Software allows artists to draw by hand before their designs are adapted for dimensionality.

A custom process

Behind the ‘Disneyland’ effect is a 132-step process, customized for each project. Computer-aided design (CAD) software turns hand-drawn sketches into 3-D models, with cutting paths configured for CNC routing. While the foam is cut, metal frames are welded and inserted as needed to maintain structural stability.

“We CNC our pieces to 65 to 70 per cent of their level of detail and then the rest is done by hand,” Nolan says. “We also hand-paint everything we make, by airbrush.”

Before painting, the aforementioned hardcoat is added to ensure long-term durability, particularly for characters and signs that will be installed outside a clinic.

“What stands out in the market are (a) the creative level we go to and (b) our finished product quality,” says Nolan. “We try to put in a lot of ‘gags’ during the design stage, for example, so people see something new each time they pass by our characters.”

This creative and labour-heavy approach was particularly evident in a recent self-promotional display SYC created for a trade show, which won in the Unique Signs category of Sign Media Canada’s 2016 National Sign Competition and was even named Best in Show. Among other stacked elements, it featured a pig with a scarf, a goose wearing pilot’s goggles and a bluebird gripping the bars of its cage.

“Some of our dentists aren’t specifically focused on young children, so they don’t necessarily want the kiddy stuff,” says Nolan. “For those customers, we create more sophisticated, graphic-based and realistic pieces. To provide an idea of everything we can do, we annually publish a hardcover book, showcasing all of our favourite projects of the past year. That has become one of the best marketing tools we have.”

Expressing adaptability

In addition to its higher-end displays, SYC also has some clients with smaller budgets paying closer to $50,000 U.S. for IDS environments.

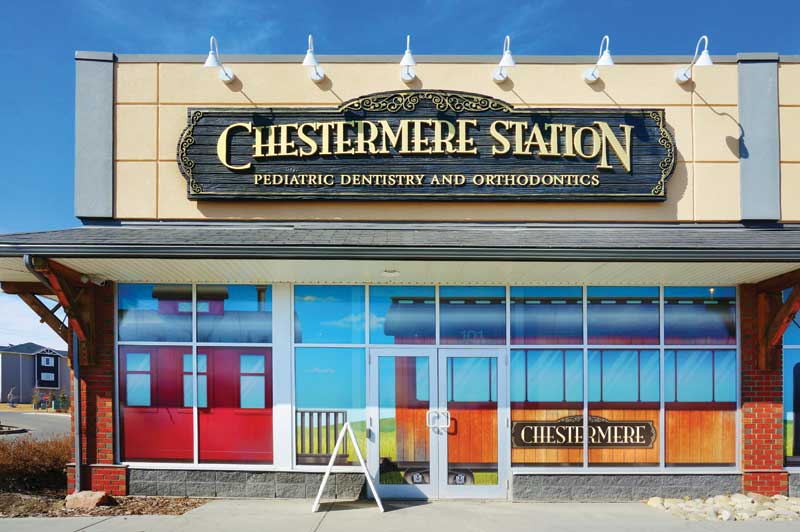

For clinics that do not specialize in serving younger children, a more sophisticated, graphic-based and/or realistic approach is taken.

“We know some of our customers are walking past our storefront based on price alone and that’s okay for now,” says Nolan, “but down the line, we want to bring them in by launching a lower-cost ‘express’ spinoff line of products.”

The express concept, still in early development, is to combine predesigned dimensional pieces with digitally printed murals. In addition to making IDS’s services more affordable for smaller clinics, this would help SYC provide modular pieces for multi-

location clients, e.g. car dealerships seeking to keep bored kids entertained while their parents are shopping for a vehicle.

“It’s still a new idea, but it represents a way to duplicate our expertise,” Nolan says.

SYC now operates two locations, including its 2,230-m2 (24,000-sf) head office in Calgary and another 1,858-m2 (20,000-sf) production facility in Pompano Beach, Fla. Between them, they have many projects on the go at the same time, totalling about 40 per year.

“SYC still serves shopping centres and theme parks, but IDS is the focus of this company’s future, as it’s the biggest growth opportunity,” says Nolan. “The dental industry accounts for 90 per cent of the work SYC does. It’s a niche market, but a significant one that’s large enough for us. And we would also like to do projects for hospitals and other pediatric facilities.”

Technology is continuing to change the nature of SYC’s activities. The company has worked with the Oculus Rift virtual reality (VR) headset, for example, to allow dentists to test out different concepts in simulated spaces well before production. And some IDS printed murals now integrate augmented reality (AR) features.

“We don’t sit around on our hands!” Nolan laughs.

Building an Arch