Wide-format Graphics: How 3-D printing is shaping up

by all | 14 February 2017 10:15 am

[1]

[1]Photos courtesy Massivit 3D

By Lilach Sapir

With three-dimensional (3-D) printing processes, a new object is created synthetically through additive manufacturing. To accomplish this, a series of layers of a binding material are deposited via inkjet printheads, as per the instructions contained in a computer file, allowing nearly any shape or size of product to be produced.

It is certainly understandable if 3-D printing seems like a relatively new phenomenon, given the many attention-grabbing headlines that have recently showcased how the technology is changing the world of manufacturing for the aerospace, automotive and medical industries, among others, but it has actually been around for more than 30 years. Over that time, it has evolved from short-run prototyping to play an increasingly important role in a wider variety of production processes, to the point where it now has viable implications for the sign and large-

format graphics industry.

Indeed, some sign companies have already become early adopters of 3-D printing, after recognizing its potential to enhance their business. For them, the technology is an enabler, unlocking the door to new projects, whereby vibrant, eye-catching displays can go beyond the visual impact achieved with two-dimensional (2-D) large-format printing.

[2]

[2]Fashion retailer Louis Vuitton recently commissioned what may be the world’s first 3-D printed pop-up store.

The wow factor

More than ever, today’s brand marketing managers are seeking to maximize the ‘wow’ factor of their signage and graphics. Retailers, too, are looking to transform their environments to better engage and entertain their customers. Research shows 3-D printed ads have five times more ‘stopping power’ and four times more ‘staying power’ than 2-D posters, making them a great tool for exhibitry, point-of-purchase (POP) displays, billboards, bus wraps and other attention-grabbing graphics.

The ‘traditional’ large-format digital printing industry is still growing, but can nevertheless be a difficult arena in which to compete, particularly as customers continue to demand faster speeds, improved quality of output and an ever-expanding range of substrates. And to some extent, the level of opportunity in this sector has already reached its peak, with regard to print speeds, output quality, the range of achievable projects and the profits they can generate.

To help increase their profitability further, some signs shops are expanding their processes to embrace 3-D printing with systems that now offer the flexibility, speed and price point necessary to support new, creative opportunities and add value for their customers.

To date, educating the market has been the main barrier to the uptake of this technology. For most of the aforementioned 30-plus years of 3-D printing, there has been a lack of mainstream awareness of the technology and how it works.

In recent years, more people have acknowledged and appreciated the wide-ranging benefits offered by 3-D printing, but it has not yet been broadly used for the production of signs and graphics. As with any new technology, further education and strong support will be fundamental to broader adoption. Ensuring 3-D printing technology is readily available to print service providers (PSPs), they are aware of it and they can quickly and easily integrate it into workflow will all be key to its success.

[3]

[3]Colourful 3-D elements printed for The Angry Birds Movie‘s bus wraps inspired a similar promotion for Ghostbusters.

Real-world examples

That said, some sign shops around the world have used 3-D printing for spectacular applications. Carisma, for example, is a commercial printing company in New York, N.Y., that used a gel-dispensing 3-D printer to produce enhanced elements for double-decker bus wraps promoting two of Sony Pictures’ high-profile 2016 releases, The Angry Birds Movie and Ghostbusters (see Sign Media Canada, November 2016, page 18[4]).

“Initially, we produced one Angry Birds model to demonstrate our capabilities,” Carisma CEO Moshe Gil explains. “Sony was immediately taken with the quality and scale and increased its order in the run-up to the movie’s release. Then, they were so blown away by the attention generated around the campaign, they sought something similar for Ghostbusters.”

Carisma’s 3-D printer is capable of producing pieces up to 1.8 m (6 ft) tall. To promote Ghostbusters, the company produced a series of components that were assembled into 10 ‘no ghost’ signs, recreating the movie’s famous logo at a height of 4.3 m (14 ft), which were then affixed to a fleet of buses and illuminated.

“Bus wraps are not new for companies like ours, but the ability to offer 3-D printed versions takes the application to new frontiers,” says Gil. “Before this printer, there was a substantial gap in the market for producing large-scale models with a super-fast turnaround time.”

[5]

[5]Nearly any size of product can be produced.

Having gotten the word out in a highly visible fashion across the U.S., Gil adds he is starting to think about purchasing a second 3-D printer to meet future demand.

In another example, ES Digital, a wide-format print shop in Yavne, Israel, used 3-D printing to produce a ‘selfie point’ for a cross-media campaign that was displayed throughout the country’s international Ben Gurion Airport near Tel Aviv. Another Israeli company, the Heidia Group, has recently invested in the technology in anticipation of a new competitive edge in the retail brand development market.

“We are continually looking at how to stand out from the crowd and we believe this investment will support that objective,” says Ofer Gal, Heidia’s chair. “It will allow us to elevate our traditional 2-D POP displays to new levels and unlock new business opportunities.”

Stylo Graphics, which prints wide-format displays in Watford, England, has used the technology to produce a broad range of dimensional models for the retail, interior design and hospitality sectors.

“Our clients are blown away by the ability to produce personalized, larger-than-life 3-D models,” says Simon Olley, Stylo’s owner. “As an early adopter of the technology, we can propel our business into exciting new markets.”

[6]

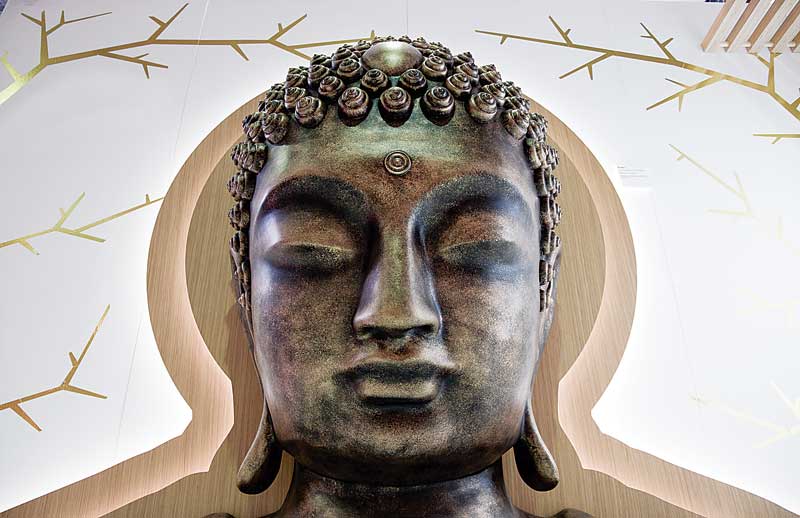

[6]This 3-D printed model of Buddha was vacuum-formed with fibreglass to ensure it would withstand the elements.

Similarly, in the suburbs of Melbourne, Australia, On-Demand Manufactured Unique Solutions (OMUS) has printed a variety of 3-D pieces for retail, staging, display, event and architectural applications.

“Our experience coupled with the printer’s capabilities will change the display landscape,” says Robert Grosso, co-owner of OMUS, “and we’ve only just scratched the surface in terms of the possibilities that are achievable.”

By way of example, OMUS recently built what may be the world’s first 3-D printed pop-up retail store, on behalf of luxury fashion retailer Louis Vuitton, for the Westfield Sydney shopping centre in Sydney, Australia. There was only a three-week period between client confirmation and the grand opening.

“Having received the design brief, we needed to produce—in record time—a visually stunning, structurally sound outlet that could endure sustained use in a busy public environment,” Grosso says. “Given the complexity of the design and the short turnaround time, 3-D printing was really the only viable production method available to us.”

To assist with the magnitude of the 9 x 10 x 2.7-m (29.5 x 32.8 x 8.85-ft) structure, OMUS worked with Sydney-based Composite Images. Between them, they ran two 3-D printers around the clock to create 30 panels, which served as the pop-up store’s walls. After adding solid support ‘ribs,’ the entire display was finished in self-adhesive ‘chrome mirror’ vinyl and adorned with animal prints matching the theme of the menswear collection on display.

Factors for success

While 3-D printing technology has evolved steadily over the past three decades to serve an increasing number of markets, revolutionizing the way many products are made, its nascent acceptance by the sign and graphics industry can be largely attributed to (a) much greater print speeds than were possible in the past and (b) the development of suitable materials.

Thanks to these factors, sign and graphics companies can feasibly produce high-quality, hollow, dimensional pieces and add them to their traditional 2-D graphic applications (much as Carisma has done with its bus wraps). Without the need to produce fully solid objects or special support structures, turnaround times are inherently shorter. Further, a single 3-D printer can produce two large objects at the same time.

With less work needed to achieve the same results as other dimensional signmaking techniques, shops that adopt 3-D printing are enjoying increases in productivity and manufacturing efficiency, while reducing material costs and, for that matter, the weight of their output, which is pivotal to the ease and costs of handling, transportation and storage.

It is also worth noting the automation that comes with 3-D printing eliminates the inconsistency typically associated with hand-crafted signs, yielding stronger repeatability for recreating clients’ brand standards. This can be important in not only maintaining the loyalty of existing customers, but also winning over new ones.

As for the materials, by 3-D printing with a white base, many finishing options become available, from vacuum-forming pieces for outdoor use to wrapping them with specialty vinyls. The aforementioned Stylo Graphics, for example, vacuum-formed a 3-D printed model of Buddha with fibreglass to ensure it would withstand the elements.

Another opportunity is in digital signage. By integrating screens into 3-D printed housings, sign shops can better catch the attention of passersby.

A new dimension

In these ways, 3-D printing is enabling print service providers (PSPs) to extend their existing portfolios of offerings by combining traditional signs and displays with new, creative innovations. And since the technology has only just reached the graphic arts sector, the time is ripe for more sign shops to seize the day and establish an early lead in their markets as pioneers with new service capabilities. They can literally add a new dimension to their business.

Lilach Sapir is vice-president (VP) of marketing and business development for Massivit 3D Printing Technologies, which manufactures 3-D printers in Lod, Israel. She previously worked in the wide-format printing industry. For more information, visit www.massivit3d.com[7].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/3D_Carisma-Ghostbusters-e1486656467538.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/3D_OMUS-1.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/3D_AngryBirds_main.jpg

- Sign Media Canada, November 2016, page 18: http://www.kenilworth.com/publications/smc/de/201611/18.html

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/3D_Massivit1800-with-Print-plus-Screen.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/02/3D_Picture-courtesy-of-Stylo-Graphics.jpg

- www.massivit3d.com: http://www.massivit3d.com

Source URL: https://www.signmedia.ca/wide-format-graphics-how-3-d-printing-is-shaping-up/