Founded in 1954 as a screenprinting company, Eclipse Imaging of Burlington, Ont., now offers a mix of lithography and digital large-format printing.

The one-stop kitting shop

The latest advances in digital printing technologies have led to dramatic shifts for many PSPS, allowing them to expand their capabilities, vary their run lengths and shorten their turnarounds. In turn, their customers’ expectations have changed.

As mentioned, while traditional lithographic printing is not going away anytime soon, shops like Eclipse have invested in digital printing technologies that represent new revenue streams and can thus foster future growth. In many cases, these revenue streams reflect a growing demand from the retail sector for flexible displays and ‘kitting.’

Online publication Retail Dive recently compiled a list of 10 major trends shaping the future of the retail sector. Among these was recognizing the growing importance of ‘face time’ for retailers and their brands through in-store experiences for customers. With this in mind, brand marketers are investing more heavily in merchandising displays.

Therein lies the opportunity for PSPs. With the growing demand for improved in-store presence, both brand marketers and retailers are looking to PSPs to do more than just traditional print jobs. In particular, they expect them to go beyond printing and manufacturing their displays, signage and marketing collateral by also packaging and distributing promotional kits to their various store locations.

Kitting is a common practice among retailers that involves grouping together related merchandising materials, including product samples, promotional literature, instructional packets and marketing pieces. As PSPs are already responsible for producing many of the included materials, it is no surprise retailers and brand marketers are also turning to them to package the kits.

Also, since today’s PSPs can handle larger volumes than before, in less time, they offer a more cost-effective method for kitting than if retailers or brand marketers handled the task in-house. The more kits that can be produced at one time, the lower the assembly time needed for each and, in turn, the lower the cost per unit.

To be fair, capitalizing on this trend is not merely an issue of investing in technology.

In Eclipse’s case, for example, buying new printers helped the PSP provide new kitting services, but only because the company also invested in new manpower and know-how for managing multiple creative endeavours, as well as additional physical space for storing the materials that go into the kits.

Keeping pace

With the proliferation of digital printing technology, the phrase “time is money” has never been more relevant to PSPs than it is today, as they face tighter deadlines and greater competition and must focus on speed to market. Both UV-curing and latex printers have helped them in these respects.

Further, advances in the speed, quality and versatility of digital printers have allowed PSPs to become more ‘agile’ and able to respond in a timely fashion to their customers’ changing priorities.

“To succeed in today’s printing industry, companies need to find ways to lower their overhead costs while improving efficiencies,” says Eclipse’s Misale. “Investing in new technologies is a relatively easy way for companies to find those gains.”

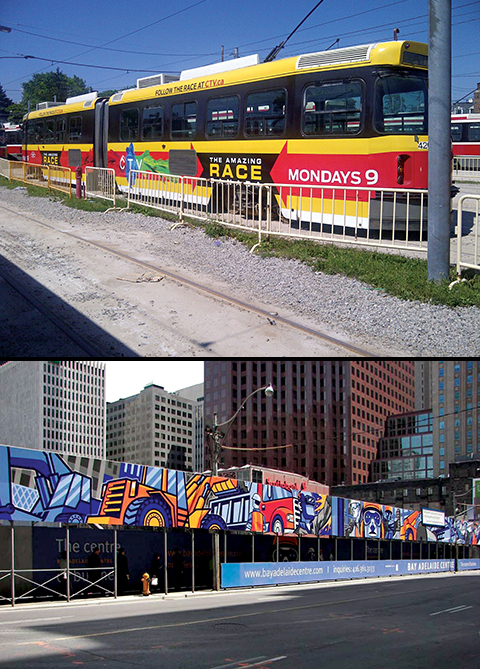

Eclipse’s investments in digital inkjet printing have yielded such applications as Toronto Transit Commission (TTC) streetcar wraps and long-term construction hoardings.

Closing the gap

In recent years, many traditional PSPs have moved what was previous offset work to digital equipment. This is largely due to improvements in the quality of digital presses and their inks.

High-speed digital flatbed printing, for example, has seen tremendous growth in the past two years with respect to the marketplace for corrugated output, thanks to the improvement of vacuum management technology on flatbeds to enable better control of warp and distortion with corrugated substrates.

While such capabilities have improved rapidly in recent years, there are still limitations to digital printing technology. For very large jobs—e.g. more than 10,000 units—traditional analogue printing methods like lithography and flexography still tend to be the most cost-effective options.

Closing that gap—as has already been accomplished to a large degree in the sign industry—remains both a priority and a challenge for press manufacturers and PSPs alike, but not an unsolvable problem. With new technologies hitting the market, the gap is already narrowing.

High-dynamic-range (HDR) technology, for example, avoids sacrificing quality for speed

by using precision control with true grayscale printing, achieving a clarity of image detail that rivals lithography, but at speeds not previously reachable at comparable quality levels.

So, moving forward, PSPs will face fewer dilemmas of trading quality for productivity, as they invest in new technologies, diversify their portfolios of services and improve the efficiency of their operations.

As the pace of business continues to quicken and competition increases further, success will only become all the more dependent on delivering distinctive value to customers. For forward-thinking PSPs like Eclipse, this has meant carefully investing in the right technologies today, to become ready for the challenges of tomorrow.

Kevin Sykes is country general manager (GM) of sign, display, Indigo and PageWide web press solutions for HP Canada. For more information, visit www.hp.ca.