Adding a new dimension to traditional channel letters with 3D printing

by | 22 March 2019 10:48 am

[1]

[1]By Matan Weinstein

Whether one is selling a product or service, it has never been harder to attract the attention of the target audience than it is today. According to a recent Forbes article, digital marketing experts believe the average person is exposed to between 4000 and 10,000 adverts every day. With all the many brands and different messages bombarding one’s life, it is not surprising that people have learnt to tune out from the majority of them. However, one marketing medium that remains hard to ignore is channel letters (also known as built-up letters). This illuminated signage, used to display a brand name or logo on the side of a building, in a shopping mall, or at a trade show, continues to help companies stand out from the crowd and attract customers.

Endless creative possibilities

So, how can brands up their game when it comes to ensuring signage is creative and effective? Traditional production methods (using acrylic/aluminum sheets or thermoforming) for complex signs can only offer so much. Basing the design on 2D graphics that are simply protruded by 90 degrees means texture, design, angles, and geometries are limited with regards to conceptualization and production capabilities. In addition, it is a time-consuming and predominantly manual process to create channel letters using these methods, which can negatively impact costs and delivery times. As such, brands are understandably reluctant to increase the complexity of a design.

That said, there is light at the end of the tunnel—large-format 3D printing technology.

[2]

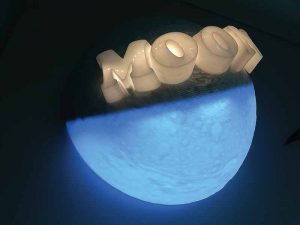

[2]By creating a design file in 3D from the start, all aspects of the letters can be included in the design process. This means the creative possibilities are endless. Brands can incorporate unusual shapes, curves, different angles, and side textures and need not produce one letter at a time or letters at all for that matter. The flexibility and freedom of this printing process enables users to produce cursive words, a logo, or graphic elements of a logo, such as a teddy bear, globe, or coffee cup. Products and mascots can be printed as separate, eye-catching signs or incorporated within the letters. Additional eye-catching features, such as light-emitting diode (LED) lighting or video mapping, can easily be added to 3D printed channel letters for enhanced visual impact. One starts to see the tangible benefits 3D printing delivers to companies when evaluating the challenges signmakers using aluminum endure while creating letters (like ‘O’) with an empty cavity.

[3]

[3]Reduced production errors

Using 3D printing technology, complex, creative signs can be created at a significantly higher speed than traditional methods. Other than reduced time and manual intervention, a 3D printing solution designed to produce large-format visual applications can also create attention-grabbing retail signage, high-impact vehicle wraps, and crowd-stopping event and exhibition displays. Those 3D printing solutions that offer dual printheads can also print two models simultaneously, making production even more cost-effective and also lowering the cost for the end customer.

Reducing the manual elements of the production process also diminishes production errors. For example, by amending the design on screen, such as adjusting the curve of a letter before sending it to the 3D printer, the user can eliminate any errors and avoid costly iterations altogether.

The way forward

[4]

[4]Looking at the clear advantages of 3D printing, it is hardly surprising why signmakers across varied markets are choosing to expand their business offering by adding this equipment as part of their production capabilities. Large-format 3D printing solutions is the only technology available that allows signmakers to take this step. These printers enable print providers to produce innovative, versatile, 3D-printed applications for the advertising, retail, entertainment, events, exhibitions, and interior design industries. Today, the most significant difference between 3D printing solutions and traditional methods is the ability to ensure fewer constraints in terms of the print output size. Print providers and brands can creatively think big insofar as sign and display production. When it comes to breaking new ground with creative, cost-effective, large-scale signage, such as channel letters, one can easily forgo traditional production methods as large-format 3D printing is the way forward.

Matan Weinstein is an expert in 3D printing technologies, including Massivit 3D large-format gel dispensing printing solutions, SLS, SLA, DLP, and FDM. Weinstein is also a seasoned 3D modeler for retail, prototyping, and architecture applications. For more information, contact info@massivit.com[5].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/03/Opener.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/03/1.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/03/2.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2019/03/Applications-book-pics-41-copy.jpg

- info@massivit.com: mailto:info@massivit.com

Source URL: https://www.signmedia.ca/the-writing-is-on-the-wall/