Tips & tricks for wrapping transit vehicles

Art Gallery of Ontario. Photos courtesy Pattison Outdoor

By Estella Tolentino-Cooke

Vehicle wraps come in many shapes and sizes. For those clients looking for maximum visibility, there is no greater platform than a moving billboard such as a bus or train. For signmakers involved in this segment of the industry, huge vehicle wraps come with their own unique set of challenges. One could even say, they are not for the faint of heart. This article offers some sage advice on how one can post, stick, and wrap just about any transit vehicle.

Vinyl

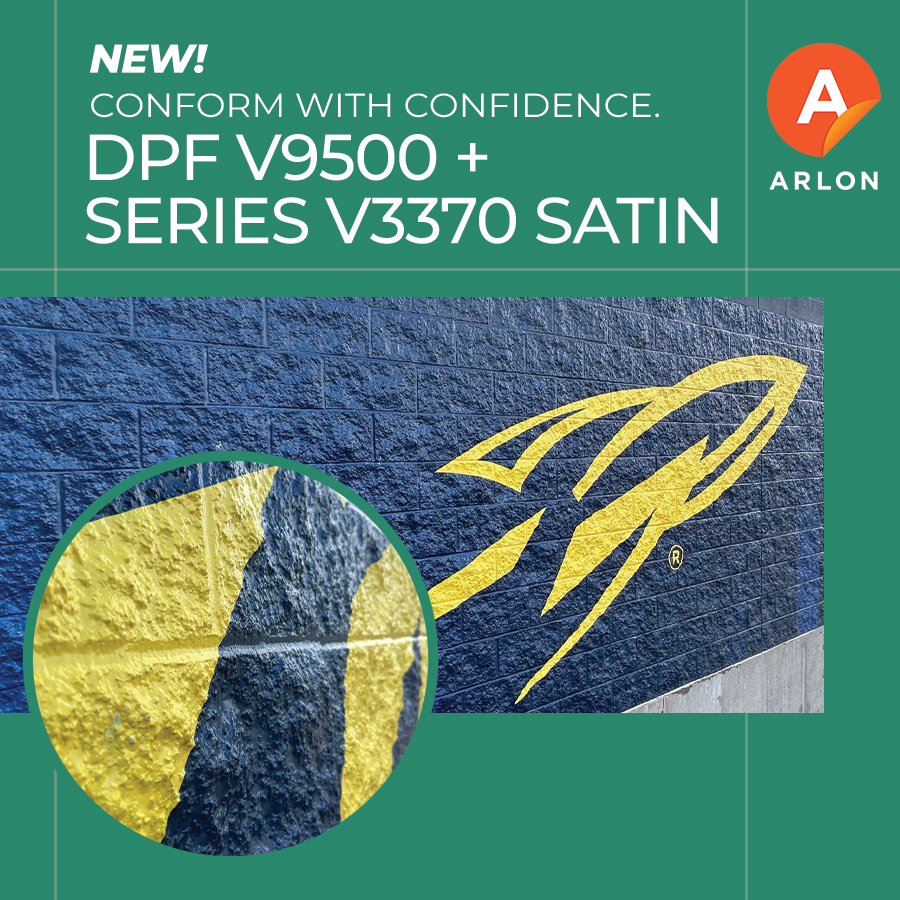

There is a staggering variety of vinyl products available and combing through every provider’s booklet can be cumbersome. However, there are some product specifications to consider when selecting the right adhesive for the job, such as how well the vinyl conforms to a surface, how cleanly the material can be removed, and ensuring the vinyl product doesn’t leave behind any glue or residue.

Large transit and fleet vehicles have all kinds of bumps, corners, gaskets, and other anomalies so the vinyl needs to be able to stretch, cover, and conform to these irregular surfaces. When covering windows, one should use a perforated vinyl with laminate. Certain markets have different requirements for the size of the perforated holes. Most window graphics are either 60/40 or 70/30, meaning that 60 or 70 per cent of the window is covered by vinyl, while still offering 40 or 30 per cent visibility from inside. When it comes to the rubber gaskets that surround bus and train windows, it is best to err on the side of caution and choose not to cover them. After going through the bus wash, these linings often come out the other end holding water, which can easily lead to moisture getting under the wrap and start lifting the vinyl.

Not all bus barns are the same; there are many that may not allow for installers to work in pristine conditions. That is why it is important to find stock that can also be applied in less-than-ideal conditions and capable of weathering a bit of a beating, because not all buses are housed indoors. You won’t always be working within the right temperatures, but the vinyl still needs to apply and hold up.

Another factor to consider when selecting a new substrate is peel adhesion, which refers to how well the material sticks and removes. Some installers work with vinyl that has a peel adhesion of less than 2 lbs. per inch and, where possible, ones that are under 1 lb. per inch. However, that limits several viable options.

A preferred stock for transit vinyl is the 3M 3500 Controltac—a calendared vinyl with a lot of options for many applications. It is a 4-mm (.2-in.) white opaque vinyl with a matte finish. This material features air channels to help release air bubbles during application. It can be easily removed without leaving behind residue, and it does not require heat or chemicals to pull away. It can also slide and be adjusted easily to help with alignment. This is a perfect option for transit or fleet vehicles. For longer campaigns, one should consider changing out the material at least once a year to prevent it from becoming a more permanent fixture. The longer any vinyl is applied, the tougher it becomes to remove.