Talking shop with SRS Signs & Services

by | 6 December 2018 10:28 am

By Samantha Ashenhurst

[1]

[1]

When Shane R. Storie founded SRS Signs & Services in 1999, he started small, changing lightbulbs in burnt-out signs around Winnipeg, but soon moved beyond strictly service and into production. From humble beginnings with just a vinyl plotter and a couple rolls of material, Storie eventually transformed SRS into the one-stop, in-house manufacturing sign shop it is today.

The company’s 27 staff members—and Binx, the shop dog—work out of a 929-m2 (10,000-sf) facility located in the heart of Winnipeg. The business’s success hinges on an overall commitment to customer satisfaction: regardless of project size, team members work with their clients every step of the way—from design to production to installation.

[2]

[2]The Winnipeg sign was a huge undertaking for SRS. The project required a concentrated team effort, reliant on the experience and craftsmanship of dedicated employees.

The SRS team was recognized at this year’s Best of Canada’s Sign Industry Awards (BOCSIes), taking top honours in the channel letters category. The winning project had been commissioned in the summer of 2017 by the Canada Summer Games Host Society. Winnipeg had been selected as host city for the Canada Summer Games, and the Society wanted to commemorate the event by donating a permanent keepsake. The SRS team was thrilled to be selected for the project, which would be comprised of 2.4-m (8-ft) high colour-changing channel letters, spelling out the name of the city.

Sign Media Canada spoke with SRS project manager Erika Kasper to learn more about the shop’s philosophy and what was involved in bringing this special project to light.

Sign Media Canada (SMC): What type of signage does your shop primarily make? What type of work have you been handling recently?

Erika Kasper (EK): SRS makes everything from parking to pylon signs. There is no job too big or too small for us to transform into reality.

As ‘parking sign season’ winds down, the team has been preparing to battle the early winter by finishing up our outdoor vinyl requests—everything from wrapping signal boxes to perforated graphics. No matter the time of year, we always have a range of projects on the go.

SRS handles 100 per cent of the signmaking process in-house. We have three full-time graphic designers on staff who render all production files from printing to computer numerical control (CNC) cut files and installation patterns. Our vinyl team lays all graphics on-site and we cut all substrates with a CNC or shear—a machine the staff playfully dubbed ‘Ed Shearin.’ We also have an automotive paint booth, so we’re able to industrially paint elements in-house as well.

SMC: What does your planning and design process involve?

EK: When it comes to project development, communication is key. As such, project managers and our director of operations work closely with the design team to ensure customer requests are fulfilled in a realistic way.

When it comes to customer service, we don’t cut any corners: we make the time to brainstorm with our clients to determine how we can bring their idea into the realm of possibility for production. We provide them with samples and construct prototypes when needed to ensure the project’s vision is fulfilled.

In a smaller city like Winnipeg, satisfying customers and establishing a good reputation is vital. We’ve remained successful in this industry by being good to our customers and we rely on their satisfaction. Truly caring about each project and the customer is what has kept us going.

SMC: Your team recently received a BOCSI for its Winnipeg channel letter sign installation. How long did the project take to complete? How many workers were involved?

EK: The purchase order from the Host Society was received May 11, 2017, with a hard deadline for completion of July 27—one day before the Canada Summer Games held its opening ceremony. We had exactly 11 weeks to turn a concept into a reality.

The project was a huge undertaking for the shop. It required a concentrated team effort, which was reliant on the experience and craftsmanship of dedicated employees. The entire staff came together, working extra-long hours and going above and beyond. It was such an exciting project that pretty soon everyone was involved in it. Office and production teams came together to help move the massive letters around the shop—we even had to hire additional staff members to help out. It was incredible to watch raw material transform into such an iconic symbol for our city in such a short period of time.

SMC: What kinds of tools and equipment were used to create this project?

EK: Our trusty shear, ‘Ed Shearin,’ was purchased specifically to execute this project, as it allowed us to cut the large sheets needed to produce the massive letters. To expedite the process, we also purchased an additional aluminum welder.

[3]

[3]The colour of the channel letters can be changed depending on the type of event taking place or to co-ordinate with the season.

SMC: How many light-emitting diodes (LEDs) were used? Were there any considerations that had to be taken into account in regards to lighting aspects?

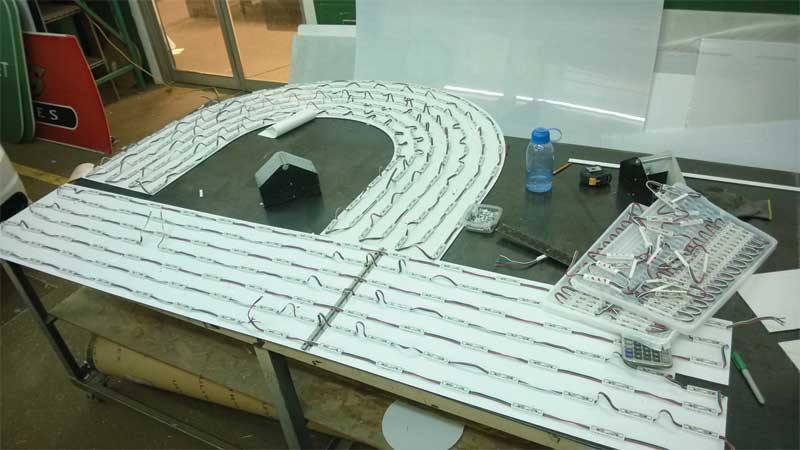

EK: In total, there were 1435 individual mods incorporated into the sign. The ‘W’ alone required 281—more than any of the other channel letters.

In regards to planning the lighting, there was a lot to consider. As the installation was colour-changing, one of the project requirements was wireless LED control. This capability allowed the sign to be illuminated at a moment’s notice and let users change the sign’s colour depending on the event or season.

SMC: Did you encounter any specific challenges during the project’s planning, design, or construction?

EK: All of our shop drawings were certified by an engineer to ensure the structure would be solid and able to safely withstand visitors playing on and around the sign. We had to be sure it would stand the test of time and survive the crazy Winnipeg weather.

The biggest challenge, however, was having all eight of the enormous letters in the shop at the same time. Moving each one around the shop through various stages of production took a lot of effort. It was like a serious game of Tetris!

SMC: What does the future hold for SRS?

EK: As we gear up to celebrate the shop’s 20th anniversary, the future is as bright as ever. The staff is excited to be part of such interesting projects and SRS plans to maintain consistent growth and retain its employees by providing a safe and happy workplace.

For more information, visit www.srssigns.ca[4].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/30-Truck-Group-Photo_crop.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/28-Thats-A-Wrap.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/20170930_215550.jpg

- www.srssigns.ca: http://srssigns.ca/

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/2-Steel-Structure.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/4-Strucutre-Housing-Combined-Jeff.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/9-Bruce-Sanding.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/11-Moving-Cont.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/13-EN-Painted.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/15-P-LED-Panel.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/19-Ephram-Jeff-wiring-the-G-and-P.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/23-W-Illuminated.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/12/26-Craning-W-for-Final-Installation.jpg

Source URL: https://www.signmedia.ca/talking-shop-with-srs-signs-services/

[5]

[5] [6]

[6] [7]

[7] [8]

[8] [9]

[9] [10]

[10] [11]

[11] [12]

[12] [13]

[13]