign Assembly: The strength of acrylic foam tapes

by all | 10 September 2015 9:48 am

[1]

[1]Images courtesy 3M Canada

By Kejian Zhang

With thousands of signs guiding people every day, their structural integrity needs to be a top priority, no matter their particular size or shape. There are many ways to achieve this integrity. Traditionally, design and production engineers have fastened parts of signs together with welds, rivets, nuts and bolts, screws and other mechanical techniques. Today, as the sign industry has adapted to work with new materials, these techniques have been joined by structural adhesives and high-strength acrylic foam tapes, which instead hold materials together by surface attachment. These options can help meet customers’ expectations for the quality of a sign’s appearance beyond the limitations of traditional assembly methods by serving as virtually ‘invisible’ fasteners.

Improving appearance and peace of mind

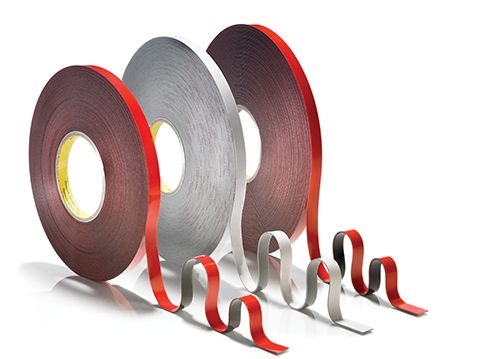

Since the 1980s, thousands of engineers, designers and manufacturers around the world have worked with acrylic foam tapes to create tough, long-lasting fasteners, especially for lighter alloys and composite materials where non-mechanical attachment methods are preferable. These materials have included products used in commercial building construction and the transportation market, from commercial airliners to personal vehicles.

By integrating strong and durable tapes, manufacturers have eliminated the need for millions of screws, rivets and welds, creating smoother, esthetically pleasing surfaces and improving the longevity of their products. In this sense, acrylic foam tapes have become the ideal combination of performance, durability and ease of use.

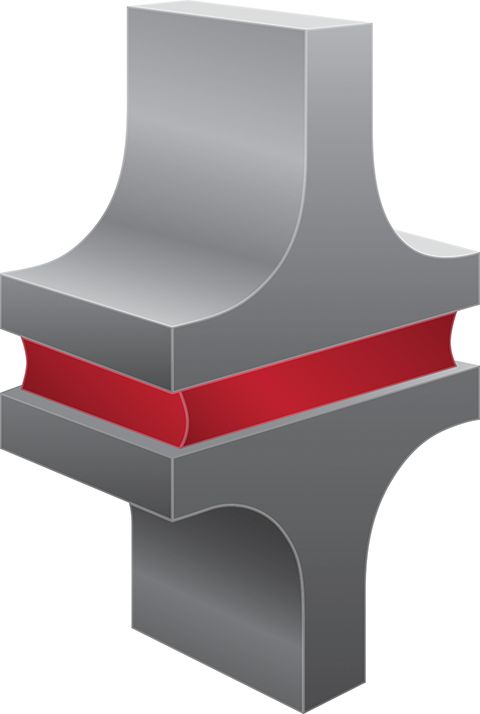

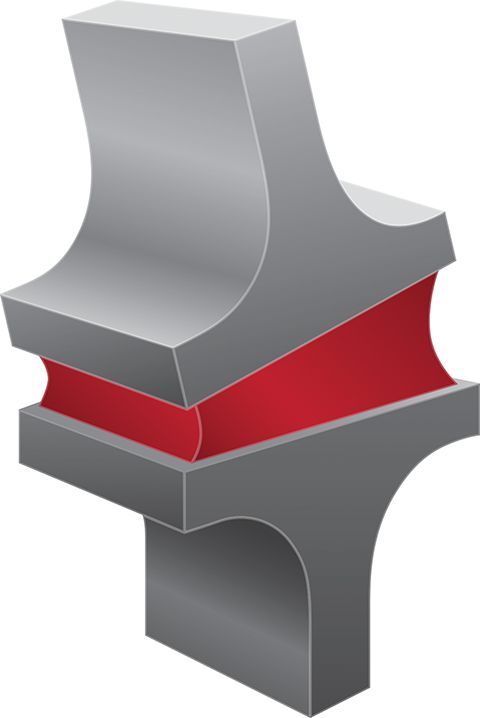

Unlike conventional foam tapes, which feature a thin adhesive film on each side of a foam core, acrylic foam tapes have adhesive all the way through. As they exhibit both viscous and elastic characteristics (and are therefore ‘viscoelastic’), the foam core absorbs energy and dissipates stress to achieve a high level of strength, dampen vibrations and maintain a durable bond over time (see Figure 1).

The seamless appearance of a sign without traditional mechanical fasteners has proven highly appealing and, indeed, is expected by many of today’s designers. By using acrylic foam tapes, their products are not just bonded for strength, but simultaneously sealed—thanks to the 100 per cent closed-cell construction of acrylic—for greater resistance to corrosion and other types of weathering.

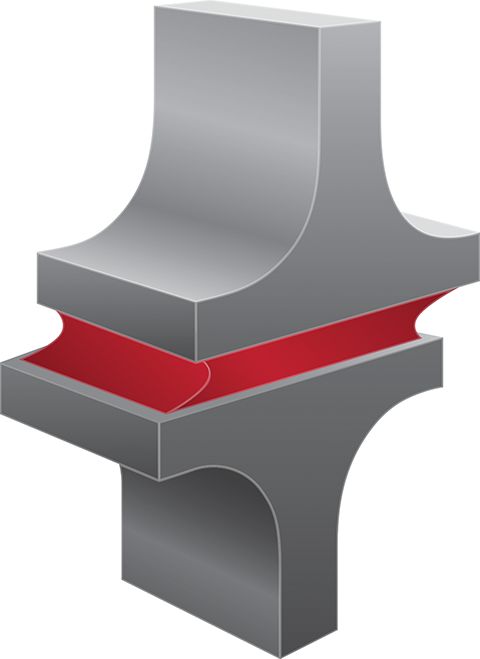

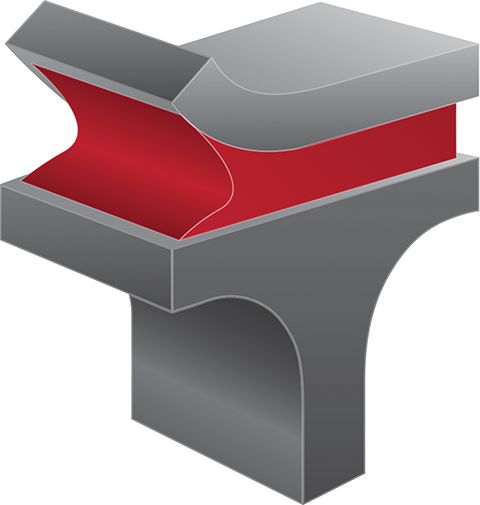

The uniform stress distribution offered by adhesives and tapes can compensate for thermal expansion and contraction. Lighter and/or thinner materials can be used without concerns about distortion, splitting or crazing at each fastening point, as they do not damage the integrity of substrates through drilling, screwing or welding (see Figure 2). The elimination of holes reduces opportunities for rust and corrosion by sealing against environmental conditions, for example, and bi-metallic and other dissimilar materials can also be adhered with a smooth, consistent appearance. This means designers can decide exactly how they want their sign to look and which materials they will use to achieve that appearance.

Acrylic foam tapes also offer total cost savings, as there is little or no investment required for machinery and only very minimal training is needed. Tapes simplify the sign assembly process by eliminating the time-consuming labour involved in drilling, grinding, refinishing, screwing, welding and cleaning up. Further, material costs can be reduced by sourcing and incorporating the aforementioned thinner materials, rather than the thicker materials required for mechanical fasteners and welds.

Improving on structural adhesives

Adhesives for sign assembly are available as liquids, pastes, tapes, films and shaped solids. Each option offers its own characteristics that need to be considered with regard to application effectiveness and efficiency.

Depending on the specific type of adhesive, it is possible to bond metals, wood, rubber, ceramics, composites, engineering-grade plastics, glass and more. As a rule of thumb, structural-strength adhesives must offer a minimum of 6,895 kPa (1,000 psi) in overlap shear strength, which allows them to replace mechanical fasteners and welds in bonding the load-bearing parts of a product.

Typically, most structural adhesives—like two-part acrylic and epoxies—require time to cure fully and develop greater strength before parts can be moved or handled. Fast-curing adhesives are available, but may shrink after curing and generate extra stress at the joint. Pressure-sensitive adhesive tapes, on the other hand, bond on contact for immediate handling, preventing the production bottleneck associated with drying time or fixturing.

Liquids and pastes readily fill voids to enhance mechanical adhesion. Pressure-sensitive tapes offer uniform thickness throughout a joint, confinement of the adhesive to the immediate bonding area, clean bonding without dripping or overflow and, for that matter, minimum adhesive waste.

While structural adhesives can achieve high strength along a small bond area, with an extremely thin bond line, acrylic foam tapes are beneficial because they can cover a larger bond area and no dispensing system is needed.

Tape selection considerations

Signmakers have used high-strength acrylic foam tapes to permanently bond many surfaces, including powdercoated, painted and unpainted metal, acrylic, polycarbonate, rigid and flexible polyvinyl chloride (PVC), aluminum composite panels, fibreglass, sealed wood and glass. Typical applications include sign face panel bonding (see Figure 3), letter mounting (see Figure 4), stiffeners (see Figure 5) and light-emitting diode (LED) module attachments inside sign letters or cabinets.

High-strength acrylic foam tapes are available in various thicknesses, adhesive formulations, colours (e.g. clear, black, grey and white) and release liners. As such, they can be specified for each job’s needs, including conformability, strength, multi-material adhesion and resistance to plasticizer migration. The durability of a high-strength acrylic tape can involve resistance to high and low temperature cycles, ultraviolet (UV) light, moisture and solvents, among other factors.

The first step in choosing the right tape for a given substrate is to ensure it will stick as firmly as possible, which is a question of how easily the adhesive can flow and ‘wet out’ the surface to build a strong bond.

The next step is to ensure the tape will make contact on the bonding surfaces to form a secure connection. This is partly a question of joint design—the joint should preferably be designed for tensile (see Figure 6), shear (see Figure 7) and compression strength, not peel (see Figure 8) or cleavage (see Figure 9).

It is also important to select the right tape thickness. The optimal thickness for a particular application will depend on the size, rigidity and flatness of the substrates being attached, as well as the amount of pressure being applied to bring the surfaces together.

In general, thicker tapes will handle greater mismatches and differential thermal expansion between surfaces, providing fuller contact and sealing. For bonding rigid materials of typical flatness, 1.1-mm (45-mil) or thicker tapes should be considered. As substrate flexibility increases, thinner tapes may be used instead.

Another factor is the right amount of tape. As a general rule, for static loads (such as gravity or ‘spring back’), approximately 2,581 mm2 (4 sq in.) of tape should be used for each 0.45 kg (1 lb) of weight supported. For dynamic tensile or shear loads, such as wind loads, tape can be designed to handle 85 kPa (12 psi) of strength.

The tape should also allow for the aforementioned thermal expansion and contraction, whereby two bonded surfaces—such as metal and plastic—can experience movement relative to each other. There are tapes available today that can typically tolerate shear movement up to three times their original thickness, so long as there is already strong adhesion to each substrate. Hence, a 1.1-mm (0.45-mil) thick tape designed for such expansion and contraction can safely endure shear strain up to 3.3 mm (135 mil).

Application techniques

Most substrates are best prepared by cleaning with a 50:50 mixture of isopropyl alcohol (IPA) and water prior to applying a high-strength acrylic foam tape (see Figure 10). Exceptions that may require additional surface preparation include:

- Heavy oils—A degreaser or solvent-based cleaner may be required to remove heavy oils or grease from a surface, followed by cleaning with IPA and water.

- Heavy dirt or oxidation—Abrasive cleaning may be needed to remove heavy dirt or oxidation (rust) before cleaning with IPA and water, so as to promote adhesion across an increased surface area.

- Porous surfaces—Most porous and fibrous materials—such as wood, particleboard and concrete—need to be sealed to provide a ‘unified’ surface for tape application.

- Unusual materials—Special surface preparation may be needed for glass and glass-like materials, copper and copper-containing metals and any plastic or rubber that contains components that may migrate (e.g. plasticizers).

Priming the surface with ‘adhesion promoters’ may also improve the initial and long-term bond for many materials, such as plastics and paints.

The recommended initial bonding temperature for most acrylic foam tape applications is 15 C (60 F) or higher, with the ideal range between 21 and 38 C (70 and 100 F), allowing the pressure-sensitive adhesives to flow viscously and achieve full substrate contact. For lower-temperature initial bonding, down to 0 C (32 F), special products will be needed. Once properly bonded, however, low-temperature ‘holding’ is generally satisfactory.

Bond strength depends on the amount of adhesive-to-surface contact, which in turn depends on application pressure. Firmer pressure helps develop greater contact and, thus, improve bond strength. Typically, good surface contact can be attained by applying enough pressure to the substrates to ensure the tape itself experiences approximately 100 kPa (15 psi). Rigid surfaces, it should be noted, may require two to three times that—i.e. 200 to 300 kPa (30 to 45 psi)—just to ensure the tape experiences 100 kPa (15 psi).

While acrylic foam tapes bond on contact for immediate handling, the strength of their bond increases with time, as the adhesive flows onto and ‘wets out’ the surfaces. At room temperature, approximately 50 per cent of ultimate bond strength will be achieved after 20 minutes, 90 per cent after 24 hours and 100 per cent after 72 hours. The adhesive’s flow will be faster at higher temperatures and slower at lower temperatures.

The right combination

Many signs today have greater visual impact because they were assembled with strong, viscoelastic acrylic foam tapes, providing a seamless esthetic. What’s more, they are proving highly durable, with a bond that will last under even the harshest of environmental conditions.

Kejian Zhang is an advanced application development and technical services specialist for the industrial adhesive and tape division of 3M Canada, which supplies a wide range of products for the sign and graphics industry. For more information, contact him via e-mail at kzhang3@mmm.com[2].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/09/Picture-8-Three-VHB-Tapes.jpg

- kzhang3@mmm.com: mailto:kzhang3@mmm.com

Source URL: https://www.signmedia.ca/sign-assembly-the-strength-of-acrylic-foam-tapes/