Soft signage, hard profits

By Mike Wozny

The sign and graphics industry continues to be digitized, yielding improvements in speed, quality, price, performance and substrate versatility. One of the most exciting opportunities to arise from this ‘digital transformation’ is the ability to print on a wide array of textiles, either directly or through a transfer-paper process.

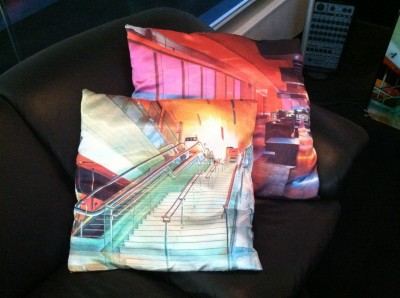

Digital printers with this capability are opening new revenue streams for sign, graphic and display providers from markets like soft signage, home décor (e.g. drapes, pillows, furniture) and apparel (e.g. scarves, clothing). According to InfoTrends, which provides market research and strategic consulting for the digital imaging and document systems industry, sales of digital textile printing equipment and inks are rising at a compound annual growth rate (CAGR) of 30.7 per cent.

There are a number of benefits—for both signmakers and their customers—associated with the digital printing of graphics on textiles.

The digital transformation

It is clear digital technology has made its mark across most segments of the printing industry, including display graphics, and is now mainstream. Benefits have included the ability to produce shorter runs profitably, with little or no make-ready waste; to quickly and easily personalize materials, such as customized signs for specific locations and point-of-purchase (POP) display graphics advertising particular products; and to reduce production cycle times.

These benefits have applied not only to signs and graphics, but also to commercial printing, packaging and other marketplace segments. For most purposes, it is worth noting, there is no longer much of a debate over quality compared to analogue processes. Today’s escalated quality of digital printing meets most print buyers’ requirements.

In the midst of these benefits and advances for display graphics, there is an opportunity to migrate banners away from traditional vinyl-based materials to textile-based substrates. For both print-service providers (PSPs) and print buyers, replacing vinyl offers many advantages.

Textile benefits

The digital printing of textiles has differentiated many display graphics providers from their traditional competitors and is now becoming more common, for the following reasons:

Higher margins

The market for vinyl-based signage is highly competitive, driving prices down. Generally, printed vinyl graphics are going for $1 or less per square foot. In the market for finished soft signage, on the other hand, prices are often between $4 to $6 per square foot or higher.

This is because of the higher-end look and feel of fabric graphics. Buyers find they attract more public attention and draw a greater response to their advertising.

“Fabric is just a much cleaner, nicer material for printed signage,” says one graphics provider. “It is much higher-end than vinyls. Our customers are large retailers and they are willing to pay a bit more to have a nice fabric print.”