Wide-format Printing: Considerations for equipment expansions

by all | 28 July 2017 10:05 am

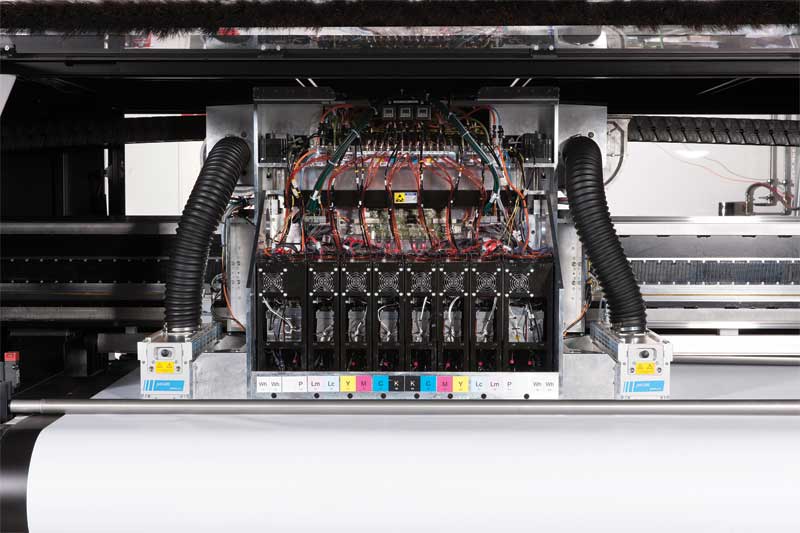

[1]

[1]Photos courtesy Agfa Graphics

By Steve Fournier

There is a broad industry trend today where commercial print service providers (PSPs) are entering the wide-format graphics market. This trend is growing for a number of reasons, including a decline in many traditional print revenue streams, a high level of commoditization for digital small-format printing, newer technologies eating away at profits and the demand among many clients for mass personalization.

By diversifying and adding new services to their business, these print professionals are hoping to establish new revenue streams and ensure their long-term success. A study by the International Sign Association (ISA) found 50 per cent of commercial PSPs have already invested in wide-format systems. This means there are many more yet to make the transition.

Another ‘pull’ factor is the health of the wide-format printing market which, according to an industry forecast by research firm InfoTrends (now part of Keypoint Intelligence), continues to experience a compound annual growth rate (CAGR) of 19 per cent. Every year, new applications and new clients make wide-format graphic production an exciting, evolving business to be in. The market is still wide open.

That said, for those professionals—including signmakers—who are just starting their wide-format journey, there are a number of important considerations as they get into the process. Fortunately, there are also many resources available to help them.

[2]

[2]Vendors well-versed in inks and hardware can help a PSP set realistic goals for entering the wide-format market.

Cost of entry and customer strategy

Too frequently, prospective wide-format printing professionals focus on the financial strategy to purchase an expensive piece of equipment without giving equal thought to their customer strategy. They research their hardware options, attend trade shows, visit manufacturers and existing wide-format print shops, view product demonstrations and undertake benchmark testing before making any decisions.

This capital equipment purchase process can take a year or longer, with the cost of entry for the wide-format market ranging from US$350,000 to US$1.7 million when considering the whole picture, including printing and finishing equipment, plus operations. The undertaking is certainly significant and a highly educational experience for the first-timer.

The learning curve ends up continuing after the equipment is installed, however, once the shop’s staff determines how to optimize its use and, most importantly, how to sell wide-format graphics to customers.

PSPs are counselled instead to put forethought into their customer strategy for wide-format graphics, long before any new equipment is installed. One major difference from commercial printing, for example, is the increasing degree of post-print finishing demanded by clients, a trend that is likely to continue. As such, a new sales strategy will need to be developed, with staff trained to understand which finished products are planned to be produced in which volumes, so as to hit the ground running once the new equipment is operating.

By way of example, a commercial PSP may be looking to purchase a roll-to-roll (RTR) inkjet printer to produce vinyl graphics for point-of-purchase (POP) and outdoor applications. Even if this plan is a great fit for the needs of the shop’s current customer base, aligns with its existing product line and is feasible at the right price point, there is the issue of ensuring a successful post-printing process.

[3]

[3]Floor graphics are among today’s higher-margin applications.

In many cases, printed vinyl output needs to be laminated before it can be sold as an effective application for real-world use. This raises the question of what kind of laminator is needed for the job, which can deliver the right product to the customer at a price that is profitable for the shop.

There are both hot and cold (heat-assist) laminators and their costs differ. A hot laminator operating with heat on both of its rollers is more expensive than a heat-assist laminator, but requires less expensive consumables (i.e. lamination materials). So, the overall volume of output should be analyzed to determine which type of machine will recover its capital investment within a given period. Identifying how much output will be printed and laminated requires an understanding of how the shop’s customers will use wide-format graphics, including short- and long-term applications.

Similarly, if a PSP plans to buy an RTR printer to produce banners, for example, the plan may be based on the assumption of ease of entry and ramping up to profitability, but it is necessary first to think about where, how and why customers will be using those banners. Large volumes may dictate the addition of a roll cutter, a sewing machine (e.g. for pole pockets) and/or a grommet machine to increase the efficiency of post-print finishing and reduce labour costs. Another option is to outsource finishing services to a third-party trade supplier, but the extra costs of those services could erode profits.

Staffing

Any investment in new equipment needs to be coupled with an investment in staff to operate it efficiently. An experienced operator understands colour profiling and other complexities of digital wide-format inkjet printing, will get the best performance out of the equipment and can train other employees accordingly.

It can be hard to find good help in this field, but with the ongoing increase in wide-format graphic production, many operators have already successfully transitioned away from the traditional commercial side of the industry. If they are treated well and given the opportunity to step up to new challenges, the business will grow smoothly.

[4]

[4]Many special effects are now possible, such as varnish (above) and metallic finishes.

Profitable applications

In the wide-format graphics market, gross margins are approximately 50 per cent, with net margins ranging from 10 to 20 per cent, depending on the specific application.

Companies looking for the most profitable growth may want to focus on the higher-margin applications, such as window, wall and floor graphics, soft signage and interior decor, depending on which product line extensions make sense for their business model. Working with vendors with expertise in equipment, inks, media, workflows and support across such applications can help a PSP set short- and long-range goals in this respect.

That said, another option is to grow the business beyond its existing customer base. Growing markets for wide-format graphics include not just the likes of retail, food service and entertainment, but also health care and construction, among others.

Future expectations

Another important consideration is the expected lifespan of the newly purchased equipment. Wide-format printers are typically used for only three to five years before another technology that delivers faster speeds and higher resolutions becomes feasible, while finishing equipment may last for about 10 years. Of course, it is ultimately up to PSP to determine when the business is ready to advance to the next level and upgrade its equipment.

Beyond printing and finishing, there are also in-house business opportunities in kitting and installing wide-format graphics. Again, the needs of the PSP’s customer base will help determine if these opportunities are viable now or at a later date.

In other words, when shops expand into wide-format graphics, it is beneficial to consider all aspects of the process. Wide-format printing may represent a natural extension of a shop’s product line, with the current customer base providing demand for lots of work, but the key is to evaluate how exactly the company will sell those graphics, in which volumes, to which specific customers.

Steve Fournier is a wide-format media and applications business manager for Agfa Graphics, based in Mississauga, Ont. For more information, visit www.agfagraphics.com[5].

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/07/Anapurna-H3200i-LED.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/07/Jeti_Tauro_inks2.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/07/Floor_Graphic-e1501006034920.jpg

- [Image]: https://www.signmedia.ca/wp-content/uploads/2017/07/JetiMira_varnish-.jpg

- www.agfagraphics.com: http://www.agfagraphics.com

Source URL: https://www.signmedia.ca/wide-format-printing-considerations-for-equipment-expansions/