Beyond necessities

Beyond necessities

In addition to avoiding bottlenecks in the finishing department, another primary reason to invest in a digital cutting system is to expand a PSP’s capabilities in terms of the shapes and dimensions that can be achieved, with a greater number of substrates. In these ways—and by considering the size of a PSP’s digitally printed output before selecting a table—digital finishing can help achieve a better ROI for a shop’s existing digital printer.

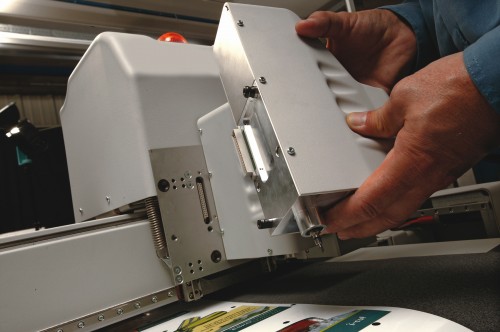

An automated finishing table can cut, rout and crease or score the substrate. Beyond these basic functions, however, it should be versatile, able to properly handle a wide range of materials—from delicate sheets to highly durable plastics, woods and metals—and offering a broad selection of finishing capabilities.

In today’s competitive market, many professionals consider speed the most important feature of a machine, but they do not always consider how efficiency depends on acceleration. It takes some time for a cutting table to ramp up to its maximum speed, but any job that requires small or contoured cuts, not just long ‘straightaways,’ will challenge a table that cannot accelerate quickly enough to its rated speed. The problem is similar to driving a massive truck around hairpin turns.

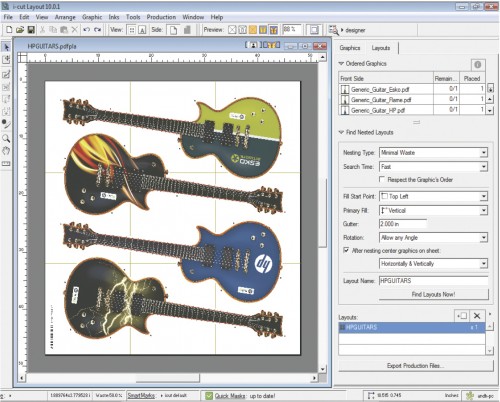

Productivity also depends on integration with the workflow, from design to printing to cutting. If the table is not a good fit for this workflow, it will be difficult or impossible to complete jobs on time.

In this regard, vision registration systems have become more prevalent. It is impossible to be completely sure a sheet of material will be manually placed on the table correctly, so the vision registration system is used to correct the die line for distortion. Otherwise, with contoured cuts, blank spaces could end up being left on the printed piece as it is finished.

Beyond ensuring a printed substrate is ‘read’ correctly, a vision recognition system can also read registration marks around every piece when materials have been ‘ganged’ together with more than one printed graphic. This ensures the cutter can compensate for pieces with distortion.

Finally, there is the issue of automation. To maximize productivity, some of today’s cutting tables can handle rolls, sheets and boards without needing an operator to manually load and unload the materials. Indeed, many cutting tables come with conveyor belts, roll feeders, sheet and board feeders and/or table extensions.

Added dimensions

Finding an appropriate cutting table is just the beginning of the process. Typical printed signs are becoming a commoditized business, with PSPs of all kinds producing them on digital presses, cutting them into rectangular shapes and shipping them around the world. Just about anyone can do that.

Without value-added features, such as colour management, these companies will compete simply on the basis of pricing and availability. If they all continue to handle the same jobs in the same way, they will end up walking into a business trap.

Similarly, while buying an automated digital cutting table can help a sign shop optimize its availability and costs by adding volume through capacity and productivity, the machine itself is not going to differentiate that shop from everyone else.

Rather, signmakers need to approach existing customers and offer greater capabilities. When clients order two-dimensional (2-D) graphics, for example, they should also be offered contoured shapes, cutting, creasing and a greater range of substrate options. These types of work will also be more creatively fulfilling to the sign shop’s in-house designers.

One way to foster this creativity and value-added business is to invite customers into the shop, as early in the process as possible, and show them a range of specially created samples, to exemplify what the in-house production department is capable of handling. The key is to work with customers and guide them up the value chain, exposing them to a range of materials and applications of which they may not even have been aware.

Customers who are accustomed to flat graphics should be offered three-dimensional (3-D) point-of-purchase (POP) graphics, stand-up displays and boxes for trade shows, meetings, special events and showrooms.

This will get clients’ creative juices flowing and will free them from the constraints of ‘rectangular thinking.’ Greater creativity, in turn, will lead to higher margins. Displays can be priced by the piece, rather than by the square foot.

In regard to working with customers, most structural design software suites include templates to help them visualize 3-D displays, which the PSP can help the client custom-design for finishing. Indeed, some sign shops now provide structural computer-aided design (CAD) services themselves, working with graphic designers, which helps make them more indispensable to their customers.