The ultra-versatility of ultraviolet

by carly_mchugh | 6 September 2023 11:15 am

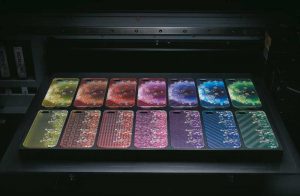

[1]

[1]Many popular promotional products are becoming easier to print on directly using ultraviolet (UV) printers. Photos courtesy Roland DGA

By Ginny Mumm

Looking to print on something small and cylindrical, such as a pen or drinkware? Perhaps something large and flat, such as a canvas or a billboard? How about a golf ball or a tennis shoe? Today’s ultraviolet (UV) printers can produce all of these applications and more.

According to a recent report from Verified Market Research, the worldwide UV/LED printer market was valued at US$338 million (C$423 million) in 2021, and is expected to reach almost US$759 million (C$999 million) by 2030, with a compound annual growth rate (CAGR) of 9.5 per cent.1 As a result, some remarkable advances in UV printers, print accessories, inks, and software have taken place over the past few years.

For some first-hand insight on the market’s progress, we spoke with Kitt Jones, co-creation product manager at Roland DGA, about what new directions UV printing is taking and how print service providers (PSPs) and manufacturers are responding to the increased demand for unique applications from customers.

[2]

[2]Today’s applications can also provide a range of unique textures and dimensional effects which add value to custom products.

How do you think the market for UV printing is doing post-pandemic?

Kitt Jones (KJ): Overall, the UV printing market remains strong and continues to grow. More businesses are incorporating it to add value and appeal to an ever-widening variety of consumers, including at-home businesses and startups, as well as larger shops looking to expand their lineups. Recently, we’ve even seen UV printing expand beyond the core signage and object decoration markets.

One trend to watch is the increased use of UV printing as an in-house process for mid-level industrial manufacturers. These companies are interested in acquiring the capability to print on their parts or finished products, partially in reaction to the supply chain woes experienced during the pandemic. They want to control their own destiny as much as possible, and having this print capability allows them to be more self-sufficient. Additionally, they save time and money by not having to ship their product somewhere else for printing.

The major growth of e-commerce businesses has led to increased sales of smaller UV printers. These benchtop or desktop printers are perfect for object printing and on-demand production. Smaller units had been doing well in recent years with the home-based and small business markets, and those markets continue to grow. Once these smaller businesses begin to pick up steam, they tend to upgrade to larger flatbed, roll-to-roll, or hybrid belt-driven UV printers.

The Canadian market is experiencing growth similar to that in the U.S. and is very receptive to the wider range of UV printer options. There is increasing demand for personalization and customization applications, and we’re starting to see the demand grow in manufacturing and other non-core markets as well.

[3]

[3]Manufacturers are developing a range of accessories to enable fast and easy printing on 3D objects such as golf balls.

What are some of the main factors driving the demand for UV printing today?

KJ: The biggest driver for UV printing demand continues to be consumer trends towards personalization and customization. UV printing allows operators to print on almost any substrate. Though not every substrate or media is perfect for printing on, many pre-manufactured products can be customized to add value. Additionally, UV printers can produce one-offs, or a series of custom items, each with a different graphic. These on-demand orders, typically placed online or via retail walk-in, are produced in a smooth and efficient workflow.

The ability to customize and decorate on-demand, and in whatever quantity is needed, provides an incredible level of flexibility that makes digital UV printing an appealing and cost-effective solution for PSPs and their customers.

How have manufacturers responded to this demand? What are some of the recent innovations in print devices?

KJ: We’re seeing the introduction of UV devices with faster print speeds and better-quality output. Some roll-fed UV printers combine the benefits of high-definition image quality and increased productivity with the flexibility and convenience of integrated print and cut. Additionally, next-generation printers allow for a wider, more customizable ink gamut, and UV flatbeds are deeper and larger than ever, which means they can accommodate an even greater range of printable items.

Over the past four or five years, manufacturers have been filling in the gaps in printer sizes, offering a range of printers from desktop versions all the way up to high-productivity flatbeds, which can handle 1.2- x 2.4-m

(4- x 8-ft) media boards with edge-to-edge printing. Having more printer size options allows users to try out UV printing with smaller models, and, as their businesses grow, upgrade the size and speed of their devices as needed. We continue to see very strong sales of benchtop UV flatbed printers to clients in the small office/home office (SOHO) space.

How would you describe the advancements in UV inks over recent years?

[4]

[4]UV inks can be applied to a wide variety of media and 3D objects, including leather, glass, vinyl, canvas, and wood.

KJ: Manufacturers have been able to advance UV inks in three different areas: developing an expanded colour gamut, for improved print quality and colour matching; providing an array of ink formulations designed for specific applications; and offering a variety of configurations for each user’s needs.

The expanded gamut of UV inks offers deep, rich colour options for standard UV printing. Different ink formulations also enable optimal production for certain applications. For instance, “shrink ink” is particularly well suited for labels and flexible packaging. Some inks are also Proposition 65 and Consumer Product Safety Improvement Act (CPSIA) compliant, making them safer to use on products for children or pets, or in medical settings.

Configuration options have also expanded. For example, some UV flatbeds and printer/cutters are available with a variety of different ink configurations. This added flexibility allows users to configure their inks in the best way possible for their respective business needs and applications. Further, today’s UV inks are generally more durable, in the sense they offer improved adhesion and scratch resistance. This allows for a greater range of applications, as users can print on a vast array of substrates and products which endure a variety of environmental conditions.

[5]

[5]Durable, precisely applied colour on a variety of surfaces is a hallmark of UV printing.

What about the new printer accessories becoming available to users?

KJ: Manufacturers are developing printing accessories that are opening up new markets, such as attachments which allow printing on specific types of 3D objects. For example, rotary rack accessories are now available to enable printing on cylindrical objects. Users of benchtop UV printers love the ease of use and effectiveness of these devices, which has resulted in the expansion of these offerings to include models for 762-mm (30-in.) and 1,625.6-mm (64-in.) flatbeds.

These larger accessories are easy to use, and with the expanded format, users have the flexibility to either print one large product or multiple small products at once. They also allow users to add unique textures, gloss, and other enhancements, as well as vibrant cyan, magenta, yellow, and black (CMYK) graphics. These accessories are extremely versatile and robust, which makes them perfect for small businesses, print professionals, and even industrial manufacturers.

Additionally, there is another accessory which allows 360-degree printing on golf balls and other small balls. UV printer users continue to bring forward more creative ideas for applications, and manufacturers will continue to develop new and innovative accessories to help them achieve their goals.

What other innovations have you seen in the marketplace?

KJ: Manufacturers are also coming up with creative solutions to apply UV prints to objects with non-standard surfaces, such as rims or edges. For example, a print can be transferred directly to an irregularly shaped object or surface, such as the interior of a bowl or the surface of a rimmed plate. These graphic transfers are extremely durable and can withstand washing. They also allow users to employ all the same gloss and texture effects as they would with a direct-to-object UV printing application.

What do you see ahead for the UV printing market?

KJ: Continued evolution and continued innovation. Today’s roll-to-roll printers lay down high-quality prints faster than ever, and we anticipate speeds will continue to improve. We’ll also see further evolution in ink formulations, with additional colours such as fluorescents and metallics coming into use.

Additionally, the lower costs of today’s UV printers, coupled with a post-pandemic shift to local or in-house manufacturing, has led to an increase in the use of UV printing by industrial manufacturers and other non-core markets. In turn, printer manufacturers are creating insightful solutions such as individualized training and support programs.

Increasing demand for UV-printed products means manufacturers will continue to work to meet the needs of customers with advanced print technology, software, inks, and print accessories. Providing a range of printer sizes and ink configurations will further customize the user experience and enable users to satisfy a wider variety of print requirements. Finally, print manufacturers will continue to find new ways to support businesses that are incorporating UV printing, through online and in-person training.

Notes

1 For more information, visit https://www.verifiedmarketresearch.com/product/uv-led-printers-market.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.

- [Image]: https://www.signmedia.ca/wp-content/uploads/2023/09/Bottle-Openers-Roland-DG_SM.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2023/09/VersaUV-Applications-.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2023/09/Golf-Balls-Roland-DG_SM.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2023/09/UV-Handbag-Leather-Print.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2023/09/UV-print-personalised-bottle_SM.jpg

Source URL: https://www.signmedia.ca/the-ultra-versatility-of-ultraviolet/