Soft signage, hard profits

by all | 24 September 2013 8:30 am

[1]

[1]Photos courtesy EFI

By Mike Wozny

The sign and graphics industry continues to be digitized, yielding improvements in speed, quality, price, performance and substrate versatility. One of the most exciting opportunities to arise from this ‘digital transformation’ is the ability to print on a wide array of textiles, either directly or through a transfer-paper process.

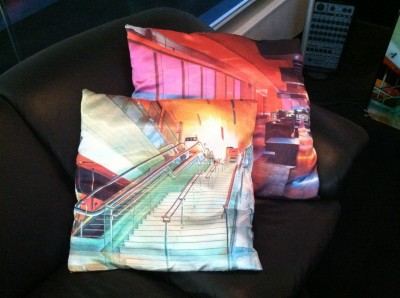

Digital printers with this capability are opening new revenue streams for sign, graphic and display providers from markets like soft signage, home décor (e.g. drapes, pillows, furniture) and apparel (e.g. scarves, clothing). According to InfoTrends, which provides market research and strategic consulting for the digital imaging and document systems industry, sales of digital textile printing equipment and inks are rising at a compound annual growth rate (CAGR) of 30.7 per cent.

There are a number of benefits—for both signmakers and their customers—associated with the digital printing of graphics on textiles.

The digital transformation

It is clear digital technology has made its mark across most segments of the printing industry, including display graphics, and is now mainstream. Benefits have included the ability to produce shorter runs profitably, with little or no make-ready waste; to quickly and easily personalize materials, such as customized signs for specific locations and point-of-purchase (POP) display graphics advertising particular products; and to reduce production cycle times.

These benefits have applied not only to signs and graphics, but also to commercial printing, packaging and other marketplace segments. For most purposes, it is worth noting, there is no longer much of a debate over quality compared to analogue processes. Today’s escalated quality of digital printing meets most print buyers’ requirements.

In the midst of these benefits and advances for display graphics, there is an opportunity to migrate banners away from traditional vinyl-based materials to textile-based substrates. For both print-service providers (PSPs) and print buyers, replacing vinyl offers many advantages.

[2]

[2]Textile printing applications include soft signage, home décor and apparel.

[3]

[3]Textile benefits

The digital printing of textiles has differentiated many display graphics providers from their traditional competitors and is now becoming more common, for the following reasons:

Higher margins

The market for vinyl-based signage is highly competitive, driving prices down. Generally, printed vinyl graphics are going for $1 or less per square foot. In the market for finished soft signage, on the other hand, prices are often between $4 to $6 per square foot or higher.

This is because of the higher-end look and feel of fabric graphics. Buyers find they attract more public attention and draw a greater response to their advertising.

“Fabric is just a much cleaner, nicer material for printed signage,” says one graphics provider. “It is much higher-end than vinyls. Our customers are large retailers and they are willing to pay a bit more to have a nice fabric print.”

Ease of installation and storage

As it is both lighter and less likely to wrinkle than vinyl, soft signage is much easier to install cleanly. It can be hung or stretched in a tension frame.

Then, after their initial use, fabric signs can more easily be stored for future reuse. They are less likely to crack, crease or otherwise be damaged during storage. And if a wrinkle or crease does somehow appear, the material can simply be ironed or pulled flat again.

Lower transportation costs

Another advantage of the lower weight of fabric compared to vinyl is it therefore costs less to transport. In fact, shipping costs can be reduced by as much as a factor of 10 for soft signs compared to ‘hard’ signs, as they can be folded to fit into smaller shipping containers without worrying about damage. A 3 x 3-m (10 x 10-ft) banner may well cost $30 to ship instead of $300.

Lighter materials are especially useful for trade show graphics, since exhibitors pay drayage costs by weight when moving materials on and off the show floor.

[4]

[4]Lighter than vinyl and less likely to wrinkle, fabric graphics can be hung or stretched in a tension frame.

Sustainability

Since they are more environmentally friendly than vinyl-based substrates, particularly in terms of a lower carbon footprint, textiles help given companies a greener image.

Also, for the aforementioned reasons relating to storage and transportation, fabric signs are more likely to be reused, whereas other sign materials are often discarded after their initial application.

A range of printers

Display graphics providers who are now planning to add a digital textile printer to their production facility will need to consider a number of factors. There are many options available today, ranging from low-end wide-format inkjet printers—some modified to handle fabrics, others designed from the beginning for use with some textile-based substrates—to high-end super-wide-format industrial printers.

Obviously, these represent a range of investments. Signmakers need to compare the upfront equipment costs with the market value of the results they can achieve. Some of the more expensive super-wide-format printers, for example, can often earn a surprisingly rapid return on investment (ROI), even when they are not used as frequently as a smaller printer.

Dye sublimation

Industrial textile printing has relied on dye sublimation. This process involves dyeing the fabric directly or via heat-transfer paper. Compared to other textile printing methods, dye sublimation is particularly good at producing continuous-tone images and bright colours, resulting in a better-looking graphic. The colourants are highly resistant to abrasion and fading.

Dye sublimation printing is completely odourless. The resulting fabrics drape well and can be washed and dried without wrinkling their graphics. Similarly, the finished product can be folded without cracking or other image damage for ease of shipping, storage and reuse.

While some shops today are entering the soft signage market with a less expensive ‘latex’ durable aqueous inkjet printer first, after they see the full profit and growth potential of the market, an industrial super-wide-format press becomes the logical next step.

[5]Textile sublimation: Direct vs. transfer

[5]Textile sublimation: Direct vs. transfer

There are two methods for digitally printing fabric graphics: direct-to-textile printing; and the use of transfer paper. There are pros and cons to each process. The best way to determine which method to use is to consider how the graphics will need to perform.

Printing on transfer paper helps provide better control over dot gain immediately after the ink is jetted, as there is less dot gain on transfer paper than on fibrous textiles. This helps ensure edge definition and a high-quality appearance for closely viewed images. Transfer printing is bes-suited, therefore, for such applications as pop-up displays and in-store graphics.

The other process, where the ink is jetted directly onto the textile and then sublimated, allows the graphics to penetrate through the substrate to the second side. Flags, windsocks and soft signs are often printed with this method for a see-through appearance. There may be looser edge definition, but when viewed from a distance, the difference in appearance can be negligible.

Textiles designed for direct printing are manufactured with coatings that help control the ink as it is jetted. The stronger the coating, the better the control. Sometimes, the coating can inhibit some of the dye from migrating completely to the other side.

Today, there are many different textiles available for direct and transfer sublimation printing. To get pointed in the right direction, signmakers should contact vendors and inform them of the final application. And after receiving samples, it is a good idea to test several materials to find the one that works best for the job.

Mike Wozny is a strategic product manager at Electronics for Imaging (EFI), which manufactures Vutek super-wide-format dye-sublimation fabric printers. This article is based on a webinar he presented on behalf of the Specialty Graphic Imaging Association (SGIA). For more information, visit www.efi.com[6] and www.sgia.org[7].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Fabric-image-4.jpeg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Fabric-image-3.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Fabric-image-6.jpeg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Fabric-image-1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/01/Fabric-image-7.jpeg

- www.efi.com: http://www.efi.com

- www.sgia.org: http://www.sgia.org

Source URL: https://www.signmedia.ca/soft-signage-hard-profits/