How long will it last?

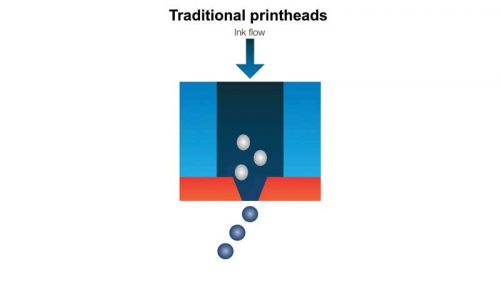

Figure 1 shows the inner workings of traditional printheads where the actuator chamber has one ink inlet, and the ink flows straight from the inlet to the nozzle.

The expected life of a printhead depends on the device type and how it is used and maintained. Superior inks along with best maintenance practices ensure a longer life.

In fact, industrial printheads can last for several years if they are well cared for.

That said, some printheads may fail when producing wide-format graphics not because they have worn out, but due to poor operation including misuse, low quality inks, and poor maintenance. Most device breakdowns are due to ink clogging in the nozzle (either through drying [solvent] or curing [UV]), or damage to the nozzle plate caused by head strikes on the substrate, and wiping the printhead with a dirty rag. Printhead nozzles are less than half the diameter of the width of a single strand of human hair, so it does not take much to block them.

That said, superior inks can significantly extend the life of a printhead; they jet better and prevent blockages. Print-service providers (PSPs) must use a manufacturer-approved ink, follow recommended maintenance procedures, and take anti-static precautions when handling replacement heads.

In some cases, the printhead’s architecture helps to prolong the life of the device by providing a long ‘throw distance.’ The design also increases stability of the actuator and robustness of the printhead. Combined with an optimized nozzle guard to support automated maintenance routines, a printhead can perform well, even in harsh environments.

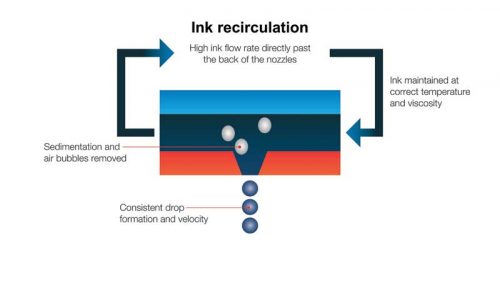

Figure 2 shows how ink recirculation technology works. While many printheads today incorporate recirculation, what is more unique is the technology that recirculates ink directly behind the nozzles, along with a high flowrate.

Another way of ensuring a longer printhead life is by using the ink recirculation technique. The ink flows directly behind the nozzles during non-printing (idle) periods, which helps clear any air bubbles and removes contamination, ensuring the nozzles are not permanently blocked. The recirculation also manages pressure variations across the printhead when printing in multiple orientations, such as vertically (skyscaper mode), delivering

high drop volume as well as accurate drop placement for superior print quality, high speed, and reliability.

Printhead manufacturers sell heads to original equipment manufacturers (OEMs), who sell them to the dealer and, ultimately, to the end-user. The former typically warrant their products against defects in manufacture to OEMs, provided the heads are jetting an approved ink. This warranty is typically passed on to the customer.

Replacing the printhead often depends upon the mechanics of the printer. The alignment of the device is critical, and manufacturers have techniques to properly replace printheads in the carriage.

Many end-users never consider the most important component of a wide-format printer is the printhead. And, as it turns out, there is much customers do not see or consider that contributes not only to the device’s speed

and quality, but also to its longevity—and ultimately, the print provider’s bottom line.

Jason Remnant is the head of business development at Xaar. He started as a printhead development engineer at the company in 1996 and has spent the majority of his professional career in inkjet printing. He then progressed to international sales and original equipment manufacturer (OEM) technical support, through to product management. Subsequent positions have developed Remnant’s expertise in the full range of thermal, piezo, and continuous inkjet technologies. He can be reached via email at jason.remnant@xaar.com.