Magnetic receptive systems offer flexible wayfinding design, easily adapting to regulations like accessibility and environmental standards, making them cost-effective and future-proof. Photo © Vector V/bigstockphoto.com

A case for magnetic-receptive systems as a green solution for wayfinding design

By Tori Deetz

Effective wayfinding is crucial in helping people navigate complex environments, whether in a sprawling hospital, a busy airport, or a dynamic retail space. As spaces evolve and adapt to changing needs, so must the signage that guides individuals through them.

Traditional static signage can struggle to meet these demands, but magnetic receptive graphics offer a versatile, forward-thinking solution. From making easy updates and quick installations to ensuring durability and sustainability, magnetic receptive systems present an efficient, flexible approach to designing wayfinding systems. They also provide added value by being easily adaptable to evolving regulations, such as Canada’s accessibility regulations and environmental standards, making them a cost-effective and future-proof option for organizations of all sizes.

It is important to clarify how magnetic-receptive systems differ from traditional magnetic signage. Although the two terms are sometimes used interchangeably, they represent distinct technologies that serve different purposes in wayfinding design.

When crafting magnetic receptive signage, it is essential to consider how various components can be updated independently. Photos courtesy VM-Graphic Systems

What’s the difference?

Traditional magnetic signage involves graphics printed directly onto a flexible sheet magnet that adheres to metal surfaces. This type of signage is widely used for temporary applications, where the entire sign is magnetically attached to a metal surface. While effective, it is limited in scope for larger, more complex wayfinding systems. These signs are often less durable and less sustainable. Since they require a fully metallic surface to adhere to, this can limit their placement in environments where metal base substrates are impractical and costly.

Further, printing graphics on flexible sheet magnets comes with several limitations. Magnets are incompatible with many standard printers, as the thickness and weight of magnetic sheets can cause jams or alignment issues. This often requires specialized printing equipment, which is more expensive and less widely available. Additionally, magnetic sheets are limited in size, typically available only in widths of 304.8-609.6 mm (24-48 in.). This means larger graphics must be pieced together, leading to potential issues with visible seams and misalignment.

Printed sheet magnetics often require non-recyclable materials, including polyvinyl chloride (PVC), for the print surface; the entire sheet magnet must be discarded and replaced, generating more waste. Alternatively, by reducing the need for new materials with each update, magnetic receptive systems contribute to a more sustainable signage solution that aligns with modern environmental goals.

Finally, while flexible magnets can be useful in some settings, they tend to lose strength or wear down with time, especially in high-traffic or outdoor environments.

In contrast, magnetic-receptive signage systems use a flexible sheet magnet as a base instead of the print; the printed layer—the visible signage graphic—is a print film with a ferrous coating on the back. This printed layer is called the magnetic-receptive graphic and is not a magnet. The only magnet in the system is the flexible magnet sheet beneath it. To create wayfinding signage using magnetic receptive graphics, start with a rigid board material such as acrylic, medium-density fibre (MDF), aluminum composite panels (ACM), or eco-composites and adhere it to a flexible sheet magnet base. The graphics are printed on the magnetic-receptive layer that can be placed on this sheet magnet base. This two-part system allows for much greater flexibility regarding placement, size, and modularity. The magnet base stays permanently affixed to the surface, while the magnetic-receptive graphics can be swapped, sleek layered graphic elements such as modular arrows or numbers can be used, and they can be updated quickly and easily. The base itself doesn’t need to be metallic.

This difference is critical when considering long-term, adaptable wayfinding systems. Magnetic-receptive systems allow for modular and interchangeable graphics, providing a more dynamic and sustainable solution. This makes them ideal for spaces needing frequent updates or customization—schools, community centres, hospitals, retail centres, and corporate offices.

Thinking in layers

While diving into the material science behind signage innovation is exciting, we understand that effective wayfinding signage design starts with choosing the right materials and crafting intelligent graphic layouts. Designing magnetic receptive signage requires a shift in mindset that closely resembles the layered approach of graphic design software—like Adobe Photoshop or InDesign. This method encourages designers to think modularly, plan for future updates, and integrate different sign elements seamlessly.

When crafting magnetic receptive signage, it is essential to consider how various components can be updated independently. This often starts with a timeless background that serves as a stable foundation. From there, designers can create additional layers, such as text boxes, arrows, and numbers, printed on magnetic-receptive material. The beauty of this approach lies in the thinness of the magnet-receptive media, which allows the eye to perceive these layers as one cohesive image rather than disjointed elements. This illusion of a seamless design enhances the overall esthetic while maintaining the flexibility to modify individual components as needed.

This layered strategy streamlines the design-and-update process and unlocks greater creative possibilities for signmakers. By thinking in layers, designers can explore various visual styles and solutions, ensuring that wayfinding signage remains dynamic and engaging.

Field-tested: Case studies

Two wayfinding projects come to mind from my time at VM-Graphic Systems over the years. The first was a project in which MagnaMedia and Invisilock magnet materials were used at Bethel Valparaiso Church in Indiana. The sign maker created an elegant wayfinding solution for a space where the use of the rooms frequently changed, sometimes even daily. The text panels could be swapped, and the arrows could be designed within circular layers so that staff could move around to guide visitors to the appropriate locations for that day. This was a sleek, simple, and durable solution to facilitate the wayfinding updates that were required on a continuous basis.

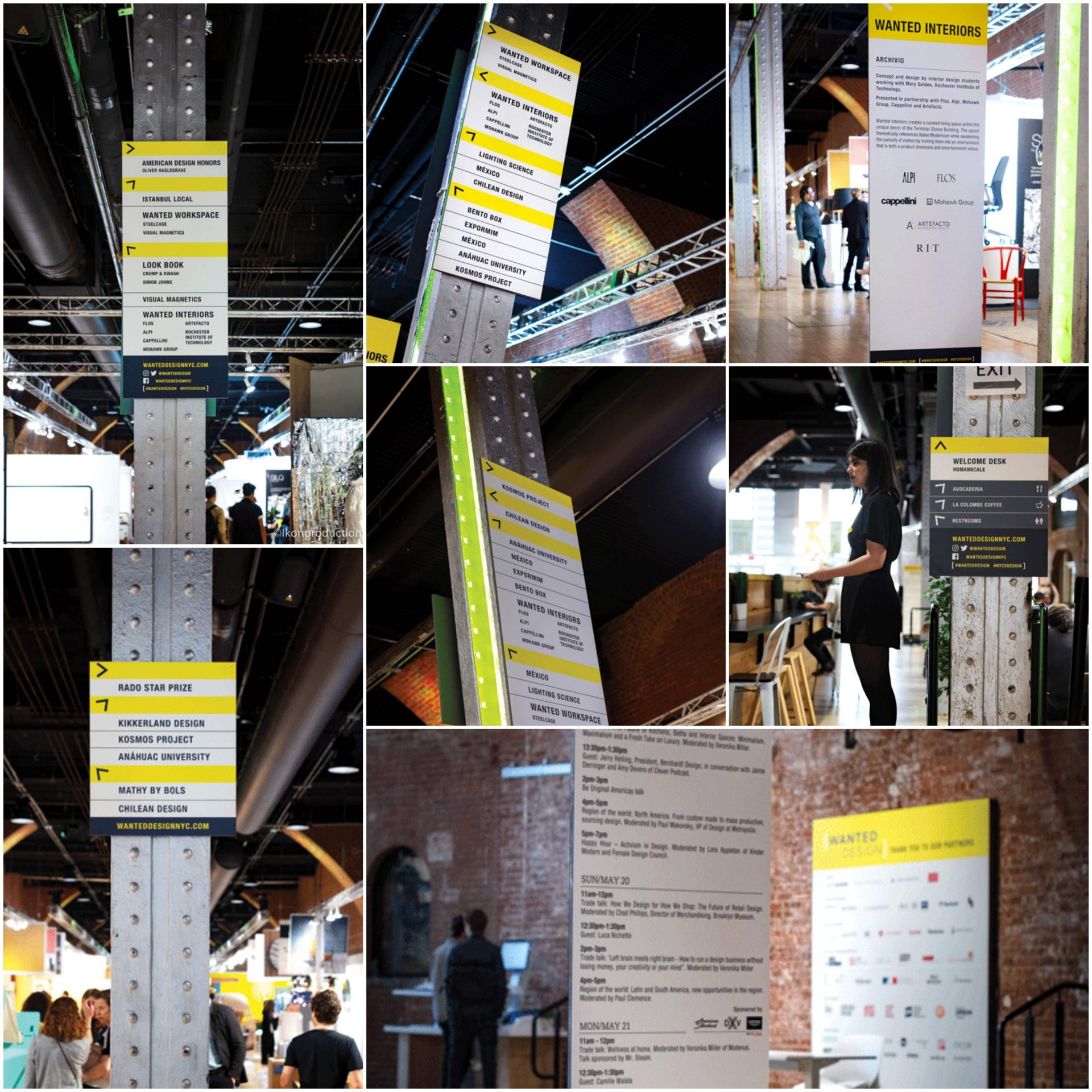

Another application was the magnetic-receptive graphics implemented by WantedDesign, a furniture design exhibition in New York City. The venue often changes, and the exhibitors and sponsors are always different. Their team designed fixtures, such as mounted placards and free-standing kiosks, that could be used yearly, along with generic background graphics in their brand colours. The additional graphic elements, such as sponsor logos, speaker times, and locations of galleries and exhibitors, were printed as fresh layers each year. This was not only in alignment with the elevated sustainability goals of the WantedDesign group but also was an extremely cost-efficient alternative to reproducing the entire signage system every year.

By incorporating modular components that can be easily swapped out, these systems enhance the visitor experience while ensuring compliance with accessibility standards and other regulations.

The eco-pull

While magnetic-receptive systems already stand out as a more sustainable option than many traditional signage solutions, not all magnetic-receptive media products are created equal. Due to several key factors, some magnetic-receptive products score significantly higher on sustainability metrics.

PVC-free materials: One of the most critical sustainability factors is whether a product is free of PVC. PVC has been widely used in signage for its durability and affordability, but its environmental impact is a growing concern. PVC production involves toxic chemicals, and disposal can lead to harmful emissions. As Canada continues implementing stricter regulations on PVC, many magnetic receptive systems have shifted to PVC-free materials, offering a greener alternative without sacrificing performance or durability.

Post-consumer and recycled content: Magnetic-receptive products that incorporate post-consumer recycled content are another way to minimize environmental impact. By using materials that have already been recycled, these products reduce the demand for new raw materials, conserving natural resources and reducing greenhouse gas emissions from the manufacturing process. This can be particularly important in large-scale projects where the quantity of signage materials can add up quickly. Opting for magnetic-receptive systems with a high percentage of post-consumer content allows organizations to contribute to the circular economy.

End-of-life recycling programs: Some manufacturers go a step further by offering end-of-life recycling programs for their magnetic-receptive print films. These programs ensure that when the signage is no longer needed, it can be returned to the manufacturer for responsible recycling or repurposing. Such initiatives reduce the likelihood of the outdated surface layer ending up in landfills. Choosing products from companies with these programs is a proactive way to ensure your wayfinding systems remain sustainable, even at the end of their use. At VM-Graphic Systems, our end-of-life program exemplifies this approach by ensuring the film is separated for recycling. Through a waste-to-energy process, the metal content from the ferrous coating is repurposed in steel production.

As more organizations seek to create adaptable, cost-effective, and environmentally friendly wayfinding solutions, magnetic-receptive systems will play a pivotal role in simplifying navigation across various industries. By incorporating modular components that can be easily swapped out, these systems enhance the visitor experience while ensuring compliance with accessibility standards and environmental regulations, making them the ideal choice for modern wayfinding design.

Tori Deetz is vice president of VM-Graphic Systems, a manufacturer of magnetic-receptive media and the original creator of magnetic-receptive media.