Spectra Advertising: From hand painting to digital printing

by | 8 May 2019 3:11 pm

By Sonia Yooshing

[1]

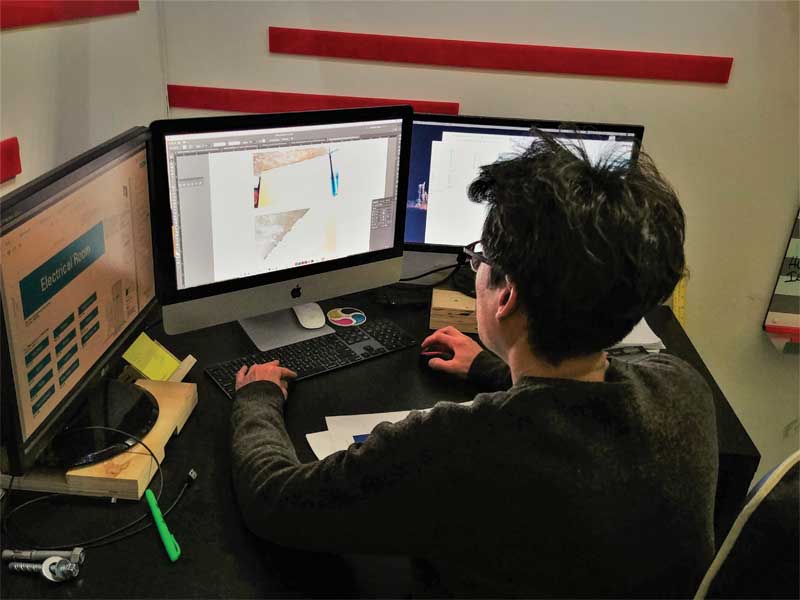

[1]Now, with Robert Acsenzi Jr., as chief operating officer, Spectra is looking at expanding its business.

A family-owned sign business, Spectra Advertising was founded by Robert and Tony Ascenzi in the early 1990s, who started out by hand painting billboards. Ever since, this sign shop has established itself as a premier signmaking company, and today, nearly three decades later, the business has grown to a 836-m2 (9000-sf) large manufacturing facility, which creates almost everything in-house—from interior to exterior. The shop specializes in a range of signage items from wayfinding to Accessibility for Ontarians with Disabilities Act (AODA) signs, pylons, and light-emitting diode (LED) displays. Within a short span, the sign shop has worked with architectural firms such as MacLennan Jaunkalns Miller Architects (MJMA), ARK, and Entro, just to name a few.

Sign Media Canada recently spoke with Ontario Sign Association’s (OSA’s) president and 2018 sign professional of the year, Robert Ascenzi Jr.; and Young Professionals Network’s (YPN’s) director and 2018 International Sign Association (ISA) Elite, Matthew Lavery, to learn more about Spectra Advertising, the shop’s philosophy, and what the future holds for the business.

Sign Media Canada (SMC): What is the history of your shop and how has it grown over the years?

Spectra Advertising (SA): Founded in June 1993 by Robert and Tony Ascenzi in Concord, Ont., Spectra has come a long way in the past 26 years. With great values, it has grown into a successful and reputable sign company. Today, Spectra has 16 employees including, but not exclusive to, three project managers, two graphic designers, an installation foreman and manager, an administrative assistant, and a talented installation team.

We are dedicated to innovation and use contemporary automation and technology to provide exceptional products and delivery times for our clients. Our slogan, “A sign is an identity, identify with us,” motivates us to provide our customers with value for their money.

SMC: What type of signage does your shop primarily make? What are some of the projects you have been working on recently?

SA: What started as a mom and pop store has grown by leaps and bounds over the years and, today, we handle nearly 85 per cent of the signmaking process in-house. We specialize in creating signage for various industries, from new community centres to hospitals, university, and colleges. We love projects where we can fabricate and install exterior pylons, interior wayfinding signs, AODA signage, and donor feature walls.

In the past, we have worked with institutions such as the University of Toronto, York University, Humber College, and Peel Region School Board. Most recently, we created signage for two Ontario-based projects—the Laurentian University in Sudbury and Bernie Morelli Recreation Centre in Hamilton.

We pride ourselves on the quality of our products and services and paying close detail to the client’s needs. We value every project and treat each contract as a priority.

[2]

[2]Sign manufacturing day provides students with a better understanding of what education is needed or will advance them in the field of signmaking.

SMC: What equipment do you currently use to complete your sign projects?

SA: At the moment, we have two computer numerical control (CNC) MultiCam routers, one HP-FB 500 Scitex flatbed printer with ultraviolet (UV) curable inks, a Roland VersaCAMM VP-540 digital printer, two 1524-mm (60-in.) wide Royal Sovereign laminators, welding and fabrication equipment, as well as a Summa plotter. We also own a photopolymer processor and hot stamping machine for AODA signage and a 3.6- x 7.3-m (12- x 24-ft) spray booth, which serves as a Matthews’ paint mix station. Our in-house machinery eliminates the need for an intermediary, which saves time and lowers prices to satisfy our client’s needs and deliver quality signs on time.

Also, our installation equipment, which consists of six pickup trucks, a boom truck, and a 4.5-m (15-ft) long trailer, ensures the final product meets our customer’s satisfaction.

SMC: What does your planning and design process involve?

SA: We are a goal-oriented company with an emphasis on efficiency, quality, and professionalism. Our staff and resources are of the utmost quality. We operate with a family approach, capturing the strengths of all those involved, to implement an open line of communication between our clients as well as project members. This ensures all needs are met within the parameters outlined in the proposal. Establishing timelines for communication, production, and installation allows us to meet our customer’s requirements with ease.

SMC: How is technology changing your business? What is the key to staying successful in this industry?

SA: Nearly three decades ago, all signs at Spectra were handpainted by signmakers. Today, everything is created with the help of printers. The sign business has evolved tremendously over the past few years.

The key to staying successful is to keep pace with the times. Because our industry moves so fast, it is important to stay on top of the latest products and equipment on the market, so we can best serve our clients. Having the ability to design graphics, create signage in various forms using our in-house machines and expertise, as well as install this signage once it is completed allows us to stay ahead in the game.

[3]

[3]The 3.6- x 7.3-m (12- x 24-ft) spray booth serves as Matthew Lavery’s paint mixing station.

SMC: What are the future plans for your business?

SA: We would like to build our business revenue slowly but steadily, and perhaps, double our gross income in the next five years. Now, with Robert Ascenzi Jr., as chief operating officer, Spectra is looking at expanding its business.

“I believe in our senior staff to take us into the next decade,” says Ascenzi Jr.

While Andrew Ascenzi is working with the education committee on the OSA board, Matthew Ascenzi is involved in a co-op student exchange program with St. Elizabeth Catholic High School in Thornhill, Ont., and ISA’s Sign Manufacturing Day event.

Spectra believes getting the youth involved will only make the sign industry better. “We are as passionate about teaching as we are about the sign industry,” says Matthew Lavery. “We believe providing the youth with more information and knowledge about the signmaking business will help us in the long run and take the industry to the next level.”

According to Lavery, Spectra works directly with the school’s manufacturing and engineering students and has developed a really good rapport with the school, its students, and staff. Many students have successfully completed their co-op program with great feedback and excellent marks. Their goal is to continue to reach out to the youth and promote the sign industry, as well as other participating shops with respect to long-term career opportunities. Sign manufacturing day also provides students with a better understanding of what education is needed or will advance them in the field of signmaking.

For more information, visit www.spectra-signs.com[4].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/SIGN-MEDIA-17.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/SIGN-MEDIA-10.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/05/BERNIE-MORELLI-2.jpg

- www.spectra-signs.com: http://spectra-signs.com/

Source URL: https://www.signmedia.ca/spectra-advertising-from-hand-painting-to-digital-printing/