Wide-format Graphics: The industrial printing revolution

by all | 2 September 2016 10:00 am

By Frazer Chesterman

By Frazer Chesterman

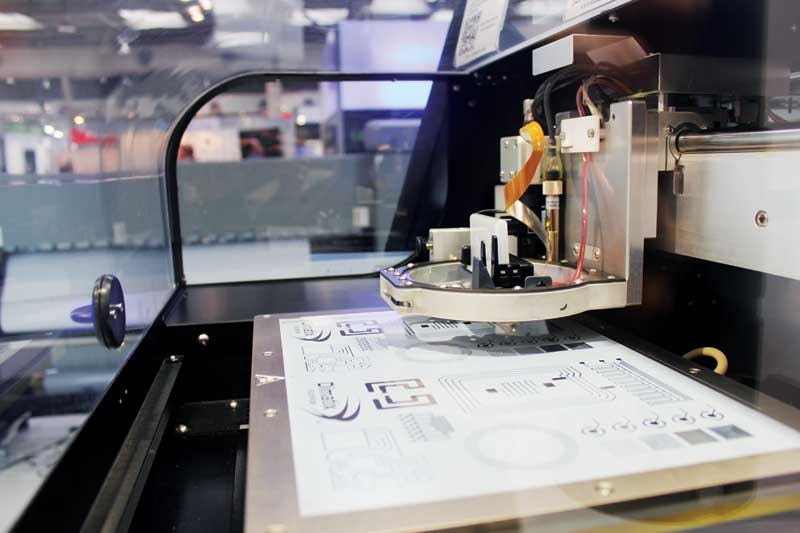

There is an ‘industrial revolution’ going on today in the digital inkjet printing industry, with rapid growth in new market segments for the depositing of inks onto manufactured products for decorative purposes. Examples that represent opportunities for sign shops include interior décor, ceramics, laminates and textiles.

Digital inkjet technology is opening these new markets today much as it did earlier for traditional commercial wide-format graphics, which now represent a mature market where growth is slowing down. The biggest or strongest wide-format printing companies are not necessarily the ones that will survive upcoming changes; rather, those that can evolve and adapt will be the most successful.

The changing landscape

The global market for functional and industrial printing was valued at $67.4 billion U.S. in 2015, up substantially from $31 billion U.S. in 2010, according to Smithers Pira, a market research and testing firm for the printing, packaging and paper industries. It is set to grow to $107 billion U.S. by 2020.

In January 2016, many printing industry professionals across the globe were surveyed for an Industrial Print Show (InPrint) market report, conducted with the assistance of IT Strategies, a consultancy serving digital print vendors. More than 50 per cent predicted a steady year-over-year growth rate of between five and 10 per cent for industrial printing, while nearly 34 per cent predicted double-digit growth (i.e. greater than 10 per cent). Only

15 per cent predicted zero to slight growth.

Western Europe has led the integration of industrial inkjet printing technologies and processes. Results of the InPrint survey suggest the next most significant manufacturing centre is North America (58 per cent), followed by China (43 per cent), Japan (36 per cent), Eastern Europe (27 per cent) and Southeast Asia (19 per cent).

Digital inkjet textile printers are creating not only soft signage, but also apparel.

On a global scale, the market for industrial printing is driven by changes in both supply and demand, as customers seek greater speed, efficiency and flexibility, while the shift to digital manufacturing makes local production more feasible for many applications.

Innovations in both digital printer technology and the related inks and coatings have driven the supply side of the equation. There have been improvements in ink deposition, adhesion and robust durability. Most importantly, digital printing has become a cost-effective method of manufacturing.

In the InPrint survey, nearly 70 per cent of respondents cited technological innovation as one of the main drivers of growth, followed by changing customer demand trends at 56 per cent, shifts to digital manufacturing at 42 per cent and localization at nearly 13 per cent.

Survey participants were also asked which benefits they were looking to gain when investing in new technology. The top answer, at approximately 75 per cent, was to open new application possibilities. This was followed by more flexible production (51 per cent), lower production costs (46 per cent), more customized production output (38 per cent), better-quality image reproduction (33 per cent) and more automated production output (29 per cent).

Across North America, it has become increasingly common for small craft breweries to inkjet-print their beer cans.

New applications

The fastest-growing applications include textiles, décor and laminates, while the digital printing of ceramics is already quite mature. The InPrint survey asked respondents which industry segments were enjoying the most significant growth. The top answer was packaging at 60 per cent, followed by textiles—including dye sublimation and direct-to-substrate printing—at 53 per cent and non-textile-based interior décor—including wooden, plastic, metal and glass surfaces, along with wallpaper—at 48 per cent.

Printing ‘direct-to-shape’ is taking off with packaging applications. In Israel, for example, a Coca-Cola campaign saw two million bottles printed with unique colours, designs and numbers. The inkjet printing process used special software and algorithms and allowed customers’ unique artwork to also appear on other items, including T-shirts and hats. In North America, meanwhile, it has become increasingly common for small craft breweries to inkjet-print their beer cans.

As mentioned, textile-based décor and fashion represent the second-largest potential market. Digital inkjet textile printers are being used to create not only soft signage, but also apparel, upholstery and soft interior décor. There is a plethora of new, energy-efficient machines designed to reduce setup time and support short print runs, which in turn is helping reduce obsolescence in printing companies’ inventories and making it more feasible to test and market new designs. Ink matching remains a challenge, but designs are not limited in their colour range.

Three-dimensional (3-D) printing has received plenty of hype, but also inflated expectations. It is not truly an industrial printing process. Modelling is still very difficult and even industrial-scale 3-D printers are too expensive, slow, small and inefficient for mass production. A lot of time is required to create complex shapes by printing layer upon layer. The repeatability of 3-D printed parts is quite low. The process is only valuable for highly customized and personalized applications with complex geometry, such as those in the dentistry business.

That said, texture is becoming more important in printed visual environments. Research predicts ‘haptic’ graphics—i.e. those with a texture people can touch and feel—will take off in the future. And just like visual graphics, textural surfaces can be personalized and customized.

Examples include specially deposited inks on glass and ceramics, along with wood laminates. Previously, these types of surfaces could be printed to simulate a texture visually, but did not feel ‘right.’ Now, with innovative inkjet printheads inspired by 3-D printing, it is possible to create ‘natural’ effects on walls, décor, white goods and other surfaces. New ideas will continue to lead to new applications.

Frazer Chesterman is co-founder of FM Brooks, which is part of the Mack Brooks Exhibition Group and organizes InPrint shows, including the upcoming InPrint USA, to be held in April 2017 in Orlando, Fla. He was previously managing director for the Federation of European Screen Printers Associations’ (FESPA’s) wide-format exhibitions. This article is based on a seminar he presented at the International Sign Association’s (ISA’s) 2016 International Sign Expo. For more information, contact him via e-mail at frazer.chesterman@mackbrooks.com[1] and visit www.inprintshow.com[2] and www.signs.org[3].

- frazer.chesterman@mackbrooks.com: mailto:frazer.chesterman@mackbrooks.com

- www.inprintshow.com: http://www.inprintshow.com

- www.signs.org: http://www.signs.org

Source URL: https://www.signmedia.ca/wide-format-graphics-the-industrial-printing-revolution/