7. Not understanding how to calibrate and verify the print target.

With today’s mix of soft and hard proofs, it is easy for a print shop professional to neglect checking whether or not the client’s hard-copy proof submitted with the electronic graphic file is indeed accurate. It may be possible to (a) trust a colour bar or (b) compare the file to the proof, but the best solution is instead to create a new proof from the file internally—with a system known to be accurate—and compare it to what the client submitted.

For such purposes of matching a common offset proof, the relevant industry standard is ISO 12647-7:2013, Graphic Technology—Process Control for the Production of Half-tone Colour Separations, Proof and Production Prints, or American National Standards Institute (ANSI) Committee for Graphic Arts Technologies Standards (CGATS) Characterization Reference Print Condition (CRPC) 7, Typical Extra-large Gamut Printing Processes.

8. Using the wrong configuration.

A configuration is not just a profile; it also encompasses the RIP, the printing resolution, the inks, the substrate and the printer settings. So, if anything changes after a device profile has been set up, then it will produce inaccurate results.

This is why it is important to check the results after any changes to the configuration, to see if those results are still within acceptable tolerances.

9. Not using the correct rendering intent.

The rendering intent is applied in the device profile based on the user’s purposes, so it can vary. Options include colorimetric, relative, saturation and perceptual rendering intents. A relative rendering intent, for example, corrects colour based on the paper being printed.

10. The wrong choice of source profile.

A source profile may be referred to as a CRPC, an input target or just a target profile. If the printer supports a wide colour gamut but the source profile selected is narrow, then colour will be lost along the way. So, it is important to pay attention to the source profile with reference to the expected final results based on the substrate and the gamut of the printing device.

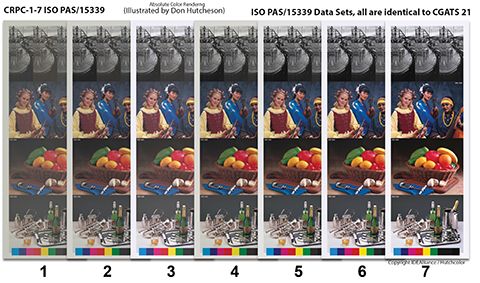

One standard that has been a major success for grand-format printing is ANSI CGATS 21:2013, which covers the unique limitations of different processes and spans a range of colour gamuts for the production of printed materials. Image courtesy Mike Ruff

One standard that has been a major success for the grand-format printing industry, where substrates are rarely as straightforward as white paper, is ANSI CGATS 21:2013, Graphic Technology—Printing from Digital Data Across Multiple Technologies, including Part 1: Principles and Part 2: Reference Characterization Data. Assuming data preparation can be largely process-independent, this standard (a) covers the unique limitations of different processes and (b) specifies seven CRPCs that span a range of colour gamuts used for the production of printed material from digital data, regardless of the particular process.

This way, colour management can allow the choice of printing process to be based on the run length and type of substrate and still achieve the desired appearance in the final graphic product.