Wide-format Graphics: Vehicle wraps from design to installation

by all | 25 May 2015 3:51 pm

[1]

[1]Photo courtesy Roland DGA

By Peter Saunders

Richard Childress Racing (RCR) recently kicked off the 2015 National Association for Stock Car Racing (NASCAR) season with new race car wraps at Daytona International Speedway in Daytona Beach, Fla. The team built significant momentum last year, with its star driver Ryan Newman finishing in second place—by less than one second—at the season finale at Homestead-Miami Speedway in Homestead, Fla. Its sponsors remain the same this year, including Cheerios, Dow, Caterpillar and Quicken Loans; but their brands are featured in newly designed wraps, produced with eight Roland DGA wide-format digital inkjet printers.

“When it comes to new wrap concepts, we may need to create 20 different variations of a design for a sponsor to choose from,” explains Nick Woodward, RCR’s graphics manager, who oversees the process in a 232-m2 (2,500-sf) facility in Welcome, N.C. “We print and install a new wrap for every one of our cars prior to each race. During the course of an average season, we’ll complete approximately 325 full vehicle wraps, using more than 9,197 m2 (99,000 sf) of media.”

The current season started in mid-February, but Woodward’s crew started focusing on graphic design work last August and continued throughout the fall, to get a head start. During the racing season, wrap production and installation keep the technicians equally busy. And in addition to wrapping RCR race cars, they also wrap various support and transport vehicles and equipment used in the pit.

“Our wraps play a major role in RCR’s overall promotional plan, so each one needs to be perfect,” says Woodward. “The printers we use are fast, reliable and precise, allowing us to complete all of our jobs on time and get everything from the corporate colours to the smallest details of logos just right.”

RCR and Roland began working together in 2010. With a recent renewal of their partnership, their collaboration will continue through at least 2019, yielding hundreds more car wraps that will be seen by fans in the stands and viewers around the world. Such visibility only makes it all the more important to perfect the art of each wrap, from design through production to installation.

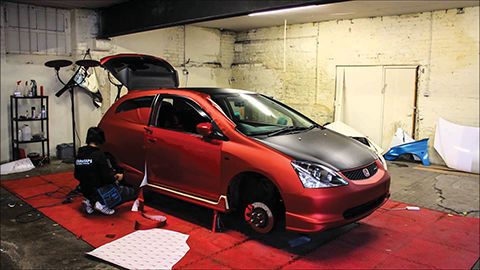

[2]

[2]Wrapping instructor Justin Pate decorate this car with patterned graphics for his mother. Photo courtesy Justin Pate

Design

Most vehicle wraps never race down a track or are seen by international viewers, but some of the fundamentals of successful design remain the same. According to Rob Ivers—a vinyl installation trainer and one of the directors of the Specialty Graphic Imaging Association’s (SGIA’s) Professional Decal Application Alliance (PDAA)—the first step of a successful wrap lies with the designer, long before the more obvious challenges of installation.

JMR Graphics, a 3M-certified manufacturer of commercial vehicle wraps, emphasizes the following three characteristics, explaining they can help turn passersby into customers of an advertised business.

1. A design that complements the vehicle’s dimensions.

A graphic design concept might look great on paper or computer screen, but if it does not complement the dimensions, contours, curves and rivets of the vehicle to which it will be

applied, it can end up looking unprofessional in the end, detracting from the brand and

message.

[3]

[3]Vinyl films applied to horizontal portions of the vehicle will face greater durability challenges than those on the front, sides and back. Photo courtesy Mactac

As experienced vehicle wrap designers understand, the three-dimensional (3-D) nature of graphics wrapped around cars are more complex than the two-dimensional (2-D) designs of many other wide-format printed graphics. Fortunately, templates are readily available for almost any make, model and year, but even then, the same edition of a vehicle may come in different sizes and with different external accessories. So, it is important to check on and incorporate all custom details of the intended application surface into the design.

Further, it is worthwhile to consider how the wrap will appear when the vehicle’s doors and windows are opened and if the gas cap, door seams or any other features will break the visual flow of imagery or text.

2. Text that can be read quickly.

In most situations, people only have a few seconds to read the text on a vehicle wrap. They will certainly not be able to read small text moving at 105 km/h (65 mph) along a highway, let alone NASCAR speeds.

Simple text that is large and bold will work best. This is especially key when designing a marketer’s ‘call to action’ and contact details for the advertised business.

3. High-resolution images.

Unlike billboards, among other types of wide-format graphics, most vehicle wraps are seen both from a distance and close up. For this reason, only high-resolution vector graphics will work well on cars and trucks.

Advertisers should never have to settle for a low-quality vehicle wrap. Their one-time investment in the right combination of text and graphics should yield years of effective marketing and promotion.

[4]

[4]Some vinyl films are meant specifically for decals and markings, while others are engineered for full wraps. Photos courtesy Roland DGA

Echoing the likes of Ivers, wrapping instructor Justin Pate emphasizes certain design fundamentals that will make installation more efficient. He requests neutral colour transitions on corners, for example, and asks for door handles to match the backdrop colour.

“These aspects of design will help make the graphics look like they are all seamlessly connected, even though they are actually applied in different panels,” he explains. “You should also consider the colour of the vehicle and incorporate that into the design. Then you can leave some gaps and have other parts of the graphics match that colour.”

Indeed, Pate—who has wrapped more than 3,000 vehicles, mostly by himself, since beginning his career in 1996—suggests letting the installer approve the design, as a few tweaks may result in a better, more efficient process.

Media selection

While the use of vehicle graphics has become commonplace, concerns remain that relate to both conceptual design and physical durability. If they are to achieve their goals of driving brand awareness and sales, they must withstand the constant tests of high and low temperatures, ultraviolet (UV) radiation, rain, dew, snow, humidity, abrasion and other harsh environmental conditions that could lead to discoloration.

“The horizontal portion of a vehicle is generally of the most concern, as vinyl graphics face the most durability challenges there,” says Jason Yard, marketing manager for pressure-sensitive adhesive film manufacturer Mactac. “The roof and hood are exposed to the elements more directly than the sides of the vehicle and, for this reason, are often the first portions to fail.”

Wrap films are tested in weatherability simulations, which can use special environmental chambers and instruments to accelerate the weathering process and then measure its effects to get a relatively accurate indication of how the films will perform in real-world climate conditions.

[5]

[5]Increasing efficiency in wrap installation is simply a matter of continuous learning.

“A recent test of one of our products showed higher resistance to UV aging than a comparable product, which began cracking after 6,400 hours,” says Yard. “General performance of overlaminates applied to the printed media was also tested, but little variance was found between the two samples. This highlights why it is important to look at different attributes of materials.”

Some vinyl films are meant specifically for decals and markings, while others are engineered for full wraps. Options include permanent or easily removable adhesives. The degree of curvature of the vehicle will also determine which film is best-suited for the application, as it is important to avoid bubbles along the surface.

“Don’t try to use one film for everything,” says Pate. “Some films are too thick, for example, to wrap the recessed areas on a Mercedes-Benz Sprinter van. You need to mix and match.”

The adhesive’s performance will also depend on the right approach to installation and maintenance. Temperatures between 15 and 35 C (59 and 95 F) will typically allow the adhesive to flow and build a sufficient bond.

Production

Like design, the production of vehicle graphics should also take installation into consideration. Downloading or creating the right printer profile, for example, is key in ensuring the right amount of ink is laid down on the film during printing, so the graphics will be light and dry for wrapping, not too tacky. Similarly, when printing with solvent-based inks, it is important to allow sufficient time for the graphics to outgas properly before installation.

“Too many people only outgas the graphics for 12 hours, then laminate them,” says Pate. “The solvents continue to outgas, but into the adhesive, which will slow down the installation process.”

As for lamination, while a thick layer may work well on box trucks and other relatively flat vehicle surfaces for wraps, thinner is better for cars, given their contours. A thick combination of film and laminate will be slower to wrap, especially on mirrors and bumpers.

Similarly, graphic panels should be sized and printed with the intended vehicle in mind. Pate recommends vertical panels for box trucks and semi-trailers and horizontal panels for vans and sedans.

[6]

[6]Richard Childress Racing (RCR) prints and installs new wraps for each of its cars before every race.

“At the beginning, everyone used vertical panels for everything because the adhesives were too aggressive to reposition, but they were slow to install because each panel had to be trimmed out quite specifically,” he says. “I now prefer horizontal panels because there is less need to register the graphics to the vehicle. Vertical panels are still better for trucks because it would be more difficult to position long, horizontal panels. And sometimes, depending on the vehicle, a mix of vertical and horizontal panels is best.”

He also recommends printing on 1.5-m (60-in.) wide films, as then a single panel can span the height of a sedan. Some sign shops instead use 1.37-m (54-in.) wide films, which may necessitate printing multiple horizontal panels for the same section of a car, or 1.2-m (48-in.) films, in which case vertical panels may be needed even to wrap a small sedan, spaced out based on breaks for the doors.

“Considering these factors in the design can make perfect registration of the graphics much easier,” says Pate. “The panels should be labelled on the graphic side, rolled up in sequential order and given to the installer with a printed layout indicating which panel goes where. All too often, I have to wrap a whole bus and I have no layout, so I have to physically space out the panels, which is very time-consuming.”

Installation

To a large degree, Pate’s career as an installer and educator has focused on improving the efficiency of the wrapping process. He says this is not so much a matter of speed as of preventing failures and optimizing quality.

“Quality and durability have to come first and about 80 per cent of the game is knowing how best to squeegee, cut and heat the graphics,” he says. “Fleets are a great way to become efficient through sheer repetition. And starting with the right tools is the best way to reduce mistakes.”

Beyond squeegees, cutting knives and heat guns, Pate recommends application gloves, a tool belt, an edge sealer, stud magnets and a ‘micro-squeegee’ for tucking vinyl under rubber. And as wrapping can be strenuous, he suggests keeping one’s health in mind, too.

“I treat wrapping like a sport, so I keep water and powders on hand to keep my electrolytes up and snacks for energy,” he says. “Keeping in good shape allows you to wrap a lot of cars.”

Once the vehicle has been cleaned with soap, water and a 70 per cent isopropyl alcohol for degreasing (anything stronger could risk hazing the paint), Pate recommends wrapping in this sequential order: hood, roof, sides, back, mirrors, door handles and bumpers.

“There are times to wrap fast and key points where you need to slow down,” he says.

As mentioned earlier, temperature is an important factor when wrapping. A vehicle normally parked outdoors in the winner should be stored indoors the night before wrapping to allow it to warm up.

“If possible, use a portable heater to direct the warm air to speed up the process,” says Mactac’s Yard. “It is also a good idea to keep the printed graphics in a temperature-controlled environment, pulling them out just when they are needed.”

Pate says the ‘sweet spot’ is above 16 C (60 F) and below 24 C (75 F)—any colder and the film can become stiff, brittle and difficult to stretch, any warmer and it can become gooey and tacky.

“For the same reason, avoid applying too much heat with the gun,” he says. “If you understand the film and use technique, you can use less heat to achieve a solid wrap. The best installers constantly learn and get better because they are open to new tools, techniques and films. And they always look for efficiency because it can come from unexpected places.”

Maintenance

After a wrap is installed, maintenance can make a difference in how long it lasts. The adhesives should first be allowed to cure for at least three days before hand-washing the vehicle or a full week before machine- or pressure-washing.

“When cleaning, use soft cloths and non-abrasive cleaners to avoid damaging the wrap,” says Mactac’s Yard, “and if you’re using a polish or wax to enhance the lifespan of the wrap, use only vinyl-friendly products.”

[7]

[7]There is a growing market for restyling cars with colour-change films. Photo courtesy GStar Wraps

Restyling

One growing area of the wrap business involves restyling customers’ cars with colour-change films, which have become available in an ever-wider variety of colours and finishes. While this type of work can provide a new revenue stream for sign and graphics companies, it requires a very different mindset.

“A commercial wrap is usually for the purpose of advertising, turning a vehicle into a ‘moving billboard,’” says Ritchie Daize, automotive sales representative for film manufacturer Arlon Graphics. “The most important aspects, in order of priority, are utility, longevity and curb appeal. So, it should be as easy to install as possible. A colour change wrap’s the opposite; curb appeal is the most important factor, followed by longevity and finally utility. It’s a fashion accessory. People don’t need it, they want it.”

“In the last five years, colour-change wraps have really changed the market with a different approach,” says Pate. “You don’t need a printer or a laminator, it’s like a business in a box, but the wrapping takes longer and if you rush it, it’s easy to make mistakes.”

While a commercial graphic wrap typically takes eight hours (or less than five for Pate), Daize estimates three to five days are needed for a full restyling wrap.

“So, customers may need to leave their car at the shop for a week,” he says. “The work involves the same basic skills as commercial wrapping, but the films are thicker and every detail needs to emulate an original equipment manufacturer (OEM) automotive finish. The most difficult and time-consuming is a chrome wrap. And to achieve a perfect paint-like finish, you have to leave no evidence of the original paint colour.”

With that in mind, it is all the more important before wrapping to remove the side-view mirrors, antenna, bumper and other ‘hardware,’ as the customer will expect the entire vehicle to display a uniform colour afterwards.

“I use professional mechanics for that work the night before the wrap, then have them put everything back on afterwards,” says Pate. “It’s what they’re trained to do and that leaves me with more energy for the installation.”

“Some colour change experts dismantle cars down to the basic body,” says Daize. “The further you go, the greater the liability and the cost for labour over the course of the week.”

The customer may also have expectations with regard to the interior of the vehicle. In the vast majority of cases, a colour change film is simply wrapped to the exterior and tucked slightly into the doors, but some clients will request a full wrap inside and out.

“Then your price has to double, as you need more material and it takes at least twice as long to install,” says Pate.

[8]

[8]Under certain circumstances, it is possible to print graphics on colour-change restyling films. Photo courtesy Arlon Graphics

In any case, Daize recommends a lift to raise the vehicle and separate stands to hold the doors and bumpers while they are individually wrapped. Climate control is especially crucial to prevent dust and debris from getting behind the vinyl.

“The tools are different from the sign trade,” says Daize. “An infrared (IR) heater is needed for heating the entire panels of film, for example, rather than a heat gun or torch. Colour change films are complicated and layered, so if you overheat or overstretch them, you’ll get a shift in the colour from which you can never recover. Too much heat can also ‘gloss out’ a matte film. The ideal temperature for moving vinyl is between 32 and 38 C (90 and 100 F) and an IR heater can accomplish that without making the installer too hot.”

The IR heater is also important for post-installation heating, which helps the vinyl to ‘relax’ and set into place. Daize recommends post-heating at 42 to 53 C (108 to 127 F).

“With IR, you can post-heat consistently and walk away for a while, rather than have to stand there with your heat gun,” he says. “It’s slower, but it’s the best way to heat the vinyl evenly.”

Despite all of this time-consuming work, colour changes can yield repeat business from car enthusiasts.

“Wrapping exotic cars requires precision, but customers who are keen about restyling will want to change it out again after one or two years,” says Daize. “And after they choose a colour, you can upsell them on accent features.”

Another market, as mentioned with regard to commercial graphics, is fleets.

“There are applications in cargo vans, taxis, security trucks and delivery vans,” says Daize. “In terms of leasing and sales, there’s a cost advantage for them to use colour change films instead of repainting, as restyling reduces the value of the vehicles by less.”

With files from Roland DGA, SGIA, PDAA, JMR Graphics, Justin Pate, The Wrap Institute, Mactac and Arlon Graphics. For more information, visit www.rolanddga.com[9], www.sgia.org[10], www.pdaa.com[11], www.jmrgraphics.com[12], www.justinpate.net[13], www.wrapinstitute.com[14], www.mactac.com[15] and www.wrapitright.com[16].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/rcrcheerios.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/IMG_2424.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/HORIZon_image.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/Roland_Born_to_Wrap_Workshop_2.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/Roland_Born_to_Wrap_Workshop_1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/edit13.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/PhotoCourtesyGStarWraps.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/05/PrintedFace.jpg

- www.rolanddga.com: http://www.rolanddga.com

- www.sgia.org: http://www.sgia.org

- www.pdaa.com: http://www.pdaa.com

- www.jmrgraphics.com: http://www.jmrgraphics.com

- www.justinpate.net: http://www.justinpate.net

- www.wrapinstitute.com: http://www.wrapinstitute.com

- www.mactac.com: http://www.mactac.com

- www.wrapitright.com: http://www.wrapitright.com

Source URL: https://www.signmedia.ca/wide-format-graphics-vehicle-wraps-from-design-to-installation/