By Francis S. Lestingi

No matter how technological the sign industry becomes, there will still be magic in the artistry of hand-crafting wood. Most of these signs are either wall-mounted (i.e. fascia signs) or post-mounted, each requiring its own installation techniques.

Facing fascia

With traditional fascia signs that are hand-carved from mahogany or other wood panels and then gold-leafed, it is recommended to use ‘hidden’ installation hardware, so as to avoid piercing or puncturing these intricate panels with any drilling or perforations.

Two methods for accomplishing this are a French cleat and a hanger bolt. Some fascia installations will use both techniques because they involve multiple panels.

French cleat

The French cleat is suitable when the panel is heavy and large. To prepare it, a table saw is first used to cut a 51 x 203 x 203-mm (2 x 8 x 8-in.) pressure-treated board down the middle at a 45-degree angle (see Figure 1). The half with the ‘down’ angle is attached to the back of the sign panel with deck screws. The other half is fastened to the wall, such that the ‘up’ angle is ready to receive the interlocking ‘down’ angle (Figure 2).

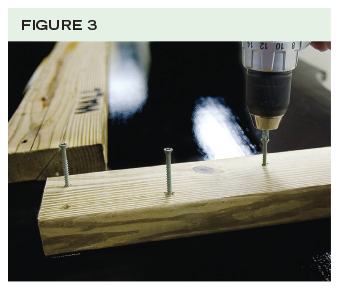

To stabilize the panel, spacers are attached to each side, using pressure-treated 51 x 102-mm (2 x 4-in.) lumber (Figure 3). The cleat and spacers should provide an attractive standoff for the panel of approximately 38 mm (1.5 in.).

Before securing the cleat to the wall, however, it must be prepared by pre-drilling pilot holes and counter-sinking to accommodate the fasteners. When installing a sign on a brick wall, expansion bolts should be used, which are different from hanger bolts.

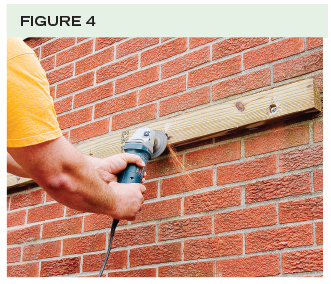

After the appropriate measurements are taken, the cleat should be secured to the wall by using a power hammer drill. As the expansion bolts are ratcheted into the wall, they will expand along the shaft and thus tightly grip onto the brick. While the shaft is expanding, the threaded posts progress outward; they must be levelled off with a grinder (Figure 4).

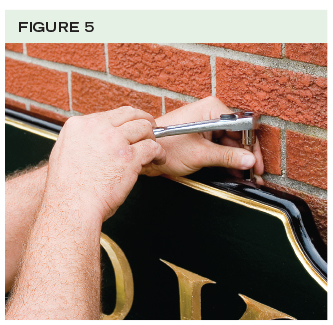

Once this is done, the wall cleat is ready to accept the sign panel cleat. As a final step, the two cleats are fastened together by ratcheting lag screws into pre-drilled holes (Figure 5).

Some people have interest in doing wooden work at home by their own. Table saw is the best thing for them. Through this, people can do small work on their own.

Sharp Reviews