Using signmaking tools to create art

by all | 10 May 2018 9:15 am

[1]

[1]Photos courtesy Dave Metituk

By Brian Spiteri

Many signmakers would agree an ideal project involves a careful balance of creativity, freedom and focus. Too much of any one of those components can easily cause a project to run over schedule and over budget. And when municipalities and committees are introduced to the mix, they often add an extra layer of complexity to the logistics, such that creativity can end up being the last priority.

In 2017, the Canada 150 committee for Grande Prairie, Alta., along with a corresponding community foundation, decided to commission and install a special mural. It would combine hundreds of photos taken throughout the year at various Canada 150 celebrations with an original piece from visual artist Robbie Craig of Yellowknife, N.W.T., depicting a bear.

The committee and foundation spent months trying to find a creative way to make this project come together. During a period of frustration, one of the committee members asked Dave Metituk, co-owner of a local Speedpro Signs franchise, if his business could create a mosaic.

Having co-owned his shop for nearly 20 years, Metituk has augmented his innate problem-solving abilities over time with a breadth of skills in production, fabrication, installation and product development. When his 204-m2 (2,200-sf) shop’s production department added a computer numerical control (CNC) router 15 years ago, for example, its in-house fabrication capabilities increased exponentially. Other key equipment includes a vinyl plotter, a flatbed applicator, a 1.4-m (54-in.) wide laminator and two 1.4-m wide ‘eco-solvent’ inkjet printers, along with various hand tools.

Client consultation

Meeting on-site with both the client and the artist was a critically important early step in the process, so Metituk could really understand the space, the artist’s point of view and the importance of the project to the city. The mosaic would be displayed at Theresa Sargent Hall, an open public space attached to the local art gallery and library.

The main challenge was to create a mosaic that would stand the test of time, as it was to remain installed for the foreseeable future, but also complete it before the end of the year, so as to take advantage of the grant funds available to support it.

It can be very difficult for clients to visualize what is possible with today’s signmaking tools and materials. Digital proofing has come a long way in helping to alleviate this issue, but as Metituk proposed multiple layers of images, with different material treatments, the roles of signmaker and artist began to blur at a certain point. Fortunately, he was able to win permission to create the vision as he saw it in his head.

[2]

[2]The mosaic images were mounted to the back side of the tempered glass using a flatbed applicator.

Production

After getting the artist and client to approve his concept, which featured a monotone mosaic of the provided photos in the background and a CNC-routed acrylic reproduction of Craig’s painted artwork as the front surface, the next task was colour selection.

The concept’s colour palette leaned heavily on shades of brown. There were not enough vinyl options in circulation to support all of the necessary hues. Another option would be paint, but instead, Metituk created a wider range of colours by layering vinyl on the face and back of the clear acrylic. When light penetrates the acrylic, it changes the appearance of the colour. Also, many vinyl films show a different shade when they are reversed. The key to making the image really stand out, however, was adding leather-textured wrap material to certain parts of the bear, where it visually made sense.

The process of deciding upon the colours and then determining how to create them through layering and how to construct the bear took about two to three days.

The background was constructed with 8-mm (0.3-in.) thick tempered glass, which was custom-cut to hold the standoffs. The choice of standoffs and anchors was also very important, as they would need to (a) support a significant amount of weight, given the two panels would weigh 54 kg (120 lb) each, and (b) prevent vandals from removing the piece from the wall. As such, in comparison to most gallery art, the installation hardware had to be ‘overdesigned.’ The combination of sign standoffs and high-performance anchors (the same type widely used for hanging large TV screens in home theatre systems) could support approximately 113 kg (250 lb). Also, Metituk modified the standoffs by adding 51-mm (2-in.) spacers made of 6-mm (0.2-in.) thick black acrylic, to distribute the weight over a larger surface area than just the holes.

After importing all of the provided photos for the mosaic and filtering them with a light blue/grey colour, which had test-printed properly, Metituk aligned and trimmed the images to fit in horizontal rows. Overall, almost 600 photos were used.

[3]

[3]Dave Metituk handled the project at his Speedpro Signs shop.

Next, the images were reverse-printed onto ‘etched glass’ vinyl using one of the eco-solvent presses, laminated with white vinyl and mounted to the back side of the tempered glass using the flatbed applicator. The vinyl installation was completed within an hour, with no contamination of the prints and no reprinting needed.

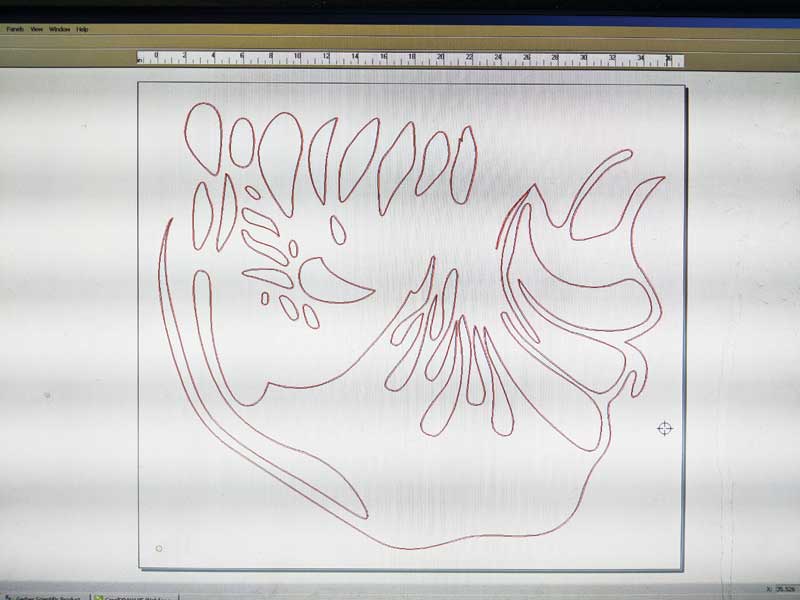

The image of the bear, meanwhile, started out with more than 200 pieces of vector art provided by Craig. Metituk managed to combine these and reduce the number to 134 pieces with no visible differences. The process required attention to the most minute of details, particularly during welding and drilling.

Further, the bear was not simply a flat image when fully assembled. Some of the acrylic components, such as the front shoulder, were thicker than the rest, while others, like the rear foot, were thinner. In this way, the image became more dimensional than it could have been as traditional painting.

Another challenge was figuring out how the configure the layers. The vinyl on the back side of the clear acrylic offered an opportunity for light to play a role in highlighting parts of the bear. By way of example, the bear’s eye was routed halfway through 12-mm (0.5-in.) thick acrylic and painted on the back side, giving it a surreal ‘floating’ effect.

The bear required a variety of thicknesses of acrylic, ranging from 1.5 to 12 mm (0.06 to 0.5 in.). Most of the material was clear, as mentioned, but some portions provided a layer of black as desired to affect the layout, play with the colour tones of some of the vinyl and enhance the effect of viewing the piece from the side.

Ultimately, the 134 pieces of the bear image had to be layered on top of and inside each other. By the end of the project, Metituk could take them apart and put them together just like the pieces of a favourite jigsaw puzzle.

Throughout the process, he took pictures and videos and added them to a shared folder, to which Craig also had access. This way, the artist could see the progress of the piece and provide his feedback along the way. Craig expressed his satisfaction with the attention to detail that was going into the project and said he enjoyed watching it all come together.

Installation

The deadline loomed, as there was to be a public unveiling of the artwork the week after Christmas, with local dignitaries and the public in attendance, at the Montrose Cultural Centre. With this visibility in mind, Metituk handled most of the assembly work in his shop, where many variables—from contaminants to adhesives—could more easily be controlled than in the gallery. He planned to install the bear in nearly-complete form and added three pieces to hide his attachment methods.

To fully raise the heavy glass background panels into place for installation, with their top edge approximately 4.3 m (14 ft) above the ground, Metituk created a jig and attached it to a rented drywall lifter. This way, he could pivot the panels into their precise positions without the risk of dropping them.

The bear was also mounted very deliberately, with a space behind the top of the back. This helped achieve the visual effect of an actual bear’s silver ridge shining in the sunlight.The biggest challenge, however, laid in integrating the components together. No allowances had been made for attaching the acrylic bear to the background, since when the glass was being tempered, no holes could be added to it.

After much consideration, Metituk decided upon plastic mounting pads, as used with dimensional sign letters. He situated these in the space between each glass panel. Then he placed a bolt through the acrylic and into each pad, such that when it was tightened, it would create the tension needed to keep the bear in place. With the assistance of a two-sided adhesive, this technique made installation of the bear on the glass very quick, if still slightly challenging.

In the end, the on-site assembly took approximately 90 minutes. Once the bear was attached to the background, Metituk added the smaller pieces, the vinyl spelling out the piece’s title (‘Subarctic Bear’) and a side panel explaining the project’s meaning. Fittingly for the sesquicentennial nature of the occasion, a final tally of 150 individual pieces came together to form the main mural.

The reveal of the mosaic was well-attended and received. Craig was very happy about the care taken in preserving his artwork, while acknowledging how the increased size and added dimensionality allowed viewers to experience it in a totally new way. The clients, meanwhile, were in awe of the results, as they’d had no concept of how the piece was being created.

Signmakers like Metituk do not always think of themselves as artists, but art comes in all shapes and sizes—and the ability to create it from vinyl and acrylic is perhaps a skill more likely to be found in a signmaker than in a traditional artist.

Brian Spiteri is co-founder of Big Picture Imaging, which prints indoor and outdoor signage, banners, display systems, trade show booths and fleet graphics in Campbellville, Ont. For more information, contact him via e-mail at brian@gobpi.ca[10].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171228_133143.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171223_072837.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171215_083924.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171219_082853.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171219_095111.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171219_144415.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171223_072745.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171222_160853.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2018/05/IMG_20171229_114316.jpg

- brian@gobpi.ca: mailto:brian@gobpi.ca

Source URL: https://www.signmedia.ca/using-signmaking-tools-to-create-art/

[4]

[4] [5]

[5] [6]

[6] [7]

[7] [8]

[8] [9]

[9]