Raised elements

As the photopolymer substrate is processed using UV light and a film negative, the sections exposed to the light harden and become the raised elements of the sign. In one simple step, it is possible to raise not just text and braille dots, but also borders, logos, pictograms, accent bars and other features.

The exposure process allows for these tactile elements to be very fine in detail, including those that would generally be too small or intricate to cut with a laser or computer numerical control (CNC) router.

High-volume production

The process of producing photopolymer signs involves several steps that are compatible with a high-volume workflow. Indeed, one photopolymer processing unit can effectively make more than 400 signs in a single shift.

The more intricate a sign becomes and the larger the number of pieces that are needed for a given job, the more profitable it becomes to use the photopolymer process rather than another method, in part because the material is processed in cycles that can be repeated all day, every day.

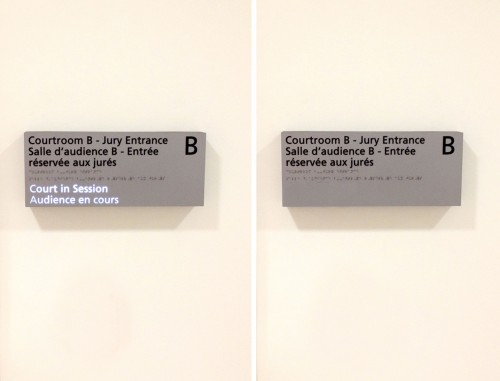

A sign at the Forensic Service and Coroner’s Complex (FSCC) in Toronto uses LEDs to indicate when court is in session. Photo courtesy Acumen Visual Group

Real-world examples

As the demand for accessibility signage has grown in the Canadian market despite the lack of ADA, some sign fabricators have begun to specialize in the use of photopolymer-based substrates. One example is Acumen Visual Group in Markham, Ont., which has worked with organizations, institutions, designers, architects and clients to develop unique accessibility sign systems.

In 2011, Acumen completed a wayfinding project for a downtown Toronto YMCA facility. Branded accessibility signage, fabricated using NovAcryl photopolymers, became a touchpoint for visitors, reinforcing the charitable organization’s spirit of inclusion. The specified photopolymers allowed Acumen to create custom tactile symbols and carry the building’s interior colour scheme across the signs.

Two years later, Acumen finished projects for Ontario’s new Forensic Service and Coroner’s Complex (FSCC) and St. Michael’s Hospital, both in Toronto.

For the FSCC, a public-private partnership (P3) project, Acumen worked with Carillion—a construction and facility management firm—and Webb Zerafa Menkes Housden Partnership (WZMH) Architects to develop both exterior and interior wayfinding signs, including an illuminated ‘court in session’ sign. This sign was made using a clear NovAcryl photopolymer with braille and tactile elements on one surface and the words ‘in session’ paintmasked on the second surface.

Light-emitting diodes (LEDs) were mounted inside the signbox, such that the flip of a switch on the back of the sign allows it to indicate when court is in session by illuminating the paintmasked letters.

Meanwhile, for St. Michael’s Hospital’s newly renamed Donnelly Wing and recently built Li Ka Shing Knowledge Institute, Acumen also handled not only exterior and interior wayfinding signs, but also donor recognition signage and a large-format exterior scrim. Partnering with Hahn Smith Design, the company was able to integrate sign colours as part of a larger overall wayfinding system, including floor graphics, directories, room identification, objects and the built environment, all designed to actively aid in the patient and visitor experience. All of the braille and tactile signs were made with photopolymers and decorated to match the other signs and interior elements.

“Since accessible signage is engaged in both visual and tactile ways, it facilitates a reciprocal relationship,” says Keith Francis, Acumen’s vice-president (VP) of strategic planning and business development. “It is both functionally informative and emotionally significant. There is a greater responsibility to design and fabricate products that serve to bridge the gap.”

Mike Santos is director of sales and marketing for Nova Polymers, which supplies raw materials and equipment for fabricating photopolymer signs. For more information, contact him via e-mail at msantos@novapolymers.com.