By Jerry Fireman

By Jerry Fireman

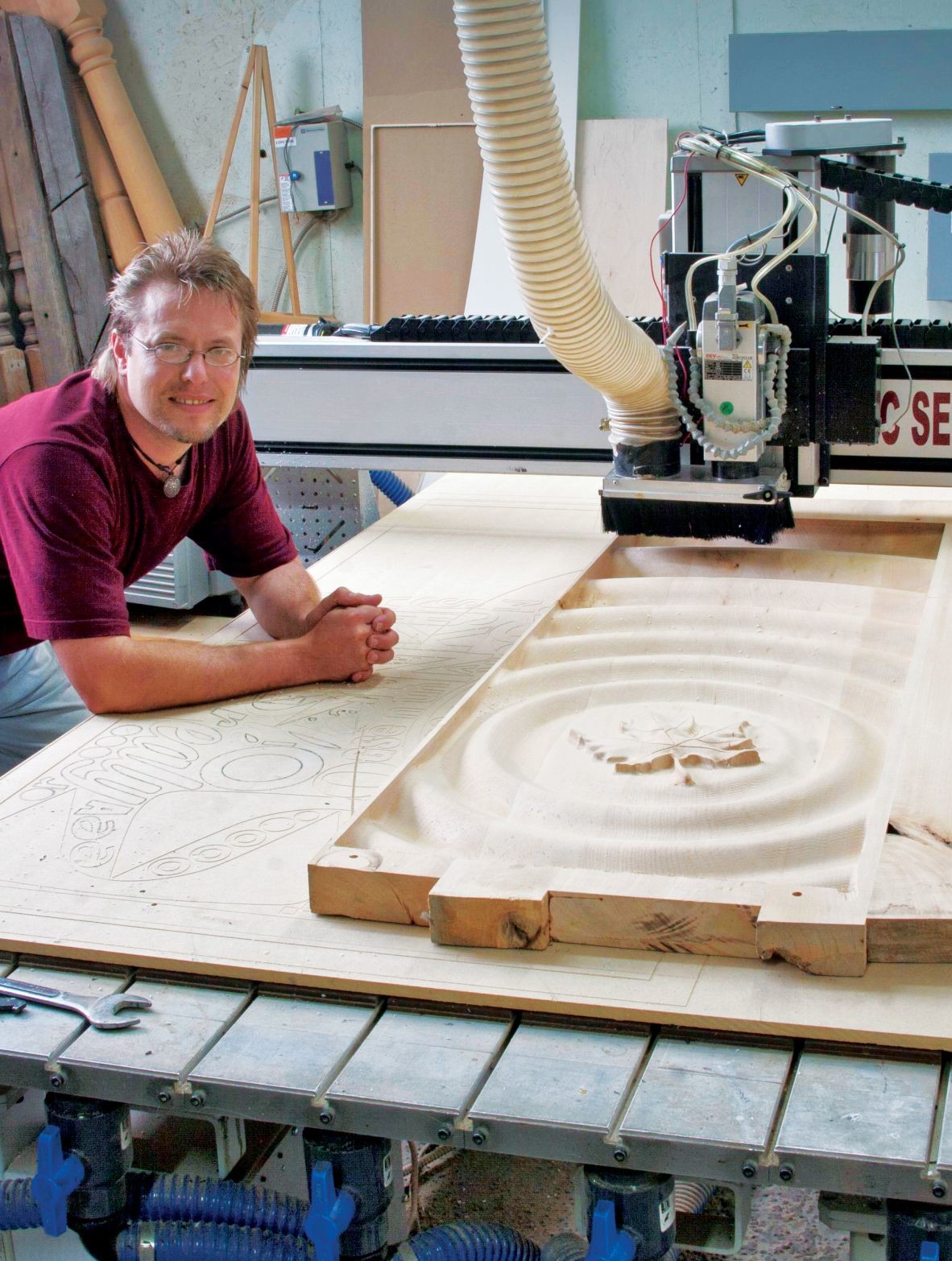

Grant Nicholson, who currently runs Nicholson Design in Owen Sound, Ont., worked as a graphic designer for more than 20 years. After he built his own house, however, he decided he was tired of working only with software.

Instead, he looked for tools that would allow him to turn design concepts into physical objects by himself. He decided to purchase a computer numerical control (CNC) router to produce dimensional signs and other objects, working with natural materials, such as wood. He has now operated it for three years.

Today, Nicholson’s in-house capabilities for producing complex, three-dimensional (3-D) signs cannot easily be matched by his local competitors.

“The router has helped me rise to the cream of the crop in the sign business in my region,” he says. “It pays for itself every year by increasing the quality of my work and reducing the amount of time required to produce it.”

He also uses it for a wide range of woodworking purposes, creating everything from wooden floor inlays to newels for stairposts (the ornamental first posts at the bottom of a stairway).

“I think of it as a ‘virtual chisel,’” he says.

Envisioning arts

Envisioning arts

Nicholson earned a visual arts degree in 1992. Since then, he has worked for both small and large companies, including Transcontinental Printing and Quebecor Printing. He also spent nine years working for a local government agency, designing signs, publications, museum exhibits and tourism promotions. That was just before he started his own firm.

“The availability of economical CNC machines with the ability to produce finely detailed work was a big factor in encouraging me to strike out on my own, considering how labour-intensive the process used to be,” he says. “The great sculptors had teams of assistants who would carve out basic forms. The sculptors supervised their work and made the finishing touches. In modern times, we cannot afford these teams of people, yet we yearn for beautiful work that is not mass-produced, but rather matched to our individual tastes.”

As Nicholson started planning his business, he considered several potential production methods. He looked at waterjet and plasma cutting, for example, but did not want to be constrained to producing two-dimensional (2-D) objects. He liked how 3-D printing could produce an endless variety of shapes, but it was limited to a few different types of plastic.

CNC routers, on the other hand, combined the abilities to produce 3-D objects and to work with nearly any type of plastic, foam, wood and synthetic wood.

“So, I looked at a number of different routers,” he says. “Maintenance and reliability were my biggest concerns. I was afraid if the machine broke down, my new business would die!”

After meetings and demos, Nicholson had confidence in the reliability of the device he ended up purchasing.

Today, he says the machine has lived up to its promise and been “incredibly reliable.”

“It has never required any service and has had almost no downtime in the three years of operation,” he says.