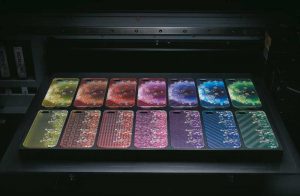

Many popular promotional products are becoming easier to print on directly using ultraviolet (UV) printers. Photos courtesy Roland DGA

By Ginny Mumm

Looking to print on something small and cylindrical, such as a pen or drinkware? Perhaps something large and flat, such as a canvas or a billboard? How about a golf ball or a tennis shoe? Today’s ultraviolet (UV) printers can produce all of these applications and more.

According to a recent report from Verified Market Research, the worldwide UV/LED printer market was valued at US$338 million (C$423 million) in 2021, and is expected to reach almost US$759 million (C$999 million) by 2030, with a compound annual growth rate (CAGR) of 9.5 per cent.1 As a result, some remarkable advances in UV printers, print accessories, inks, and software have taken place over the past few years.

For some first-hand insight on the market’s progress, we spoke with Kitt Jones, co-creation product manager at Roland DGA, about what new directions UV printing is taking and how print service providers (PSPs) and manufacturers are responding to the increased demand for unique applications from customers.

Today’s applications can also provide a range of unique textures and dimensional effects which add value to custom products.

How do you think the market for UV printing is doing post-pandemic?

Kitt Jones (KJ): Overall, the UV printing market remains strong and continues to grow. More businesses are incorporating it to add value and appeal to an ever-widening variety of consumers, including at-home businesses and startups, as well as larger shops looking to expand their lineups. Recently, we’ve even seen UV printing expand beyond the core signage and object decoration markets.

One trend to watch is the increased use of UV printing as an in-house process for mid-level industrial manufacturers. These companies are interested in acquiring the capability to print on their parts or finished products, partially in reaction to the supply chain woes experienced during the pandemic. They want to control their own destiny as much as possible, and having this print capability allows them to be more self-sufficient. Additionally, they save time and money by not having to ship their product somewhere else for printing.

The major growth of e-commerce businesses has led to increased sales of smaller UV printers. These benchtop or desktop printers are perfect for object printing and on-demand production. Smaller units had been doing well in recent years with the home-based and small business markets, and those markets continue to grow. Once these smaller businesses begin to pick up steam, they tend to upgrade to larger flatbed, roll-to-roll, or hybrid belt-driven UV printers.

The Canadian market is experiencing growth similar to that in the U.S. and is very receptive to the wider range of UV printer options. There is increasing demand for personalization and customization applications, and we’re starting to see the demand grow in manufacturing and other non-core markets as well.