The personal touch

As in Pat’s radio days, Masterhand clients are mainly retailers, although some custom signs are built for homes and farms.

“The town really supports us,” says Pat. “Given the population here is just over 2,500, we’ve had to become pretty well-rounded. I do vinyl cutting, painting, gilding, airbrushing, carving, gluechipping and pinstriping. We don’t have a digital printer, but there’s a shop in Swift Current, Sask., called Signs ’n Such that can do that work for us.”

Indeed, despite trends elsewhere in the sign industry, Masterhand has benefited from what Pat sees as a resurgence of interest in unique, handmade pieces.

“Technology is great, but the handmade stuff is by far the most satisfying,” he says. “Other signmakers wonder how we get so much gold leaf work out here in the Prairies, for example, but when you compare handcrafted signage to the lifetime of a digital print, you can see why many of our customers choose the former. And where many customers today seem to expect a sign in an hour, ours understand it will take a week or two.”

The benefits of handcrafted signage are all part of Pat’s pitch, particularly to new clients.

“We’re not pushy or hard-sell, but at the beginning, I’ll provide several designs, each a grade higher than the last, so they see the difference in quality,” he explains. “About 95 per cent of them go up from what they originally told us their budget was. We see a lot of upselling from a $1,000 sign to a $3,000 sign. No one blinks an eye or calls us crazy, because they realize there is skill and work behind it. It’s all about showing what you can do for your customer.”

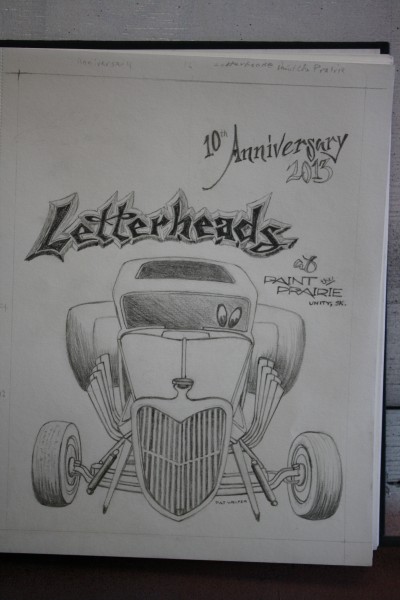

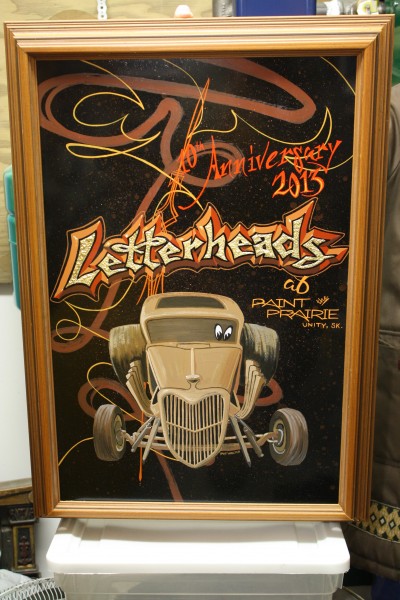

Pat Welter starts with pencil sketches before painting his panels with lettering enamel and adding gold leaf.

Masterhand’s humble facilities comprise a 7.3 x 7.9-m (24 x 26-ft) office and a 7.3 x 8.5-m (24 x 28-ft) garage full of traditional woodworking tools.

“The space is not very big,” says Pat. “Sign folks visit and wonder how I work here, but it goes in waves. Sometimes I’m solidly doing lettering work in the shop and sometimes I’m out applying vinyl decals to a fleet of trailers.”

Notably, the Welters do not use a computer numerical control (CNC) router for any of their work.