“Some sign shops will also laminate with UV stabilizers to protect the inks,” he says. “You don’t need to laminate against moisture, though, as the ACMs are already water-resistant.”

Beyond direct-print substrates, ACMs are also used as backings for other signs. Many signmakers use the 0.2-mm thick material on the backs of channel letters and the 0.3-mm version for sign cans.

“The edges are protected in the letters or cans, so there is not much threat of any impact or breakdown for these applications,” says Isbell. “They perform well in both hot and cold environments.”

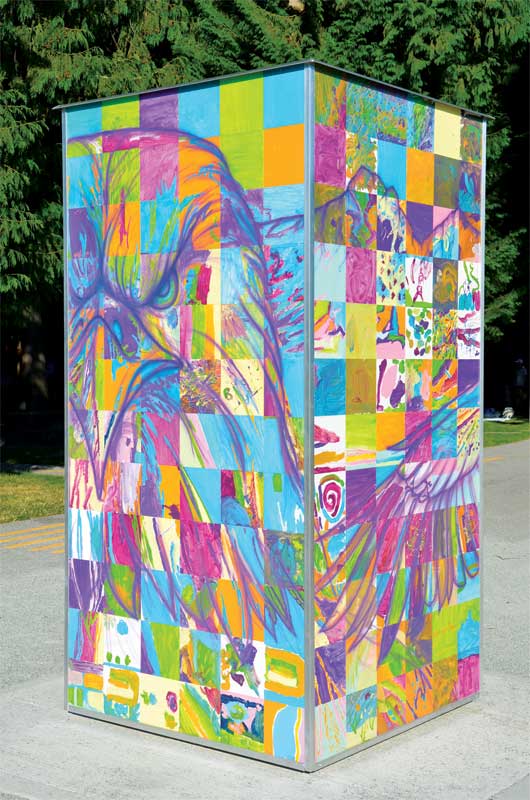

In Pitt Meadows, B.C., artist Brad Dinwoodie designed a mural dubbed ‘Eagles in Flight’ that was painted by residents of the community onto Gatorfoam tiles.

Photo courtesy Susann Sigmund

In the future, he predicts, in addition to tweaking printer-friendly topcoatings and other types of finishes for ACMs, the sheets will likely be made available in larger sizes to meet sign shop requests—and thicker, for that matter, since the materials are already so much lighter than the plywood they have replaced in outdoor signage.

“A larger sheet might well need a thicker skin to mitigate the impact of handing,” says Isbell.

Maximizing metal

The main advantages of ACMs over plywood for exterior signs are their lower weight, which means easier handling for installers, and their stronger weatherability.

“In the U.S., ACMs have been approved by the Department of Transportation (DOT) for construction zone signs,” says Shaun Allen, a product manager for sign supply distributor Grimco. “They are less expensive than thicker-gauge aluminums, but also more rigid than thinner aluminums. So, you even have signs that would previously have been aluminum switching to ACMs.”

Grimco carries a variety of ACMs, from Nudo’s AlumaCorr, which sandwiches a corrugated/fluted polypropylene (PP) co-polymer between two aluminum faces, to Max Metal, whose polyethylene (PE) core can reportedly stand up to being hit with a hammer.

“An open-flute design is more subject to denting,” Allen explains. “The choice will depend on where the material will be used. Some sheets are designed for mounting vinyl graphics, but the majority have shifted toward flatbed direct printing. And some are intended more for architectural purposes, such as brushed silver canopies.”

As with Piedmont’s digital-grade ACMs, Grimco has recently tested Max Metal Digital with major printer manufacturers to optimize its ink adhesion.

“The world of digital printing has really changed ACMs,” says Allen. “The selection will continue to broaden for different applications.”

With files from 3A Composites, Piedmont Plastics and Grimco. For more information, visit www.graphicdisplay.com, www.piedmontplastics.com and www.grimco.ca.