Wide-format Graphics: Choosing the right adhesive films

While a graphic printed on a typical white vinyl film may initially appear to stick well to a certain plastic surface, over time it could become apparent the film’s adhesive simply wasn’t designed for such an application. It might not stand up to normal use and the application could fail.

Such failures are caused by the plastic itself—specifically, by plasticizers inside it that help it look fresh and maintain its colour. These plasticizers can migrate out of the surface, creating an oily surface that in turn causes the graphic to fail.

A film with an LSE adhesive is specially formulated to bond to these difficult, non-standard surfaces, so choosing the right product will allow the signmaker to stand behind the project with confidence.

The second specialty category is for adhesives that can be applied successfully to stainless steel. For interior application surfaces, such as elevator doors, it is not typically necessary to stray from typical product lines; an ultra-removable adhesive is usually the right choice, as the graphics are most likely for short-term promotional purposes. With exterior applications, on the other hand, projects installed on stainless steel—e.g. tanker truck graphics—can easily fail unless they use specialty films and adhesives.

A tanker truck, after all, is exposed to salt spray and moisture on highways, which react with its stainless steel cause the graphics to fail. A specialty adhesive for this purpose, however, will withstand the elements yet also be removable when desired, with heat and/or chemicals.

Cast vs. calendered

Cast films are designed for long-term projects, whereas calendered films should only be used for shorter-term graphic applications.

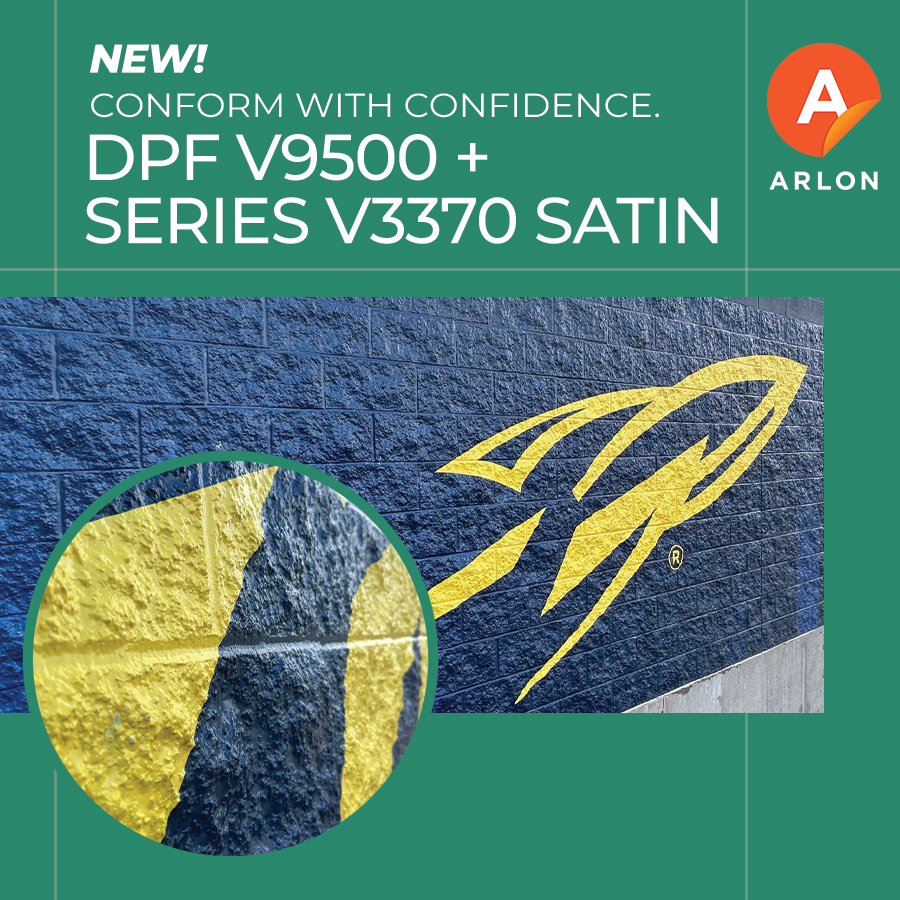

Films that look alike may have very different properties. It is important not to send a less expensive calendered film to do a more expensive cast film’s job. Even if a calendered film has the right adhesive in place, if it is applied to a surface with deep grooves, it will fail.

In addition to polyvinyl chloride (PVC) cast films, recent advances have led to the development of highly flexible and conformable reflective films, as well as non-PVC cast films, to meet a wide array of client objectives. They work well on vehicle wraps and highly textured surfaces, preventing the types of failures that can cost sign shops extra money or, even worse, their reputation in the marketplace.

Enhancing protection and appearance

Moving beyond the customer’s objectives in terms of appearance and duration of use, it is also important to discuss how to protect the graphics from dirt, fading and vandalism with an overlaminate.

Determining the best method for protecting graphics will depend on location and desired appearance. Many clients will want a matte finish for their indoor graphics, for instance, where a gloss finish would reflect too much light and make it hard to see the images. For printed vehicle wraps, on the other hand, gloss is the most-requested finish. And with graphics that are to be applied to outdoor surfaces prone to vandalism, a graffiti-resistant overlaminate is the best choice.

In addition to standard overlaminate options like gloss, lustre and matte, there are also ‘ultra-matte’ and textured options like linen and wood grain, along with sparkle effects. So, in addition to protecting graphics, there are growing numbers of ways to help clients achieve the specific look they want.