Sign industry pivots to change the trajectory for the better

by all | 4 February 2021 2:31 pm

By Sonia Yooshing

[1]

[1]Since the pandemic started, Canadian sign industry professionals have risen in solidarity to meet the challenge by pivoting their business to lend a helping hand to the community.

Although 2020 is finally behind us, the path forward may feel uncertain as the challenges we faced in the past year continue. That said, one thing has never been clearer: We are in this together and, to change the trajectory for the better, we need to work together to build a safer future we can all share.

Creating an end-to-end supply-chain network

Since the pandemic started, we have seen unprecedented examples of how Canadian sign industry professionals have risen in solidarity to meet the challenge by pivoting their business to lend a helping hand to the community. One such example is Toronto Stamp, a 113-year-old, family-run sign shop in Scarborough, Ont., that successfully created a supply-chain network to serve Ontario’s personal protective equipment (PPE) needs.

The company has played many roles and taken on several projects since it was established in 1907, including producing stamps, stencils, nameplates, signs, tags, and badges out of a 650-m2 (7000-sf) facility. The shop even helped Ontario develop its first license plates.

[2]

[2]Toronto Stamp successfully created a supply-chain network to serve Ontario’s personal protective equipment (PPE) needs.

In the face of the global pandemic, the company chose to shift from its usual production to develop the province’s first end-to-end supply chain for face shields and other PPE, including face masks, sneeze barriers, social distancing decals, and instructional labels. The shop has since produced more than five million face shields.

“We won a contract with Health Canada to deliver four million face shields in just two months,” said Jimmy Williams, the company’s general manager. “Like many small businesses, we had the opportunity to pivot our business to stay alive—it was something we were able to do based on our experience and expertise.”

[3]However, at the outset, the shop faced many challenges. The primary barrier being very few understood its capabilities or potential.

[3]However, at the outset, the shop faced many challenges. The primary barrier being very few understood its capabilities or potential.

Toronto Stamp had always been recognized in the rubber stamp industry, but it was not consistently at the top of the list when people were looking for solutions to their unique situations. Therefore, the company sought assistance from other businesses in the province.

“When we found out we won the government contract, we knew we were never going to be successful alone—an industry in Canada was going to get this done,” said Williams. “At first we partnered with more than 20 other Ontario businesses, and then invested in offering in-house and vertically integrated automation.”

Toronto Stamp led several businesses from across the province to build an end-to-end supply chain. The network, Unitum Consortium (Latin for ‘United Community’), consisted of businesses that represented all stages along the supply chain. Some of these included:

- 3G Packaging Corp.;

- Baysquare Technologies Pvt. Ltd.;

- EM Plastic & Electric Products Ltd.;

- Maverick Exhibits;

- Pattison Sign Group;

- Piedmont Plastics;

- Sherway Group;

- Spectra Advertising and Signs;

- Swift Components Corporation;

- Threadfin Business Solutions; and

- Trotec Laser Canada Inc.

“Jimmy Williams reached out to me, and I immediately asked him how I could help,” said Robert Ascenzi Jr., chief operating officer at Spectra Advertising and Signs. “This was a great way to get people back on staff. It also allowed everybody a chance to feel like they could help in some way.”

Supporting local communities and essential businesses

[4]

[4]Omnify Lighting has produced several community and healthcare face shields, social distancing decals, and acrylic barriers for various businesses.

Gemini, a wholesale supplier that has provided innovative solutions to the signage and graphics community for more than 65 years, too, joined in the fight against COVID-19 by producing face shields and shield components along with supplying bio partitions to various essential businesses.

“Many of our facilities are in smaller, rural communities without the same access to supply as larger metropolitan areas,” said the company’s general manager, Kerri Eady. “Considering our known capabilities among our neighbours, we received requests to lend a hand and produce shields and protective components for our local fire departments, police services, and health-care workers. We also supported essential businesses that were required to remain open but needed to protect their employees quickly and efficiently.”

The shop created capacity in its laser-cutting and assembly departments through the initial need for PPE products. Following rising demands, the company established resource shifts to continue operations beyond standard hours while keeping teams physically distanced and adhering to all necessary safety protocols.

Being a custom manufacturer of signage components, Gemini was uniquely positioned and used the same operator and graphic team skillsets to facilitate components. Although not much of the operation was altered to recognize the need, knowing the importance and contribution its teams were able to offer to the local community made it even more significant.

That said, the shop’s challenges were not unique. The pace necessary to react appropriately in uncharted territory resulted in a level of ambiguity.

“It was the willing collaboration among leaders in our industry and the ongoing sharing of information and best practices that made the difference, putting some certainty to the doubt and some clarity to the indecision,” said Eady.

[5]

[5]Gemini joined in the fight against COVID-19 by producing face shields and shield components along with supplying bio partitions to various essential businesses.

The shop plans to continue to support local communities as needed; however, now that there is a strong and innovative supply network available through the industry and others for PPE-related products, it intends to renew focus on its traditional routine of supplying signage solutions to partners.

As companies continue to find unique ways to assist clients, wholesale trade printer SinaLite has produced a range of products, including social distancing floor graphics, health and hygiene decals, and protective face shields to help print partners in Canada.

“Our industry has been greatly impacted by the pandemic, and we wanted to do something to create opportunities for our print partners so they can adapt to the current circumstances,” said the company’s vice-president of marketing, Brian Meshkati. “We wanted to be able to contribute to the movement and education needed to stop the spread of the virus by reminding people of healthy hygiene practices and the importance of social distancing.”

[6]

[6]Wholesale trade printer SinaLite has produced a range of products, including social distancing floor graphics, health and hygiene decals, and protective face shields to help print partners in Canada.

In response to Premier Doug Ford’s call for Ontario’s manufacturing companies to step up, Omnify Lighting, a mid-sized business in custom light-emitting diode (LED) backlighting solutions, headquartered in Toronto, made the decision to design and build face shields for frontline workers.

“When we saw what was on the market, we realized we had the right high-quality materials in our inventory, and the correct production equipment, not to mention the skilled labour, to make this a reality quickly,” said Omnify CEO Will Andrew.

The company added extra manufacturing shifts and worked with local businesses to enhance production capacity. Omnify also collaborated with local medical workers to test the product and provide design iterations to make the end product better.

The shop has since produced several community and healthcare face shields, social distancing decals, and acrylic barriers for various businesses.

Leading by example

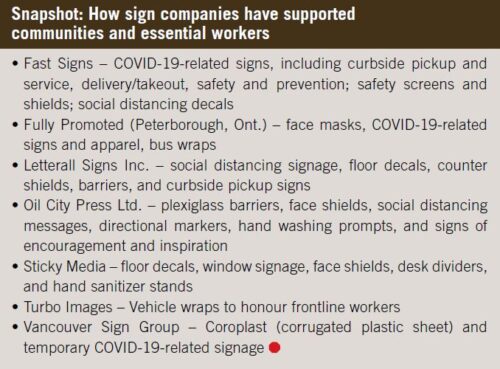

This is just a sampling of how the sign industry has led by example and helped the community push through incredible difficulties, meet urgent needs, adapt, evolve, and build resilience for the future, and it only continues to emerge stronger as we move forward.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/fork-lift.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/conveyor.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/2-4-2021-1-15-43-PM.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/Healthcare.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/Gemini-1.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2021/02/Floor-Graphics-1.jpg

Source URL: https://www.signmedia.ca/sign-industry-pivots-to-change-the-trajectory-for-the-better/