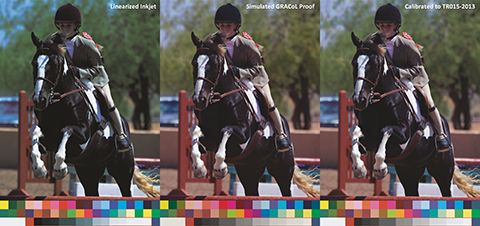

In this example used previously by Mutoh America’s Christopher Brown (see Sign Media Canada, September 2014, p.92), a linearized inkjet print (left) carries a green cast compared to a GRACoL proof (centre), which can be removed in another print by calibrating to a G7 standard (right).

Mastering the methodology

A G7 ‘master printer’ is a company, not a person, and the title does not represent certification, but rather ‘qualification.’ This involves a G7 expert—who has been trained and certified by IDEAlliance—visiting the company and documenting how it understands and performs G7 calibration of its equipment, including adjustments for substrate and colourant differences.

Some sign shops resist becoming qualified because they do not receive any requests from their customers for G7. This is missing the point, however. G7 improves productivity and accuracy in print production so as to increase profits on existing product sales. The customer need not know it exists.

Nevertheless, G7 can also offer a sales advantage. Some clients know about it and are starting to ask their print service providers (PSPs) if they are G7-qualified.

Even beyond these clients, G7 can be a powerful ‘closer’ in sales calls when sign shops are trying to acquire accounts for clients who are very demanding of accurate printing results, such as major fashion and food retailers. Explaining the G7 advantage can mean the difference between landing these accounts or seeing them go to a non-G7 competitor.

With this in mind, G7 master training and qualification can be followed by G7 sales training. This will help sign shops’ managers and other key personnel better understand how to inform clients about their use of G7 during sales calls.

It is common, after all, for demanding clients to ask, “What makes you different from the other shops?” And if the only answers are quality, service and pricing, the customer may sense an echo of other competitors’ promises. If on the other hand the answer is, “We’re a G7 master printer,” and the client asks what that means, then there is a major opportunity to stand out from the pack.

Here is how that conversation will typically go:

Salesperson: “ If you submitted your graphic file to three other vendors, would their resulting prints match?

Print buyer: “No.”

Salesperson: “ So, if they are different, but all of them look pretty good, which one is accurate to your file?”

Print buyer: “There’s no way to tell.”

Salesperson: “ Actually, there is. Our company is a G7 master printer, which means we print to neutral, without adding a colour cast to your file. Our equipment and workflow are neutral. Using the G7 methodology, the prints we produce will be the most accurate reproduction possible of your file. This is why you should buy from us.”

If the salesperson can then show two samples of the same image, one grey-balanced and one not, along with a G7 colour bar on each print, then the client will see and understand the difference. And this is not only important with new prospects; existing clients will also care very much about accuracy.