The versatility of UV LED printers

by all | 19 February 2019 4:45 pm

By Michael Perrelli

[1]

[1]

Inquisitive people frequently follow an answer to an inquiry with a seemingly simple question: ‘why?’ While this may be the simplest of questions with a clear request for more details on the topic at hand, this is nonetheless one word capable of yielding big answers.

When industry professionals exhibit ultraviolet (UV) light-emitting diode (LED) printers at trade shows or discuss the technology when leading an educational seminar, visitors often ask questions such as, ‘why are these so popular?’ or ‘why are people investing in this?’ While those familiar with the technology can answer questions such as these with long-winded strategies and return on investment (ROI) examples for nearly every industry, it might instead be beneficial to focus on the awesome applications made possible with this equipment and why it is so popular in sign shops.

A quick overview

[2]

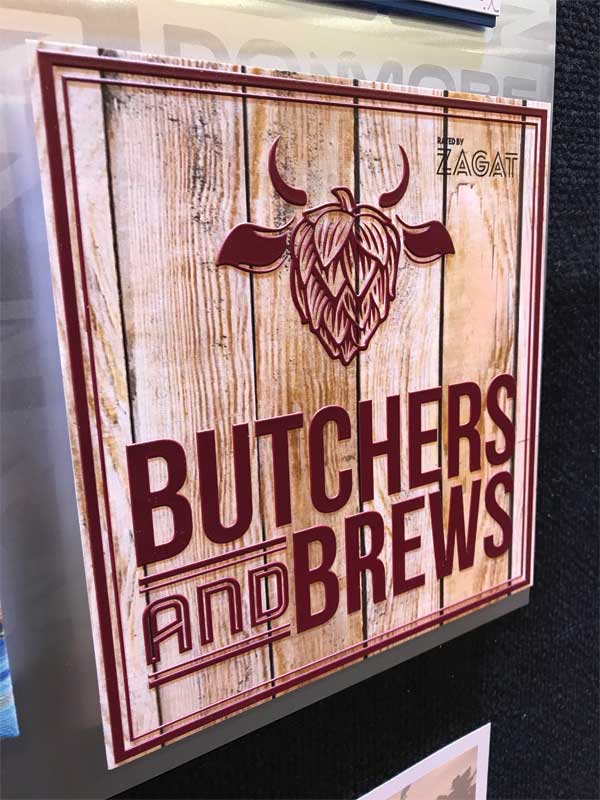

[2]The wood grain background on this Butchers and Brews sign was digitally printed onto generic aluminum sheet stock.

UV LED printers use special UV-curable ink. This ink is jetted through a print head and then immediately cured on the material’s surface when passed over by the UV LED lamp (attached to the print head). The print does not permeate the surface of the material, is dry upon completion, resists many harsh chemicals, and can be applied to many different substrates.

Most small- and mid-sized format options have printable areas that range can between 279 x 406 mm (11 x 16 in.) and 607 x 1219 mm (24 x 48 in.). Further, these units have varying Z-axis (or height clearances), ranging from 50.8 to 381 mm (2 to 15 in.). There are options available for companies of all sizes, regardless of footprint, budget, or process.

Versatility abound

UV printers are among the most versatile pieces of signmaking equipment on the market today. Custom acrylic awards, braille signage, plaques, phone cases, wood signs, water bottles, and even T-shirts can be created using a single UV printer.

While not all businesses require this array of printing capability, using the equipment for a singular application is, of course, equally effective; however, operators should still be made aware of the levels of versatility at their disposal. There are many single-person operations that print all of the products listed above as a side business, as well as full-scale, multi-location sign companies that print braille signage on multiple units for two or three shifts a day.

When analyzing the versatility of this inkjet technology, printed samples help tell the story and serve as one of the main pieces of the purchasing puzzle. As such, signmakers should ensure they understand the process for replicating the samples received (i.e. was an adhesion promoter used? Did print settings need to be modified in any way?). Further, when purchasing a UV LED printer, signmakers should be sure to ask about print times and ink costs. This detailed information goes a long way in helping to plan print process, flow, and implementation.

Signs pointing forward

[3]

[3]Signmakers can use the tonal quality of an image to create detailed textured effects where the brushstrokes can be seen and felt.

Aside from versatility, what are the main attractions for why a sign shop should add this digital, full-colour capability to its in-house technology?

Business growth and enhanced profitability are the consistent main objective for any company. As such, more and more sign shops are looking to UV printers as a strategy to satisfy potential voids in their product portfolios (new products), streamline labourious workflow (efficiencies), or complement monochromatic technology (enhance current offerings).

Add colour and meet customer demand

Digitally printing photo-quality, full-colour graphics and/or backgrounds on a range of materials is not something offered by every sign shop. Some might rotary engrave and/or sublimate, but full colour capacity is not always present.

UV-formulated cyan, magenta, yellow, and black (CMYK) inks on their own tend to be somewhat transparent when printed, appearing similar to stained glass. Using white ink as a base layer gives them the punch needed to stand out. As such, most models of UV printers on the market today include white ink within the standard CMYK set. An opaque white ink is vital for printing on dark substrates and achieving optimal colour saturation on these types of materials.

This colour capability can be beneficial in many ways. Say, for instance, a shop has an order for 50 signs that require a woodgrain background. With a UV printer, an operator is able to print every element in-house rather than pay extra for foiled or painted sheet stock; the woodgrain can be printed on the second surface of an acrylic substrate and then the wayfinding, text, or logos can be printed on the front. Signmakers can save even more time if they print it all on a white substrate in a single pass.

Further, utilizing a digital process requires minimal set-up for a job; signmakers simply set their artwork, load the material, hit ‘print,’ and let the machine do the work. The sign will be ready for mounting or further fabricating the moment it comes off the machine.

[4]

[4]Many small-format ultraviolet (UV) light-emitting diode (LED) printer options can fit within a small footprint or area within a shop. This model, complete with a 305 by 610 mm (12 by 24 in.) print area, can be housed on a 0.6 by 1.2 m (2 by 4 ft) work bench.

From a business perspective, the chances are that the same customer who ordered 50 signs will purchase other printed items as well (e.g. golf balls, water bottles, personalized awards), which ties back to the versatility aspect noted earlier. Keep the UV printer running—it is easy for a sign shop to switch between products and expand its offerings with a full-colour capability.

Texture effects can be seen, too

With a UV printer, designing and printing signs with textured elements that can be felt and seen is easy to achieve and can create a remarkable effect. Imagine, for example, printing a sign for a batting cage that has a baseball with raised laces, able to be seen and felt. This element immediately enhances the value of the piece.

UV inkjet technology allows for texture effects to be printed in one of two ways. The first method is to print a certain area or element with multiple clear ink passes, which achieves a raised effect, and then cover the texture with a full-colour print. A faster and more economical method, however, is to use a printer capable of controlling the amount of ink that is dispensed in a single pass, rather than running multiple passes to put down clear, white, and colour. Not only does this method save time, it also allows operators to use the tonal quality of the image to create detailed textured effects.

Braille and tactile element opportunity

[5]

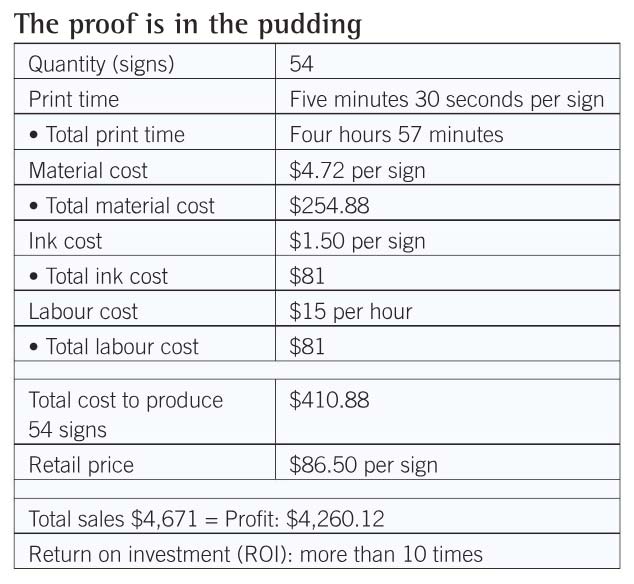

[5]An example of how a sign shop can profit from using ultraviolet (UV) light-emitting diode (LED) printers. (Figures are in U.S. dollars.)

Though accessibility codes in Canada are not regulated at a federal level, provinces and local municipalities have outlined standards and regulations (e.g. the Accessibility for Ontarians with Disabilities Act [AODA]) in regards to braille and accessibility signage, especially when installed in government, commercial, and community facilities.

Further, guidelines outlined by the Canadian Standards Association (CSA) and the Americans with Disabilities Act (ADA) in the U.S. have been used as a model for many local accessibility codes within Canada. These requirements continue to drive the demand for compliant signage, equating to significant opportunity for sign shops.

Using a UV printer to create accessibility signage—complete with pictogram (if needed), text, and braille dots—is more efficient and profitable than traditional methods of printing. Signmakers are able to significantly reduce production time, while simultaneously minimizing production cost and increasing profit margins.

There are a few simple steps to printing these signs:

- Create or import a braille-compliant sign design

- Send the file to the raster image processor (RIP)

- Load the substrate and print.

The versatility of UV LED technology increases the services a sign shop can offer its customers. These printers are large profit margin products and should be utilized.

Logical progression

When researching UV LED inkjet technology, sign shop professionals should prioritize education and samples, as well as ask questions to help define and distinguish the potential benefits as they relate to the specific needs of a company.

UV printers—both small- and mid-sized options—can help to significantly grow a business through added opportunity. For many in the industry, this technology has already established itself as the next logical step in growth.

Michael Perrelli is the marketing manager for Direct Color Systems (DCS), where he manages the company’s marketing activities, content, communications, and strategies. Perrelli also oversees the in-house sample production department and domestic trade show logistics. He can be reached via e-mail at michael.perrelli@directcolorsystems.com[6].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/DCS-Close-Up-ADA-Braille-Acrylic-Signs.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/Butchers.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/TEXTURE.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/1800z_empty_bed.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/02/graph.jpg

- michael.perrelli@directcolorsystems.com: mailto:michael.perrelli@directcolorsystems.com

Source URL: https://www.signmedia.ca/the-versatility-of-uv-led-printers/