Wide-format Graphics: Canvas printing for sign shops

by all | 10 February 2017 10:15 am

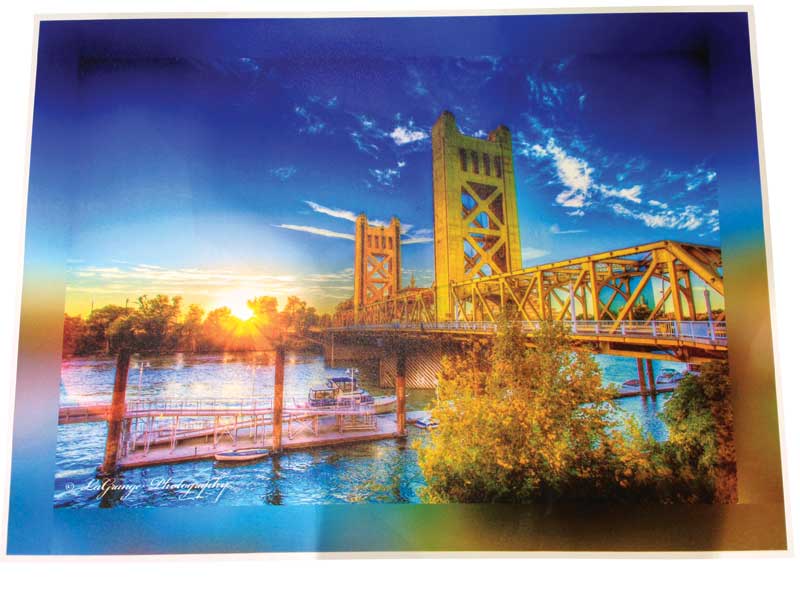

[1]

[1]Photos courtesy LexJet

By Jeff Goetze

Canvas printing has established itself as a growing and profitable segment of the wide-format graphics market. According to InfoTrends, a printing industry research firm, the amount of canvas printed each year will have grown from roughly approximately 46 million m2 (500 million sf) in 2013 to nearly 80 million m2 (860 million sf) by 2018, for a compound annual growth rate (CAGR) of 11.6 per cent.

That rate of growth represents many opportunities across a variety of market segments, from limited-edition fine-art reproductions to corporate decor for restaurants, hotels and hospitals, wherever an individual or organization is looking to ‘spice up’ a space with the unique look of canvas.

For sign and print shops, it is important to consider such factors as materials, printers, ink sets and coatings when determining the best way to produce canvas prints for the local market.

Materials and textures

The inkjet-printable canvas materials currently available vary by base material, weave, weight, finish and optical brightening agents (OBAs). Choosing the right canvas is a mostly subjective matter, since different customers like different appearances. Some may seek a highly textured surface, for example, while others prefer a smoother finish. The choice may also depend on the lighting where the canvas is to be displayed.

So, when discussing a canvas project with a client, it is important to understand his/her expectations, the project’s budget and where it will be displayed.

[2]

[2]Colortec Graphics and Design printed a 6.4 x 4.5-m (21 x 14-ft) canvas application to frame the main dining area at the Colosseum Italian Restaurant in Naples, Fla.

Polyester

A polyester base material is typically used for higher-volume projects because it is less expensive and smoother than other options. It is often used for decorative signage, banners, wallcoverings and other decor applications.

Some clients like the smoother surface for photography reproductions where a texture could detract from the image, while other artists would prefer a more traditional canvas texture appearance. While choosing esthetics will mostly be based on what a given client likes, however, the economics of production may be what dictates the choice of polyester.

Cotton

When most people envision an art canvas, they are thinking of the texture of 100 per cent cotton. That said, because cotton comprises 100 per cent natural fibres, there are more likely to be variations in the material’s whiteness, weave and texture from lot to lot, which can cause problems if a project requires consistency from print to print.

Some print shops find the variability of cotton is an advantage, however, as it provides a very original look for each of their products, allowing them to position themselves as custom, one-of-a-kind printers.

[3]

[3]The texture of canvas is determined by the diameter of the threads used to create it and how tightly they are woven.

Polyester/cotton blends

The most common base materials overall are polyester/cotton blends. These are designed to split the difference between the esthetic qualities of cotton and the production consistency of polyester.

Most of the blends use a polyester-to-cotton ratio of 60:40, emphasizing the importance of polyester’s consistency, which ensures the first print will look the same as the 50th.

Threads

In addition to the base material, the texture of canvas is determined by the diameter of the threads used to create it and how tightly they are woven. The tighter the weave, the less visible the texture in the finished print.

The ratio of threads on the loom running in the X and Y directions also affects the texture. A canvas with a two-over-one weave has more texture than a one-over-one weave, since there are more loops per square centimetre.

It is worth noting even a highly textured base canvas may lose some of its look if coatings are applied to change the finish or make it more resistant to water or ultraviolet (UV) rays. The more coatings are applied, the more they will fill in the peaks and valleys of the material to create a smoother finish.

Weight

Inkjet-printable canvases typically range in weight from 454 to 624 g (16 to 22 oz), though there are also lighter and heavier options. A heavier canvas is more durable during stretching, finishing and handling, while a lighter canvas will usually prove more economical.

Matte

A matte finish is usually preferred for fine art reproductions and for lighting situations where glare could be an issue. The downside of a matte finish is a smaller colour gamut. If there are a lot of bright colours in a graphic that require greater accuracy, then a satin or gloss finish may be better.

That said, adding a gloss coating to a matte canvas can help make images ‘pop’ despite their restrained colour gamut. And for most applications, the colour gamut of many matte canvases is more than adequate.

[4]

[4]A satin finish provides a sheen that is less susceptible to glare than a gloss finish. It also expands the colour gamut.

Satin

A satin finish provides a sheen that is not as susceptible as gloss to glare and expands the colour gamut. Typically, this finish is chosen simply because the client likes how it looks.

Gloss

A gloss finish is a great option for canvases designed for use in solvent-based or durable aqueous ‘latex’ inkjet printers, since it allows the coating step to be skipped, saving time and money.

With latex printers, it is important to be extra-careful when stretching the material, as a gloss inkjet coating is more likely to crack than other finishes are.

One option for artists who prefer a matte finish, but are diligent about hitting their colours as accurately as possible, is to print to a gloss canvas and then add a matte coating.

OBAs and archiving

OBAs have been used as additives in photographic papers since the 1950s, but photographers have a love-hate relationship with them. While they increase the whiteness of the material and the colour pop of the images, they may also reduce the archival qualities of the prints.

Fortunately, international archival specifications have been developed that allow for chemical additives to brighten and stabilize printable materials. Many of the popular fine-art papers and canvases alike use OBAS and have been tested for archival quality, often obtaining 100-plus year ratings.

[5]

[5]Canvas stretching machines can help automate the finishing department.

Wide-format printers

When choosing a printer for canvas, the volume to be produced is an important consideration, but so too are the sign shop’s capital equipment budget, market focus, current production and application mix, post-print finishing capabilities, desired clientele and those clients’ expectations (e.g. image fidelity vs. economical price).

The hardware choices for wide-format printing used to be fairly simple, but this simplicity also brought limitations. Over time, with the introduction of increasingly reliable and affordable UV-curing, solvent-based and latex printers, the number of potential applications that could be addressed grew and questions of print durability became less of an issue.

Each printing technology still has specific characteristics that need to be taken into account, of course, based on a sign shop’s goals, budget and operating environment. While there is no such thing as a single perfect printer, there are certainly ideal printers waiting to be used to their full potential.

Aqueous

In an aqueous inkjet printer, the ink is primarily water-based, mixed with either dyes or pigments. These devices are widely used for canvas printing and typically offer the best image quality, with pigments providing greater print durability than dyes. Indeed, pigmented inks have become the industry standard, as they eliminate much of lamination that was previously required for dye-based inks in short-term outdoor and long-term indoor applications.

While lamination may not be required, it is still recommended to coat an aqueous inkjet-

printed canvas to protect it against cracking along the edges when stretching the material, as well as against environmental factors. Liquid coatings also help enhance the texture of canvas, providing more of a ‘painted’ artistic look, and are available in gloss, satin and matte varieties.

Another advantage of an aqueous inkjet printer is versatility, as it can also provide excellent colour reproduction and graphic longevity on photo paper, polypropylene (PP), polycarbonates and fabric. (Some specialty applications, such as vehicle wraps, are more difficult and time-consuming.)

Further, these printers carry a significantly lower upfront cost than a solvent, latex or UV-curing printer—but the greatest expense, due to time and labour, is in finishing. From printing to shipping, sign shops can expect to add at least 48 hours to production, since they should wait 24 hours before coating and 24 hours before stretching. Even with automation in the finishing department, such as coating and canvas stretching machines, the lag time is an important consideration.

In a gallery wrap, the image bleeds onto and over the edges of the frame.

Fortunately, aqueous printers are virtually ‘plug-and-play,’ requiring very little time to tweak them for different materials. They also require little maintenance, other than keeping the production area as clean as possible. For these reasons, they are the most reliable printers over the long haul.

Aqueous printing is also arguably the environmentally friendliest wide-format technology. The inks are water-based and their cartridges are easier to recycle and reuse, which is also an economical benefit.

Unlike most solvent-based and UV-curing printers, aqueous inkjet printers do not need to be vented or filtered for a safe work place. Print shop employees will breathe easier.

In terms of quality, aqueous will provide a better print with a wider colour gamut at production speeds than other printing technologies, but the wider the gamut, the slower the speed. It is important to check what a printer’s speed will be in its highest-quality mode.

Aqueous printers tend to use thermal printheads that do not last as long as the piezoelectric printheads found in most solvent printers (and some aqueous photo printers). Fortunately, thermal printheads are less expensive to buy and replace.

[6]

[6]Choosing a canvas paper with an acid-free neutral white base is key for archival images.

Latex

While latex inks are also aqueous, they are more durable and scratch-resistant, such that a latex-printed canvas will generally not need to be coated. And for instances where a customer prefers the appearance of a coated print, lamination can occur right away, since the ink is instantly dry and outgassed.

The quality of latex prints has been inching closer to aqueous quality, but the difference is not a major issue anyway; most wide-format inkjet printers will produce the quality necessary for high-volume canvas decor production. Sign shops providing custom work for pickier clients should request samples from printer manufacturers or even distributors—using client-supplied files—before choosing which device to buy.

Latex ink and media costs are about the same as for other aqueous and solvent printers. No special ventilation is required to meet occupational exposure limits, there are no requirements for air discharge permitting and the printed graphics emit extremely low levels of volatile organic compounds (VOCs).

Latex printers require more maintenance than other aqueous printers, but less than a solvent or UV-curing printer.

Solvent

At a time when commercial signmakers continually complained about the outdoor durability of printed graphics, solvent printing was a godsend when it arrived on the scene. Manufacturers developed ink sets that could penetrate and permeate vinyl, whereas aqueous inks were anchored by coatings to sit on the surface of the material. If an aqueous print could be thought of as a sticker, solvent was more like a tattoo.

Most early solvent inks were caustic and could penetrate just about any material. Since then, the sign industry has moved toward lower-solvent and ‘eco-solvent’ inks, which require some level of substrate pre-treatment or coating to ensure strong adhesion.

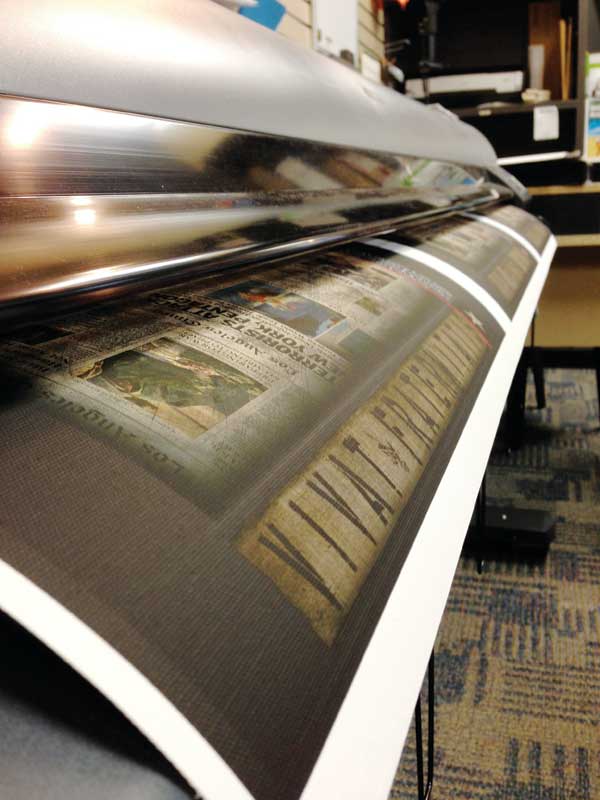

[7]

[7]These graphics were printed onto matte canvas, wrapped on stretcher bars and finished with a satin coating.

Today, even fine-art reproduction companies have migrated to solvent printing, as it eliminates the need for post-print coatings. They can simply choose a canvas finish—i.e. gloss, satin or matte—and move straight on from printing to stretching.

There is a vast range of solvent printers available today, including some low-solvent models with prices, image quality levels and capabilities that are similar to aqueous inkjet printers in the canvas market. A solvent printer will typically cost more upfront, but carry lower ink and media expenses.

Outside of minor maintenance, typically an hour or less per month, today’s solvent printers can be run continuously. While they can produce durable graphics on canvas and other materials that do not require lamination or coatings, there is usually a recommended period for post-print drying and outgassing.

As mentioned, most solvent printers use piezoelectric printheads, which are more durable than the thermal printheads typical in aqueous printers.

UV-curing

UV-curing printing is the only wide-format technology that allows graphics to be printed directly to rigid materials, such as corrugated plastic, polystyrene (PS) display boards, polyvinyl chloride (PVC) foam boards and even doors and tabletops. The inks are cured using built-in UV lamps, so they can adhere to a wide variety of materials. Their durability rivals solvent inks and they rarely need any lamination, unless a different texture is desired or, for roll materials, additional rigidity.

The printing process usually requires an air filter, but the emissions are not nearly as voluminous or harmful as those from solvents. And in terms of environmental impact, the ability to print directly to rigid materials—rather than on vinyl that is later mounted to a rigid backing—helps eliminate material waste.

Today’s ‘hybrid’ UV-curing printers can switch from flatbed printing of rigid substrates to roll-to-roll (RTR) printing on flexible materials, but their inks are generally not designed for canvas printing. Specifically, they are not flexible enough for the stretching process (though they may be fine for mounted, pre-stretched or framed canvas prints). Indeed, almost all applications are ‘fair game’ for UV-curable inks, but the most notable exceptions are vehicle graphics and stretched canvas, both for reasons of flexibility.

With that in mind, UV-curing printers should only be considered a last resort for canvas printing. Some signmakers use them to print directly onto a pre-stretched blank canvas, but then they will usually have to paint the edges, as most clients expect either a ‘gallery wrap’ (where the image continues onto the edges of the frame, usually mirrored) or a ‘museum wrap’ (a solid colour on the edges).

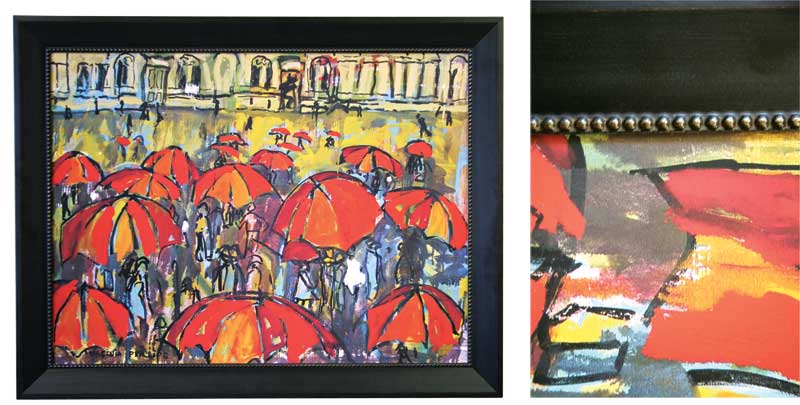

[8]

[8]Some shops specialize in fine art reproductions on canvas substrates.

Coatings

As previously noted, it is highly recommended for all aqueous inkjet-printed canvas output to be coated. This will help ensure crack-free, consistent stretching, particularly for ‘gallery wrap’ applications. There are exceptions, such as short-term applications (including temporary decorative pieces). And when using a solvent or latex printer, coating is not necessary unless the client specifically wants to achieve the appearance of coated canvas.

Coatings are typically available in either gloss or satin (lustre) finishes. Gloss coatings are often chosen to provide additional protection for the canvas or to bring out the density of the blacks and the vibrancy of the colours in the graphic, while satin or lustre coatings may be preferable for a more subdued appearance or to reduce glare from high levels of lighting.

There are both spray and liquid coatings available. It is important to choose products that have been specially formulated for and tested with inkjet-printed fine art and photography. The long-term effects of other ‘off-the-shelf’ coatings on canvas graphics are unknown.

Liquid coatings can be applied by automated machines, which are available in a variety of widths and are designed to operate in a controlled environment, with consistent temperature and humidity and free of dust and dirt. Other liquid coatings come in cans; these may be brushed or rolled onto the canvas or applied with a high-volume, low-pressure (HVLP) spray gun, which also requires a well-ventilated and dust-free environment.

Compared to other sprayers, an HVLP spray gun provides more control over the application process and wastes less of the liquid coating in overspray. Some sign shops do not have sufficient space for spraying, so they opt for coatings that have been formulated to work equally well when applied by brush or foam roller. (That said, it may be possible to set up a spray booth in a limited space.)

When rolling liquid coatings onto canvas, these steps should be followed:

- Make sure the ink is dry. A good rule of thumb is to wait 24 hours, but to test whether or not a print is ready for coating, lay the canvas on a flat surface and cover it with butcher paper. The evaporating glycols will cause ripples to appear in the butcher paper, which should be replaced periodically when it is wavy. If no waves appear in a fresh sheet after a few hours, then the print is dry enough to coat.

- Start with a high-density white foam roller and a tray typically used for holding paints; both are available in the paint department of any home improvement store. The high-density foam will help reduce bubbles. A larger roller should be used for coating a larger canvas.

- Pour the coating into the tray and dip the roller in until it is thoroughly wet, but not too wet.

- Lay the graphic down on a clean, dust-free board that is bigger than the print. The extra space on the surface around the print can be used to roll off excess liquid if the roller becomes oversaturated.

- Apply two or three thinner coats, instead of one thicker coat.

- Don’t try to coat the whole print at once. Start with one or two passes at the edge. Go over each pass enough times for the bubbles to dissipate, but not so many times that the coating becomes tacky or bumpy.

- If large bubbles appear, try blowing onto the coating.

- Make overlapping passes to maintain a wet edge and avoid lines and streaks.

- Find a rolling pattern that works well. Some users prefer to go up the print in the first pass and down in the second, like mowing a lawn.

- Don’t press down on the roller. Maintain light, even pressure.

- Allow the first coat to dry before applying the second. A thin coat should take between 10 and 30 minutes to dry, but longer in a high-humidity environment.

- Allow the final coat to dry before packing the print for shipping. Don’t try to speed up the drying process with a fan; just allow the print to dry on its own.

- Clean the rollers immediately after each use, running cool water over them and then squeezing them until they run clear. Allow 10 to 15 minutes. Rollers that are kept clean can be used for about six months before needing to replace them.

- Wait at least six hours after applying the coating before stretching the canvas.

Generally speaking, coatings formulated for wide-format printing will work well with both aqueous and solvent prints. As more types of inks and canvas-based substrates are introduced, however, it is virtually impossible to predict the compatibility of every combination of media, ink and clearcoat. This is why testing is strongly recommended before actual use.

A test will immediately show if there are any incompatibilities, including water sensitivity, inkjet-receptive layer ‘mud cracks’ and ink bleeds. The tested material should be allowed to dry for at least 24 hours before evaluating the adhesion, flexibility and visual appearance. It should also be tested under simulated conditions similar to those to which the material will be exposed in real-world applications, so any expectations will be realistic.

Stretching and wrapping

Well before the canvas is physically stretched and wrapped, it is important to prepare the graphic files for printing, so they can be suitable rendered as a gallery or museum wrap. As mentioned earlier, in a gallery wrap, the image bleeds onto and over the edges of the frame; and in a museum wrap, a solid border is substituted along the edges.

A gallery wrap’s bleed usually mirrors the image along the border. This can be set up manually in graphic design software using a ‘clone’ tool. Some types of software offer solid border, reflected edges and/or fade effects. In other cases, a ‘resize’ tool allows users to create selective, mirror, museum wrap and other types of borders. And some inkjet printers even feature layout plug-in software that can automate the process.

There are typically three ways to stretch a canvas print: (a) by hand, with stretcher bars and strainers; (b) using a canvas stretching machine, with some degree of automation; and (c) using a do-it-yourself (DIY) stretcher bar system.

Stretching canvas by hand can be very involved and time-consuming, but the raw materials needed for the process are less expensive. Stretcher bars and canvas frames can be built in-house.

Canvas stretching machines, on other hand, cost thousands of dollars, but are much more efficient. If a sign shop’s volume of canvas prints supports the business case, then these machines should definitely be investigated.

“We use a canvas stretching machine for just about everything up to 1.5 m (60 in.),” says Armando Garcia, director of operations for Soicher Marin, a high-volume fine-art reproduction company. “When you compare it to doing it by hand, the machine always wins out. I can’t think of a situation where we wouldn’t use the machine, unless it was an original canvas.”

Garcia explains it usually takes about one-and-a-half days for an operator to learn how to use the machine to its full potential, cutting the time needed for a canvas wrap by anywhere from 30 to 50 per cent.

The third option is to use a pre-made DIY stretcher bar kit. This is a happy medium between stretching by hand and automating the process—faster than the former, less expensive than the latter. There are easy-to-assemble tongue-and-groove stretcher bars available, so signmakers do not have to buy raw materials and cut them down to size.

Jeff Goetze is a national account executive for LexJet, which manufactures and distributes materials and equipment for wide-format inkjet printing. For more information, visit www.lexjet.com[9].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/canvas_Sunset-Reserve-Matte-Canvas-Print.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/canvas_Dining-Room_01-REV_03.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/canvas_IMG_2763.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/canvas_New-Era-Portfolio-on-Sunset-by-Fredrix.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/Canvas-Stretch-Master.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/canvas_Sunset-Photo-Canvas-Paper-230g-Copy.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/canvas_Printing-UNTIL-It-HURTS-at-PostNet.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/canvas_Bill-Barley-Fine-Art-Finishing-IDAC.jpg

- www.lexjet.com: http://www.lexjet.com

Source URL: https://www.signmedia.ca/wide-format-graphics-canvas-printing-for-sign-shops/