Sign Shop Profile: CanSign

by all | 30 May 2013 8:30 am

[1]By Peter Saunders

[1]By Peter Saunders

In 1979, when Mike Halprin moved with his parents from Winnipeg to Canmore, Alta., the Bow Valley town had no sign shop to speak of. Halprin’s father, Josh, who had done some screenprinting in the past, quickly seized the opportunity to fill the niche. He began working out of his basement and garage. By 1982, he had his own shop and was providing a wide variety of signs.

“Dad did a lot of everything back then,” says Halprin. “We were fairly poor when we moved here and limiting yourself in a small community would be like shooting yourself in the foot. He hand-painted signs on wood, glass, vehicles and plywood, then would turn to screenprinting as soon as someone ordered more than 20 of the same sign.”

Handing out his business card, Halprin’s father realized the town presented a strong opportunity for orders to keep coming in

“Canmore was a town of around 2,000 people back then,” Halprin says, “but as soon as he got his foot in door, he found a lot of people through word of mouth who needed signs. They would see some cool lettering on a window and felt they needed it too!”

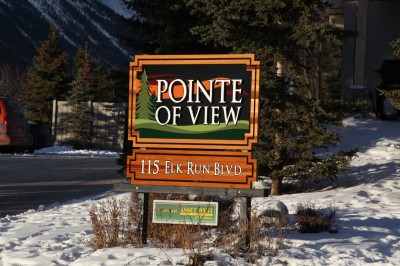

The Canmore sign company became known as CanSign, which the younger Halprin now co-owns and serves as production manager, working alongside four employees and his father. Its workload includes everything from decals, vinyl banners and vehicle wraps to aluminum traffic signs, dimensional fascia signs and hand-carved Western red cedar logos.

“We avoid screenprinting today, as the chemicals are way too nasty, but we do everything else, from short runs to massive jobs,” he says. “It’s a custom shop and also a sign shop in the traditional sense.”

[2]A lifetime of signmaking

[2]A lifetime of signmaking

Halprin already had a long history with the business before becoming an owner with his father. Even at 10 years old, he was weeding vinyl.

“I always loved working with my hands and being somewhat creative,” he says.

In 1989, Halprin’s father sold his signmaking equipment and began to manage a concrete business instead, though he continued to fabricate signs on weekends. In 1992, however, he got out of the concrete business and returned to the sign industry. He expanded the shop from 28 m2 (300 sf) to 84 m2 (900 sf) in 1995 and moved to the current 116-m2 (1,250-sf) location in 1996.

When Halprin was 18, he graduated from high school and began working full-time at the shop. In 2001, he moved to Vancouver, where he ran the sign division of PacBlue Printing for nearly three years. Then he returned to Canmore to help run the family business and keep it up to date by investing in newer technology.

“Dad started out using a jigsaw or scroll saw to cut sign letters,” he says. “Now we have a computer numerical control (CNC) milling machine.”

Similarly, Halprin has updated his skills over the years. In 2011, for example, he trained to become a 3M Canada-preferred graphics installer.

“It was extremely tough,” he says. “Most people who take the course only wrap vehicles, but I don’t get to be that specialized. I also have to spend time in paint booths or up in cranes installing signs! The trainers are amazing, though. I was the 34th student or so in Canada to pass the course.”

It helped that CanSign had already been using 3M’s vinyl films since 1987, when Halprin’s father started producing graphics for the 1988 Winter Olympic Games in Calgary (for which Canmore would host the Nordic skiing and biathlon events).

“Today, 95 per cent of our digitally printed and cut vinyl work uses 3M films,” says Halprin, who is currently testing the company’s EnVision film samples on a variety of surfaces.

For work in the paint booth, he has also been trained with PPG’s Matthews Paint products for signs.

“I took the course at a PPG facility in Mississauga, Ont., and the company provided phenomenal support,” he says. “We used to use a lot of sign enamel paints, but this system is easier to work with. I can now mix 75,000 colours spot-on. We signed up for their ‘gloss’ system nine years ago and we’ve since upgraded to the ‘satin’ system. We are also considering adding new paints that are low in volatile organic compounds (VOCs) to our quiver.”

[3]Made for Canmore

[3]Made for Canmore

CanSign handles sign projects from start to finish, offering design services, permit applications, engineering and construction drawings, fabrication, installation, maintenance, restoration and even neon tube repairs.

Permit applications are a particularly important process in both Canmore and nearby Banff, where bylaws intended to preserve the towns’ beauty and reduce ‘visual pollution’ significantly restrict the types of signs that can be displayed outdoors.

“Way back in the day, Canmore didn’t set many limitations,” says Halprin. “A building would simply have space allotted for a sign. Once the town started to write bylaws, Dad made sure to get involved, so the process would help everyone.”

The resulting local regulations for signs in Canmore have set square footage limits and clearances from grade to base. Light and white backgrounds are frowned upon.

“They won’t allow ‘big city’ signs,” Halprin explains. “There are no halo-lit or backlit signs, unless they were grandfathered in from years ago. Our clients may have to pay a premium to comply with the bylaws, but at least it’s easier here than in Banff, where the rules are a little more stringent and the signs are a lot more expensive. In Canmore, for example, we can use leftover bits of wood from the mill, but in Banff, all of the signs have to be made of Western red cedar.”

To stay within Canmore’s regulations while the sign industry continues to evolve, CanSign focuses much of its efforts on testing new materials as they emerge in the market. This is also important when considering the local climate.

“Materials come and go, but their manufacturers often test them in warmer, humid climates compared to here,” says Halprin. “So, we go through a lot of trial and error before we will convince our customers to use these materials.”

[4]One of CanSign’s newest projects is Elevation Place, a 7,154-m2 (77,000-sf) multi-use community facility in Canmore, primarily funded through the provincial government’s Municipal Sustainability Initiative (MSI). Set to open this year, it houses a library, aquatics centre, art gallery, climbing centre and multi-purpose rooms. CanSign was hired to design the facility’s sign system.

[4]One of CanSign’s newest projects is Elevation Place, a 7,154-m2 (77,000-sf) multi-use community facility in Canmore, primarily funded through the provincial government’s Municipal Sustainability Initiative (MSI). Set to open this year, it houses a library, aquatics centre, art gallery, climbing centre and multi-purpose rooms. CanSign was hired to design the facility’s sign system.

“We bid against several other companies for this project,” says Halprin. “Most of them are design firms that specified polymethyl methacrylate (PMMA) signs, but we did a lot of extra legwork to find materials that would help the building earn Leadership in Energy and Environmental Design (LEED) points. We’re working with bamboo-based plywood and low-VOC clearcoats. In addition to the environmental benefits, these help make the signs lighter.”

When complete, Elevation Place will feature more than 300 signs, including cut-out bamboo plywood letters, decals and aluminum signs.

A full workload

Although most of its projects are nowhere near as big as Elevation Place, CanSign’s workload has remained steady throughout Canmore’s economic ups and downs over the years.

“Businesses turn over quickly here, which is difficult for them, but good for us, since new businesses mean new signs are needed,” says Halprin. “We also ship signs nationally—including reflective aluminum signs for Parks Canada campgrounds—and sometimes internationally.”

[5]Overall, Halprin estimates 60 per cent of the company’s output is for the local market (including both Canmore and Banff), 20 per cent is for other Canadian businesses and the remaining 20 per cent is split between government and international clients.

[5]Overall, Halprin estimates 60 per cent of the company’s output is for the local market (including both Canmore and Banff), 20 per cent is for other Canadian businesses and the remaining 20 per cent is split between government and international clients.

“I have a friend in Alaska who has us ship truck decals to Idaho for him,” he says. “It’s all about your contacts. We have a lot of quotes out now and our work order board is full. It’s an endless supply.”

The company has struggled somewhat to meet that level of demand, however, because staffing has proven to be a big challenge in a small town.

“I would like to have about three more employees working in twice as much space, but it’s hard to find suitable staff,” Halprin says. “A lot of people want to work here, but some have no experience and some can only commit to a short-term position. We’ve even had people afraid of heights apply to be sign installers!”

That said, Halprin is happy with the current team.

“We have brought on a new office administrator and designer,” he says. “One young fellow, Stephen Raso, has been with us for nine years. He went through the Northern Alberta Institute of Technology’s (NAIT’s) Graphic Sign Arts Program and graduated first in his class with honours in 2010. The next step is for him to become a 3M-preferred installer, too!”

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Cansign-photos-035.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Olympic-logo-sign.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/IMG_2870.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/IMG_2914.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/IMG_2569.jpg

Source URL: https://www.signmedia.ca/sign-shop-profile-cansign/