Sign Shop Profile: MitoGraphics

by all | 21 May 2015 10:52 am

[1]

[1]Photos courtesy MitoGraphics

By Peter Saunders

As the motto at MitoGraphics puts it, “We print everything except paper.” Based in Cambridge, Ont., the company produces an unusually eclectic mix of output, from signs, banners and displays to tiny graphics, decals and labels. And as its name’s Greek roots in ‘Mitos Graphikos’ suggest, similar to the Latin-based term ‘serigraphy,’ much of this output is screenprinted. (Both ‘mitos’ and ‘seri’ refer to the silk in silkscreening.)

Co-owners Kristen Danson and Sheldon Rier (pictured) have found a successful niche by marketing two divisions of their business: branding elements and industrial graphics.

Industrial origins

Perhaps surprisingly, the company was not originally set up as a graphics business at all.

“In the early 1980s, as Rier Industries, we were making pool table covers, barbecue covers and other specialty vinyl products for the industrial textile market,” Rier explains. “Some of our customers wanted to add their corporate branding to these products. So, we bought the remnants of a screenprinting operation in Toronto, moved it over to Cambridge and integrated it into what we were already doing.”

Being new to graphics, Danson and Rier read up on screenprinting techniques, attended graphics industry trade shows, brought in consultants and experimented to learn as much as they could about their additional capabilities. As more customer requests for printed materials came their way, what began as a way to add further value to existing products evolved into a new business of its own.

[2]

[2]MitoGraphics was formed when Rier Industries expanded into screenprinting.

“We were just too dumb to say no to the jobs!” Rier laughs. “We worked a lot of long hours to figure out the screenprinting business. Over time, we switched to making products where the graphic is the primary component.”

This shift also entailed a broader scope of products than vinyl and textiles. After initially printing only on flexible materials, the shop also began to handle acrylic, polystyrene (PS), glass, metals and other, more rigid substrates.

“We found some of our clients liked working with one vendor for all of their graphic needs, whether they wanted to brand vehicles, garments or transit shelters,” says Rier. “We joined the Specialty Graphic Imaging Association (SGIA) in 1989 when we were printing a lot of pressure-sensitive materials.”

The aforementioned motto—“We print everything except paper”—was adopted in the 1990s to help better define their mixed-media approach to their clients. While the range of output grew and the company moved into a larger space in 1999, Rier explains he was never interested in competing with the traditional commercial printing industry in mainstream markets like business cards and stationery.

“We rebranded as MitoGraphics in 2002 because we had really become a specialty reprographics shop,” he says, “and we started to add digital printing in 2004.”

[3]

[3]With a combination of industrial and marketing graphics, the company has made a specialty of printing on everything except paper.

Strength in adaptability

Years of experience printing on materials with tight tolerances, particularly dimensional parts, have helped make MitoGraphics highly adaptable to changes in the market.

“We’re a diverse team of craftspeople, working with a diverse range of equipment,” says Rier. “Our workflow is constantly changing and we devote a lot of resources to staying ahead of the curve. Fortunately, most of our core clients are very long-term. In many cases, we’ve done work for them for more than 15 years. And referrals have always been a huge part of our business.”

One key to this adaptability has been understanding the various benefits and limitations of analogue and digital printing—and knowing when to combine both processes for the same project, such as when producing a colour logo on a sign before adding lettering.

“Digital printing offers a broad colour range, high speed, high resolution and variable data, but a lot of our jobs are not suitable for digital because of their requirements for opacity and durability,” Rier explains. “Screenprinting is superior for specialty inks, like metallics, opaque layers and adhesives, and offers a lot of advantages in terms of outdoor durability. Most of what we consider our ‘marketing’ materials are digitally printed, but most of our industrial graphics benefit from the versatility of screenprinting.”

By way of example, MitoGraphics frequently screenprints elevator control panels. Using client-supplied fascia panel substrates, the company is able to provide a quick turnaround.

[4]

[4]The company also has a digital department for solvent-based inkjet and dye sublimation printing.

“Most of our customers buy short runs of graphics, but fairly frequently,” says Rier. “They treat us like an extension of their own operations, as we can insert ourselves into their production process. We can do their research and development (R&D), prototyping, testing and production.”

These customers are mainly spread out across Canada, but there are also key accounts in the U.S. and MitoGraphics has even exported large projects to China.

In another example of niche output, the company colour-matches and prints variable data on 129-mm2 (0.2 sq in.) identification (ID) tabs for the agricultural industry, which must be able to withstand being stored for long periods at temperatures as low as -200 C (-328 F). These tend to involve large volumes and short lead times. The company uses tin-coated steel so the tags can be magnetized for adhesion to vials.

“They’re used for categorization, so they have to be very colour-stable,” says Rier.

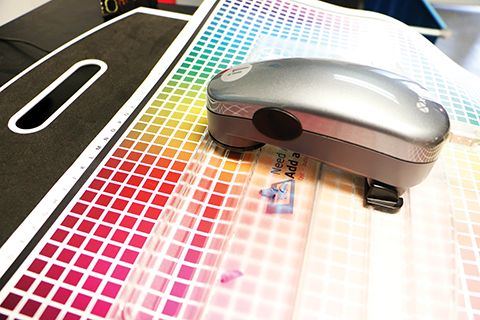

[5]

[5]Colour matching is extremely important for tight-tolerance industrial graphics.

Combining processes

As for digital printing, MitoGraphics has relied on six Mimaki inkjet presses, cutters and plotters over the years, including solvent-based and dye-sublimation models.

“We were doing high-volume dye-sub printing before anyone seemed to know what it was,” says Rier. “We also have a laser cutter with a digital vision system that we can integrate into our workflow. We may not identify ourselves as a traditional sign shop, but we do a lot of work for other sign shops and marketing companies.”

The in-house finishing department offers sewing (for banner edges), lamination, die cutting, hot foil stamping, laser engraving, waterjet cutting and full fabrication of metals and plastics.

“Many of our products are cut to shape or three-dimensional (3-D) and made from multiple materials,” Rier explains.

The company has done everything from wrapping a vending machine with imaged graphics to screenprinting ceramic inks directly onto large glass panels. With this range of techniques at hand, Rier also credits the company’s success to its long-time membership in SGIA.

“We’ve been very involved with them over the years,” he says. “We often rely on the SGIA network for technical support. In a way, we’ve evolved along with them.”

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/Kristen-Danson-and-Sheldon-Rier.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/edit11.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/Mito-Process_Prepress.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/Mito-Process_Wide-Format-Printing.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/Mito-Process_Colour-Matching.jpg

Source URL: https://www.signmedia.ca/sign-shop-profile-mitographics/